Deck 14: Statistical Applications in Quality Management

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

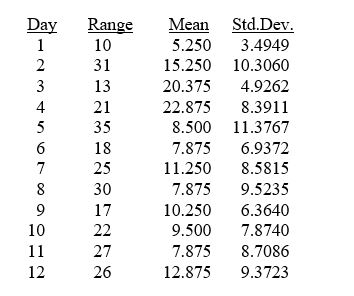

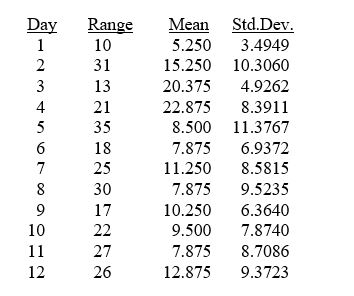

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

فتح الحزمة

قم بالتسجيل لفتح البطاقات في هذه المجموعة!

Unlock Deck

Unlock Deck

1/107

العب

ملء الشاشة (f)

Deck 14: Statistical Applications in Quality Management

1

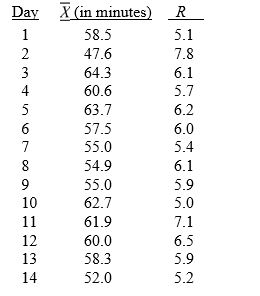

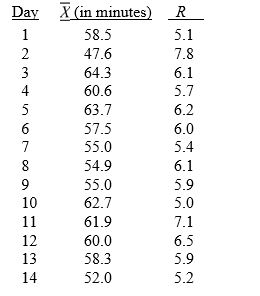

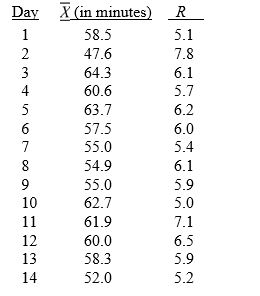

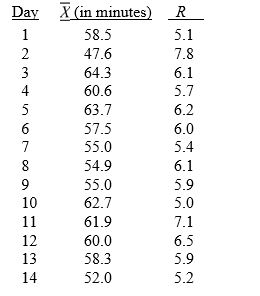

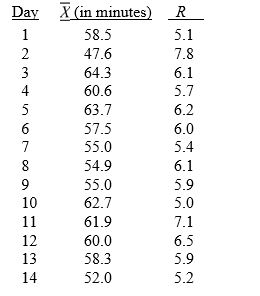

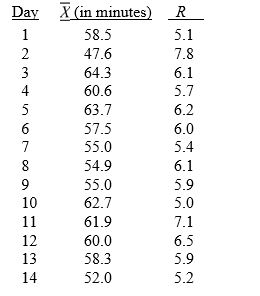

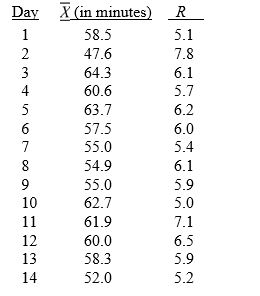

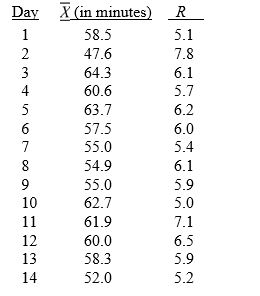

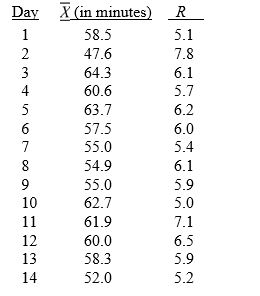

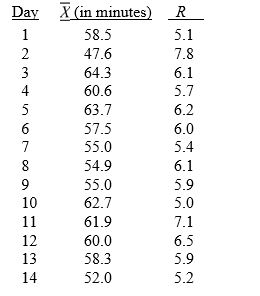

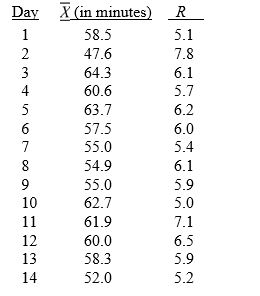

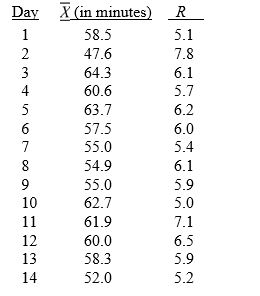

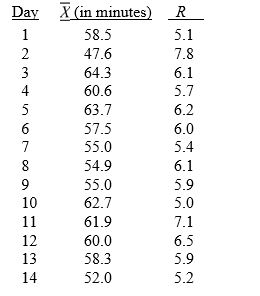

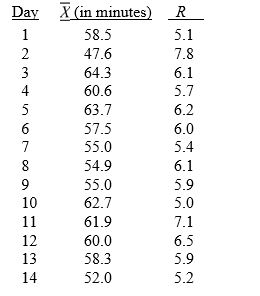

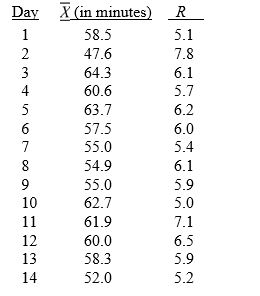

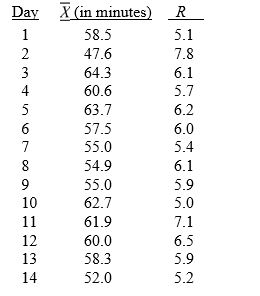

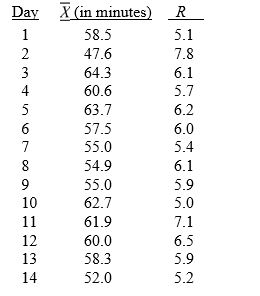

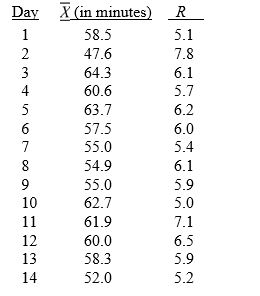

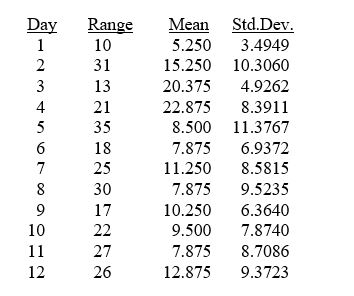

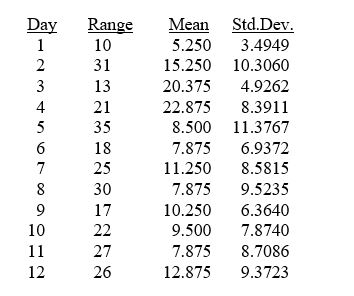

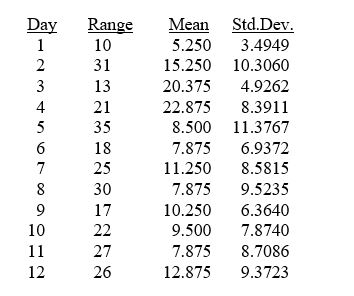

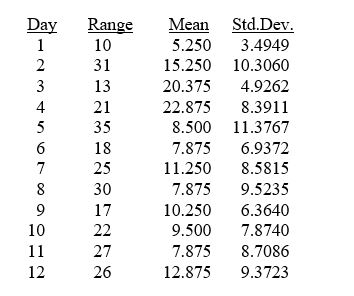

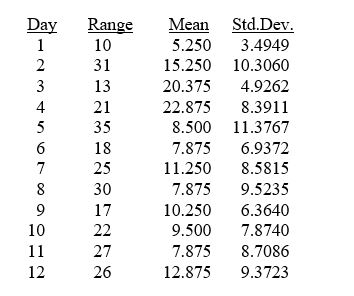

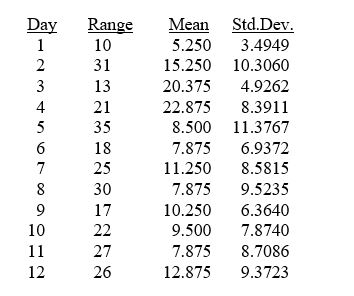

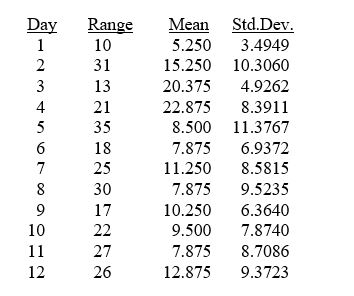

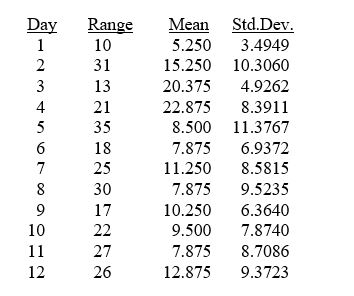

TABLE 14-3

A quality control analyst for a light bulb manufacturer is concerned that the time it takes to produce a batch of light bulbs is too erratic. Accordingly, the analyst randomly surveys 10 production periods each day for 14 days and records the sample mean and range for each day.

Referring to Table 14-3, suppose the analyst constructs an R chart to see if the variability in production times is in control. What is the lower control limit for this R chart?

A) 4.84

B) 3.37

C) 2.98

D) 1.34

A quality control analyst for a light bulb manufacturer is concerned that the time it takes to produce a batch of light bulbs is too erratic. Accordingly, the analyst randomly surveys 10 production periods each day for 14 days and records the sample mean and range for each day.

Referring to Table 14-3, suppose the analyst constructs an R chart to see if the variability in production times is in control. What is the lower control limit for this R chart?

A) 4.84

B) 3.37

C) 2.98

D) 1.34

D

2

TABLE 14-3

A quality control analyst for a light bulb manufacturer is concerned that the time it takes to produce a batch of light bulbs is too erratic. Accordingly, the analyst randomly surveys 10 production periods each day for 14 days and records the sample mean and range for each day.

Referring to Table 14-3, suppose the analyst constructs an R chart to see if the variability in production times is in control. What is the upper control limit for this R chart?

A) 10.66

B) 9.37

C) 7.98

D) 6.34

A quality control analyst for a light bulb manufacturer is concerned that the time it takes to produce a batch of light bulbs is too erratic. Accordingly, the analyst randomly surveys 10 production periods each day for 14 days and records the sample mean and range for each day.

Referring to Table 14-3, suppose the analyst constructs an R chart to see if the variability in production times is in control. What is the upper control limit for this R chart?

A) 10.66

B) 9.37

C) 7.98

D) 6.34

A

3

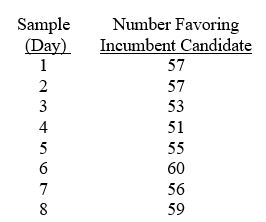

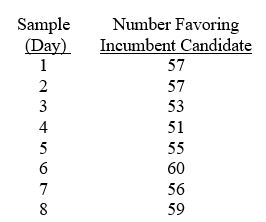

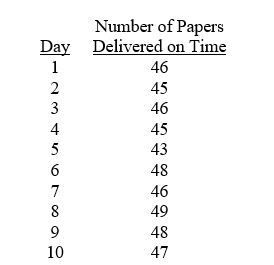

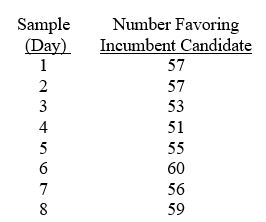

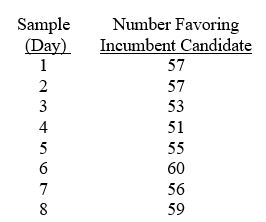

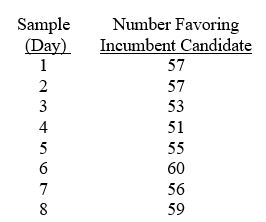

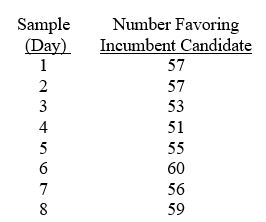

TABLE 14-2

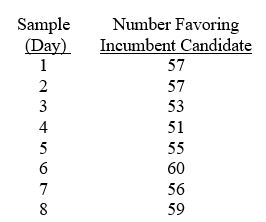

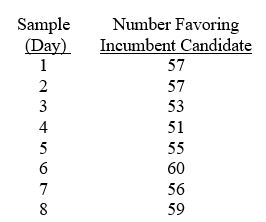

A political pollster randomly selects a sample of 100 voters each day for 8 successive days and asks how many will vote for the incumbent. The pollster wishes to construct a p chart to see if the percentage favoring the incumbent candidate is too erratic.

Referring to Table 14-2, what is the numerical value of the lower control limit for the p chart?

A) 0.37

B) 0.41

C) 0.50

D) 0.71

A political pollster randomly selects a sample of 100 voters each day for 8 successive days and asks how many will vote for the incumbent. The pollster wishes to construct a p chart to see if the percentage favoring the incumbent candidate is too erratic.

Referring to Table 14-2, what is the numerical value of the lower control limit for the p chart?

A) 0.37

B) 0.41

C) 0.50

D) 0.71

B

4

One of the morals of the red bead experiment is:

A) variation is part of the process.

B) only management can change the system.

C) it is the system that primarily determines performance.

D) all of the above

A) variation is part of the process.

B) only management can change the system.

C) it is the system that primarily determines performance.

D) all of the above

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

5

Once the control limits are set for a control chart, one attempts to

A) discern patterns that might exist in values over time.

B) determine whether any points fall outside the control limits.

C) both of the above

D) none of the above

A) discern patterns that might exist in values over time.

B) determine whether any points fall outside the control limits.

C) both of the above

D) none of the above

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

6

Which of the following situations suggests a process that appears to be operating in a state of statistical control?

A) a control chart with a series of consecutive points that are above the center line and a series of consecutive points that are below the center line

B) a control chart in which no points fall outside either the upper control limit or the lower control limit and no patterns are present

C) a control chart in which several points fall outside the upper control limit

D) all of the above

A) a control chart with a series of consecutive points that are above the center line and a series of consecutive points that are below the center line

B) a control chart in which no points fall outside either the upper control limit or the lower control limit and no patterns are present

C) a control chart in which several points fall outside the upper control limit

D) all of the above

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

7

TABLE 14-3

A quality control analyst for a light bulb manufacturer is concerned that the time it takes to produce a batch of light bulbs is too erratic. Accordingly, the analyst randomly surveys 10 production periods each day for 14 days and records the sample mean and range for each day.

Referring to Table 14-3, suppose the analyst constructs an R chart to see if the variability in production times is in control. What is the center line of this R chart?

A) 4.8

B) 6.0

C) 6.9

D) 7.1

A quality control analyst for a light bulb manufacturer is concerned that the time it takes to produce a batch of light bulbs is too erratic. Accordingly, the analyst randomly surveys 10 production periods each day for 14 days and records the sample mean and range for each day.

Referring to Table 14-3, suppose the analyst constructs an R chart to see if the variability in production times is in control. What is the center line of this R chart?

A) 4.8

B) 6.0

C) 6.9

D) 7.1

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

8

The principal focus of the control chart is the attempt to separate special or assignable causes of variation from common causes of variation. Which causes of variation can be reduced only by changing the system?

A) special or assignable causes

B) common causes

C) total causes

D) none of the above

A) special or assignable causes

B) common causes

C) total causes

D) none of the above

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

9

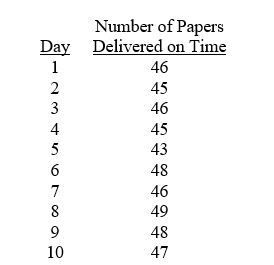

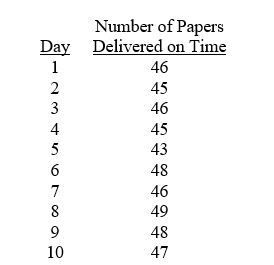

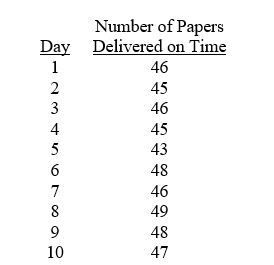

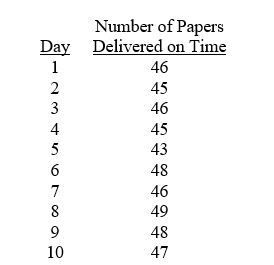

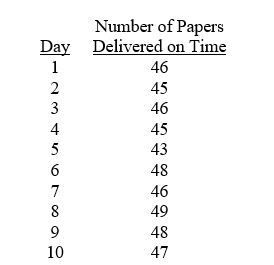

TABLE 14- 1

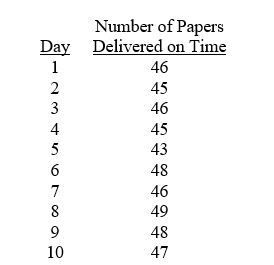

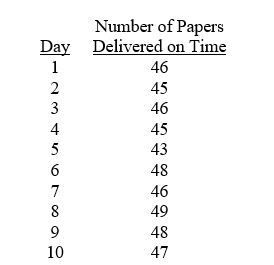

A local newspaper has 10 delivery boys who each deliver the morning paper to 50 customers every day. The owner decides to record the number of papers delivered on time for a 10-day period for one of the delivery boys and construct a p chart to see whether the percentage is too erratic.

Number of Papers

Referring to Table 14-1, what is the numerical value of the lower control limit for the p chart?

A) 0.920

B) 0.911

C) 0.815

D) 0.798

A local newspaper has 10 delivery boys who each deliver the morning paper to 50 customers every day. The owner decides to record the number of papers delivered on time for a 10-day period for one of the delivery boys and construct a p chart to see whether the percentage is too erratic.

Number of Papers

Referring to Table 14-1, what is the numerical value of the lower control limit for the p chart?

A) 0.920

B) 0.911

C) 0.815

D) 0.798

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

10

TABLE 14-2

A political pollster randomly selects a sample of 100 voters each day for 8 successive days and asks how many will vote for the incumbent. The pollster wishes to construct a p chart to see if the percentage favoring the incumbent candidate is too erratic.

Referring to Table 14-2, what is the numerical value of the upper control limit for the p chart?

A) 0.92

B) 0.89

C) 0.71

D) 0.62

A political pollster randomly selects a sample of 100 voters each day for 8 successive days and asks how many will vote for the incumbent. The pollster wishes to construct a p chart to see if the percentage favoring the incumbent candidate is too erratic.

Referring to Table 14-2, what is the numerical value of the upper control limit for the p chart?

A) 0.92

B) 0.89

C) 0.71

D) 0.62

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

11

TABLE 14-2

A political pollster randomly selects a sample of 100 voters each day for 8 successive days and asks how many will vote for the incumbent. The pollster wishes to construct a p chart to see if the percentage favoring the incumbent candidate is too erratic.

Referring to Table 14-2, which expression best characterizes the p chart?

A) in control

B) increasing trend

C) decreasing trend

D) individual outliers

A political pollster randomly selects a sample of 100 voters each day for 8 successive days and asks how many will vote for the incumbent. The pollster wishes to construct a p chart to see if the percentage favoring the incumbent candidate is too erratic.

Referring to Table 14-2, which expression best characterizes the p chart?

A) in control

B) increasing trend

C) decreasing trend

D) individual outliers

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

12

Variation signaled by individual fluctuations or patterns in the data is called

A) special or assignable causes.

B) common or chance causes.

C) explained variation.

D) the standard deviation.

A) special or assignable causes.

B) common or chance causes.

C) explained variation.

D) the standard deviation.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

13

TABLE 14- 1

A local newspaper has 10 delivery boys who each deliver the morning paper to 50 customers every day. The owner decides to record the number of papers delivered on time for a 10-day period for one of the delivery boys and construct a p chart to see whether the percentage is too erratic.

Number of Papers

Referring to Table 14- 1, what is the numerical value of the center line for the p chart?

A) 0.926

B) 0.911

C) 0.885

D) 0.500

A local newspaper has 10 delivery boys who each deliver the morning paper to 50 customers every day. The owner decides to record the number of papers delivered on time for a 10-day period for one of the delivery boys and construct a p chart to see whether the percentage is too erratic.

Number of Papers

Referring to Table 14- 1, what is the numerical value of the center line for the p chart?

A) 0.926

B) 0.911

C) 0.885

D) 0.500

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

14

Variation due to the inherent variability in a system of operation is called

A) special or assignable causes.

B) common or chance causes.

C) explained variation.

D) the standard deviation.

A) special or assignable causes.

B) common or chance causes.

C) explained variation.

D) the standard deviation.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

15

The control chart

A) focuses on the time dimension of a system.

B) captures the natural variability in the system.

C) can be used for categorical, discrete, or continuous variables.

D) all of the above

A) focuses on the time dimension of a system.

B) captures the natural variability in the system.

C) can be used for categorical, discrete, or continuous variables.

D) all of the above

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

16

Which of the following situations suggests a process that appears to be operating out of statistical control?

A) a control chart with a series of consecutive points that are above the center line and a series of consecutive points that are below the center line

B) a control chart in which points fall outside the lower control limit

C) a control chart in which several points fall outside the upper control limit

D) all of the above

A) a control chart with a series of consecutive points that are above the center line and a series of consecutive points that are below the center line

B) a control chart in which points fall outside the lower control limit

C) a control chart in which several points fall outside the upper control limit

D) all of the above

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

17

TABLE 14- 1

A local newspaper has 10 delivery boys who each deliver the morning paper to 50 customers every day. The owner decides to record the number of papers delivered on time for a 10-day period for one of the delivery boys and construct a p chart to see whether the percentage is too erratic.

Number of Papers

Referring to Table 14-1, which expression best characterizes the p chart?

A) cycles

B) increasing trend

C) in control

D) individual outliers

A local newspaper has 10 delivery boys who each deliver the morning paper to 50 customers every day. The owner decides to record the number of papers delivered on time for a 10-day period for one of the delivery boys and construct a p chart to see whether the percentage is too erratic.

Number of Papers

Referring to Table 14-1, which expression best characterizes the p chart?

A) cycles

B) increasing trend

C) in control

D) individual outliers

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

18

A process is said to be out of control if

A) a point falls above the upper or below the lower control lines.

B) eight or more consecutive points fall above the center line or eight or more consecutive points fall below the center line.

C) either of the above

D) none of the above

A) a point falls above the upper or below the lower control lines.

B) eight or more consecutive points fall above the center line or eight or more consecutive points fall below the center line.

C) either of the above

D) none of the above

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

19

TABLE 14- 1

A local newspaper has 10 delivery boys who each deliver the morning paper to 50 customers every day. The owner decides to record the number of papers delivered on time for a 10-day period for one of the delivery boys and construct a p chart to see whether the percentage is too erratic.

Number of Papers

Referring to Table 14-1, what is the numerical value of the upper control limit for the p chart?

A) 0.926

B) 0.961

C) 0.979

D) 1.037

A local newspaper has 10 delivery boys who each deliver the morning paper to 50 customers every day. The owner decides to record the number of papers delivered on time for a 10-day period for one of the delivery boys and construct a p chart to see whether the percentage is too erratic.

Number of Papers

Referring to Table 14-1, what is the numerical value of the upper control limit for the p chart?

A) 0.926

B) 0.961

C) 0.979

D) 1.037

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

20

TABLE 14-2

A political pollster randomly selects a sample of 100 voters each day for 8 successive days and asks how many will vote for the incumbent. The pollster wishes to construct a p chart to see if the percentage favoring the incumbent candidate is too erratic.

Referring to Table 14-2, what is the numerical value of the center line for the p chart?

A) 0.53

B) 0.56

C) 0.63

D) 0.66

A political pollster randomly selects a sample of 100 voters each day for 8 successive days and asks how many will vote for the incumbent. The pollster wishes to construct a p chart to see if the percentage favoring the incumbent candidate is too erratic.

Referring to Table 14-2, what is the numerical value of the center line for the p chart?

A) 0.53

B) 0.56

C) 0.63

D) 0.66

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

21

TABLE 14-4

A factory supervisor is concerned that the time it takes workers to complete an important production task (measured in seconds) is too erratic and adversely affects expected profits. The supervisor proceeds by randomly sampling 5 individuals per hour for a period of 10 hours. The sample mean and range for each hour are listed below.

She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds, respectively.

Referring to Table 14-4, suppose the supervisor constructs an chart to see if the process is in control. What are the lower and upper control limits of this chart?

chart to see if the process is in control. What are the lower and upper control limits of this chart?

A) 10.00, 30.00

B) 8.49, 32.03

C) 5.39, 35.13

D) 4.96, 35.56

A factory supervisor is concerned that the time it takes workers to complete an important production task (measured in seconds) is too erratic and adversely affects expected profits. The supervisor proceeds by randomly sampling 5 individuals per hour for a period of 10 hours. The sample mean and range for each hour are listed below.

She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds, respectively.

Referring to Table 14-4, suppose the supervisor constructs an

chart to see if the process is in control. What are the lower and upper control limits of this chart?

chart to see if the process is in control. What are the lower and upper control limits of this chart?A) 10.00, 30.00

B) 8.49, 32.03

C) 5.39, 35.13

D) 4.96, 35.56

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

22

TABLE 14-4

A factory supervisor is concerned that the time it takes workers to complete an important production task (measured in seconds) is too erratic and adversely affects expected profits. The supervisor proceeds by randomly sampling 5 individuals per hour for a period of 10 hours. The sample mean and range for each hour are listed below.

She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds, respectively.

The purpose of a control chart is to eliminate common cause variation.

A factory supervisor is concerned that the time it takes workers to complete an important production task (measured in seconds) is too erratic and adversely affects expected profits. The supervisor proceeds by randomly sampling 5 individuals per hour for a period of 10 hours. The sample mean and range for each hour are listed below.

She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds, respectively.

The purpose of a control chart is to eliminate common cause variation.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

23

TABLE 14-4

A factory supervisor is concerned that the time it takes workers to complete an important production task (measured in seconds) is too erratic and adversely affects expected profits. The supervisor proceeds by randomly sampling 5 individuals per hour for a period of 10 hours. The sample mean and range for each hour are listed below.

She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds, respectively.

Referring to Table 14-4, what is the value of d₂ factor?

A factory supervisor is concerned that the time it takes workers to complete an important production task (measured in seconds) is too erratic and adversely affects expected profits. The supervisor proceeds by randomly sampling 5 individuals per hour for a period of 10 hours. The sample mean and range for each hour are listed below.

She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds, respectively.

Referring to Table 14-4, what is the value of d₂ factor?

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

24

TABLE 14-4

A factory supervisor is concerned that the time it takes workers to complete an important production task (measured in seconds) is too erratic and adversely affects expected profits. The supervisor proceeds by randomly sampling 5 individuals per hour for a period of 10 hours. The sample mean and range for each hour are listed below.

She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds, respectively.

Referring to Table 14-4, suppose the supervisor constructs an R chart to see if the variability in collection times is in control. What are the lower and upper control limits for this R chart?

A) -2.33, 43.13

B) -2.28, 42.28

C) 0, 42.28

D) 0, 43.13

A factory supervisor is concerned that the time it takes workers to complete an important production task (measured in seconds) is too erratic and adversely affects expected profits. The supervisor proceeds by randomly sampling 5 individuals per hour for a period of 10 hours. The sample mean and range for each hour are listed below.

She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds, respectively.

Referring to Table 14-4, suppose the supervisor constructs an R chart to see if the variability in collection times is in control. What are the lower and upper control limits for this R chart?

A) -2.33, 43.13

B) -2.28, 42.28

C) 0, 42.28

D) 0, 43.13

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

25

TABLE 14-4

A factory supervisor is concerned that the time it takes workers to complete an important production task (measured in seconds) is too erratic and adversely affects expected profits. The supervisor proceeds by randomly sampling 5 individuals per hour for a period of 10 hours. The sample mean and range for each hour are listed below.

She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds, respectively.

The control limits are based on the standard deviation of the process.

A factory supervisor is concerned that the time it takes workers to complete an important production task (measured in seconds) is too erratic and adversely affects expected profits. The supervisor proceeds by randomly sampling 5 individuals per hour for a period of 10 hours. The sample mean and range for each hour are listed below.

She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds, respectively.

The control limits are based on the standard deviation of the process.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

26

TABLE 14-4

A factory supervisor is concerned that the time it takes workers to complete an important production task (measured in seconds) is too erratic and adversely affects expected profits. The supervisor proceeds by randomly sampling 5 individuals per hour for a period of 10 hours. The sample mean and range for each hour are listed below.

She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds, respectively.

Special or assignable causes of variation are signaled by individual fluctuations or patterns in the data.

A factory supervisor is concerned that the time it takes workers to complete an important production task (measured in seconds) is too erratic and adversely affects expected profits. The supervisor proceeds by randomly sampling 5 individuals per hour for a period of 10 hours. The sample mean and range for each hour are listed below.

She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds, respectively.

Special or assignable causes of variation are signaled by individual fluctuations or patterns in the data.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

27

TABLE 14-4

A factory supervisor is concerned that the time it takes workers to complete an important production task (measured in seconds) is too erratic and adversely affects expected profits. The supervisor proceeds by randomly sampling 5 individuals per hour for a period of 10 hours. The sample mean and range for each hour are listed below.

She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds, respectively.

Referring to Table 14-4, suppose the supervisor constructs an chart to see if the process is in control. Which expression best describes this chart?

chart to see if the process is in control. Which expression best describes this chart?

A) decreasing trend

B) in control

C) increasing trend

D) individual outliers

A factory supervisor is concerned that the time it takes workers to complete an important production task (measured in seconds) is too erratic and adversely affects expected profits. The supervisor proceeds by randomly sampling 5 individuals per hour for a period of 10 hours. The sample mean and range for each hour are listed below.

She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds, respectively.

Referring to Table 14-4, suppose the supervisor constructs an

chart to see if the process is in control. Which expression best describes this chart?

chart to see if the process is in control. Which expression best describes this chart?A) decreasing trend

B) in control

C) increasing trend

D) individual outliers

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

28

TABLE 14-3

A quality control analyst for a light bulb manufacturer is concerned that the time it takes to produce a batch of light bulbs is too erratic. Accordingly, the analyst randomly surveys 10 production periods each day for 14 days and records the sample mean and range for each day.

Referring to Table 14-3, suppose the analyst constructs an chart to see if the production process is in control. What is the upper control limit (UCL)for this chart?

chart to see if the production process is in control. What is the upper control limit (UCL)for this chart?

A) 62.15

B) 60.95

C) 59.85

D) 58.75

A quality control analyst for a light bulb manufacturer is concerned that the time it takes to produce a batch of light bulbs is too erratic. Accordingly, the analyst randomly surveys 10 production periods each day for 14 days and records the sample mean and range for each day.

Referring to Table 14-3, suppose the analyst constructs an

chart to see if the production process is in control. What is the upper control limit (UCL)for this chart?

chart to see if the production process is in control. What is the upper control limit (UCL)for this chart?A) 62.15

B) 60.95

C) 59.85

D) 58.75

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

29

TABLE 14-3

A quality control analyst for a light bulb manufacturer is concerned that the time it takes to produce a batch of light bulbs is too erratic. Accordingly, the analyst randomly surveys 10 production periods each day for 14 days and records the sample mean and range for each day.

Referring to Table 14-3, suppose the analyst constructs an chart to see if the production process is in control. What is the lower control limit (LCL)for this chart?

chart to see if the production process is in control. What is the lower control limit (LCL)for this chart?

A) 47.60

B) 56.15

C) 57.15

D) 58.05

A quality control analyst for a light bulb manufacturer is concerned that the time it takes to produce a batch of light bulbs is too erratic. Accordingly, the analyst randomly surveys 10 production periods each day for 14 days and records the sample mean and range for each day.

Referring to Table 14-3, suppose the analyst constructs an

chart to see if the production process is in control. What is the lower control limit (LCL)for this chart?

chart to see if the production process is in control. What is the lower control limit (LCL)for this chart?A) 47.60

B) 56.15

C) 57.15

D) 58.05

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

30

TABLE 14-3

A quality control analyst for a light bulb manufacturer is concerned that the time it takes to produce a batch of light bulbs is too erratic. Accordingly, the analyst randomly surveys 10 production periods each day for 14 days and records the sample mean and range for each day.

Referring to Table 14-3, suppose the sample mean and range data were based on 11 observations per day instead of 10. How would this change affect the lower and upper control limits of the R chart?

A) LCL would increase; UCL would decrease.

B) LCL would remain the same; UCL would decrease.

C) Both LCL and UCL would remain the same.

D) LCL would decrease; UCL would increase.

A quality control analyst for a light bulb manufacturer is concerned that the time it takes to produce a batch of light bulbs is too erratic. Accordingly, the analyst randomly surveys 10 production periods each day for 14 days and records the sample mean and range for each day.

Referring to Table 14-3, suppose the sample mean and range data were based on 11 observations per day instead of 10. How would this change affect the lower and upper control limits of the R chart?

A) LCL would increase; UCL would decrease.

B) LCL would remain the same; UCL would decrease.

C) Both LCL and UCL would remain the same.

D) LCL would decrease; UCL would increase.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

31

TABLE 14-4

A factory supervisor is concerned that the time it takes workers to complete an important production task (measured in seconds) is too erratic and adversely affects expected profits. The supervisor proceeds by randomly sampling 5 individuals per hour for a period of 10 hours. The sample mean and range for each hour are listed below.

She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds, respectively.

Changes in the system to reduce common cause variation are the responsibility of management.

A factory supervisor is concerned that the time it takes workers to complete an important production task (measured in seconds) is too erratic and adversely affects expected profits. The supervisor proceeds by randomly sampling 5 individuals per hour for a period of 10 hours. The sample mean and range for each hour are listed below.

She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds, respectively.

Changes in the system to reduce common cause variation are the responsibility of management.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

32

TABLE 14-4

A factory supervisor is concerned that the time it takes workers to complete an important production task (measured in seconds) is too erratic and adversely affects expected profits. The supervisor proceeds by randomly sampling 5 individuals per hour for a period of 10 hours. The sample mean and range for each hour are listed below.

She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds, respectively.

Common causes of variation represent variation due to the inherent variability in the system.

A factory supervisor is concerned that the time it takes workers to complete an important production task (measured in seconds) is too erratic and adversely affects expected profits. The supervisor proceeds by randomly sampling 5 individuals per hour for a period of 10 hours. The sample mean and range for each hour are listed below.

She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds, respectively.

Common causes of variation represent variation due to the inherent variability in the system.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

33

TABLE 14-3

A quality control analyst for a light bulb manufacturer is concerned that the time it takes to produce a batch of light bulbs is too erratic. Accordingly, the analyst randomly surveys 10 production periods each day for 14 days and records the sample mean and range for each day.

Referring to Table 14-3, suppose the analyst constructs an R chart to see if the variability in production times is in control. The R chart is characterized by which of the following?

A) increasing trend

B) decreasing trend

C) in control

D) points outside the control limits

A quality control analyst for a light bulb manufacturer is concerned that the time it takes to produce a batch of light bulbs is too erratic. Accordingly, the analyst randomly surveys 10 production periods each day for 14 days and records the sample mean and range for each day.

Referring to Table 14-3, suppose the analyst constructs an R chart to see if the variability in production times is in control. The R chart is characterized by which of the following?

A) increasing trend

B) decreasing trend

C) in control

D) points outside the control limits

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

34

TABLE 14-4

A factory supervisor is concerned that the time it takes workers to complete an important production task (measured in seconds) is too erratic and adversely affects expected profits. The supervisor proceeds by randomly sampling 5 individuals per hour for a period of 10 hours. The sample mean and range for each hour are listed below.

She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds, respectively.

Referring to Table 14-4, suppose the sample mean and range data were based on 6 observations per hour instead of 5. How would this change affect the lower and upper control limits of an R chart?

A) LCL would increase; UCL would decrease.

B) LCL would remain the same; UCL would decrease.

C) Both LCL and UCL would remain the same.

D) LCL would decrease; UCL would increase.

A factory supervisor is concerned that the time it takes workers to complete an important production task (measured in seconds) is too erratic and adversely affects expected profits. The supervisor proceeds by randomly sampling 5 individuals per hour for a period of 10 hours. The sample mean and range for each hour are listed below.

She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds, respectively.

Referring to Table 14-4, suppose the sample mean and range data were based on 6 observations per hour instead of 5. How would this change affect the lower and upper control limits of an R chart?

A) LCL would increase; UCL would decrease.

B) LCL would remain the same; UCL would decrease.

C) Both LCL and UCL would remain the same.

D) LCL would decrease; UCL would increase.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

35

TABLE 14-4

A factory supervisor is concerned that the time it takes workers to complete an important production task (measured in seconds) is too erratic and adversely affects expected profits. The supervisor proceeds by randomly sampling 5 individuals per hour for a period of 10 hours. The sample mean and range for each hour are listed below.

She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds, respectively.

Common causes of variation are correctable without modifying the system.

A factory supervisor is concerned that the time it takes workers to complete an important production task (measured in seconds) is too erratic and adversely affects expected profits. The supervisor proceeds by randomly sampling 5 individuals per hour for a period of 10 hours. The sample mean and range for each hour are listed below.

She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds, respectively.

Common causes of variation are correctable without modifying the system.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

36

TABLE 14-4

A factory supervisor is concerned that the time it takes workers to complete an important production task (measured in seconds) is too erratic and adversely affects expected profits. The supervisor proceeds by randomly sampling 5 individuals per hour for a period of 10 hours. The sample mean and range for each hour are listed below.

She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds, respectively.

Referring to Table 14-4, suppose the supervisor constructs an chart to see if the process is in control. What is the center line of the chart?

chart to see if the process is in control. What is the center line of the chart?

A) 20.00

B) 20.26

C) 21.00

D) 24.26

A factory supervisor is concerned that the time it takes workers to complete an important production task (measured in seconds) is too erratic and adversely affects expected profits. The supervisor proceeds by randomly sampling 5 individuals per hour for a period of 10 hours. The sample mean and range for each hour are listed below.

She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds, respectively.

Referring to Table 14-4, suppose the supervisor constructs an

chart to see if the process is in control. What is the center line of the chart?

chart to see if the process is in control. What is the center line of the chart?A) 20.00

B) 20.26

C) 21.00

D) 24.26

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

37

TABLE 14-4

A factory supervisor is concerned that the time it takes workers to complete an important production task (measured in seconds) is too erratic and adversely affects expected profits. The supervisor proceeds by randomly sampling 5 individuals per hour for a period of 10 hours. The sample mean and range for each hour are listed below.

She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds, respectively.

Referring to Table 14-4, suppose the supervisor constructs an R chart to see if the variability in collection times is in control. This R chart is characterized by which of the following?

A) decreasing trend

B) increasing trend

C) in control

D) individual outliers

A factory supervisor is concerned that the time it takes workers to complete an important production task (measured in seconds) is too erratic and adversely affects expected profits. The supervisor proceeds by randomly sampling 5 individuals per hour for a period of 10 hours. The sample mean and range for each hour are listed below.

She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds, respectively.

Referring to Table 14-4, suppose the supervisor constructs an R chart to see if the variability in collection times is in control. This R chart is characterized by which of the following?

A) decreasing trend

B) increasing trend

C) in control

D) individual outliers

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

38

TABLE 14-3

A quality control analyst for a light bulb manufacturer is concerned that the time it takes to produce a batch of light bulbs is too erratic. Accordingly, the analyst randomly surveys 10 production periods each day for 14 days and records the sample mean and range for each day.

Referring to Table 14-3, suppose the analyst constructs an chart to see if the production process is in control. What is the center line for this chart?

chart to see if the production process is in control. What is the center line for this chart?

A) 64.3

B) 59.5

C) 58.0

D) 57.1

A quality control analyst for a light bulb manufacturer is concerned that the time it takes to produce a batch of light bulbs is too erratic. Accordingly, the analyst randomly surveys 10 production periods each day for 14 days and records the sample mean and range for each day.

Referring to Table 14-3, suppose the analyst constructs an

chart to see if the production process is in control. What is the center line for this chart?

chart to see if the production process is in control. What is the center line for this chart?A) 64.3

B) 59.5

C) 58.0

D) 57.1

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

39

TABLE 14-3

A quality control analyst for a light bulb manufacturer is concerned that the time it takes to produce a batch of light bulbs is too erratic. Accordingly, the analyst randomly surveys 10 production periods each day for 14 days and records the sample mean and range for each day.

Referring to Table 14-3, suppose the analyst constructs an chart to see if the production process is in control. Which expression best describes this chart?

chart to see if the production process is in control. Which expression best describes this chart?

A) in control

B) increasing trend

C) decreasing trend

D) individual outliers

A quality control analyst for a light bulb manufacturer is concerned that the time it takes to produce a batch of light bulbs is too erratic. Accordingly, the analyst randomly surveys 10 production periods each day for 14 days and records the sample mean and range for each day.

Referring to Table 14-3, suppose the analyst constructs an

chart to see if the production process is in control. Which expression best describes this chart?

chart to see if the production process is in control. Which expression best describes this chart?A) in control

B) increasing trend

C) decreasing trend

D) individual outliers

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

40

TABLE 14-4

A factory supervisor is concerned that the time it takes workers to complete an important production task (measured in seconds) is too erratic and adversely affects expected profits. The supervisor proceeds by randomly sampling 5 individuals per hour for a period of 10 hours. The sample mean and range for each hour are listed below.

She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds, respectively.

Referring to Table 14-4, suppose the supervisor constructs an R chart to see if the variability in collection times is in control. What is the center line of this R chart?

A) 20.00

B) 20.56

C) 20.40

D) 24.00

A factory supervisor is concerned that the time it takes workers to complete an important production task (measured in seconds) is too erratic and adversely affects expected profits. The supervisor proceeds by randomly sampling 5 individuals per hour for a period of 10 hours. The sample mean and range for each hour are listed below.

She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds, respectively.

Referring to Table 14-4, suppose the supervisor constructs an R chart to see if the variability in collection times is in control. What is the center line of this R chart?

A) 20.00

B) 20.56

C) 20.40

D) 24.00

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

41

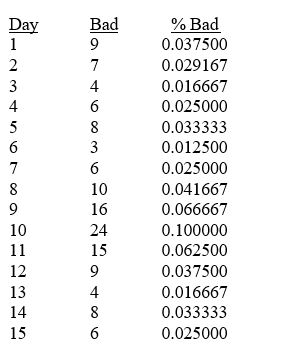

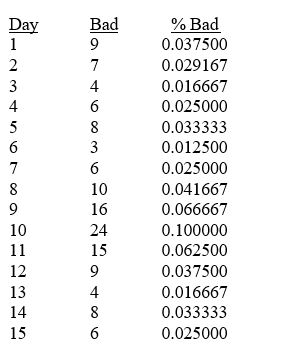

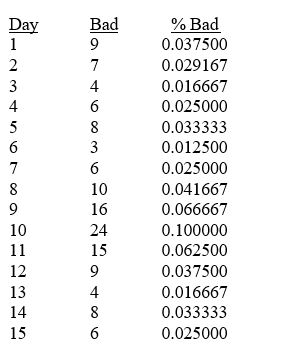

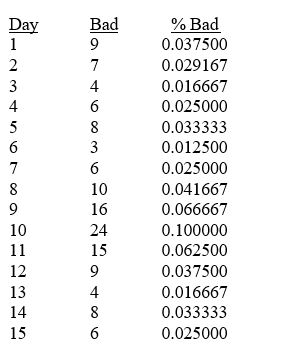

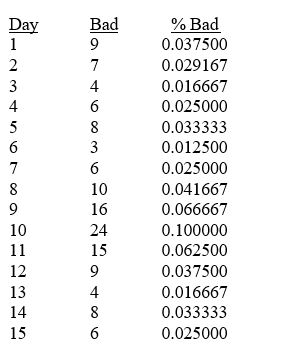

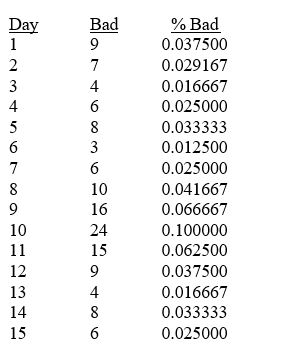

TABLE 14-5

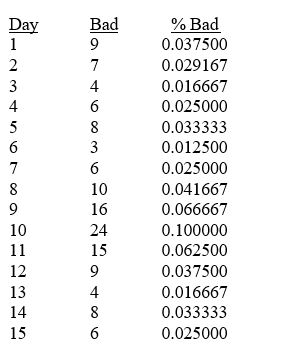

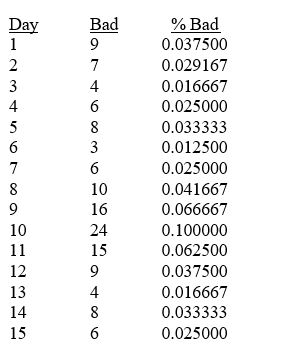

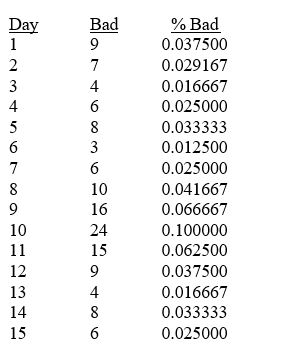

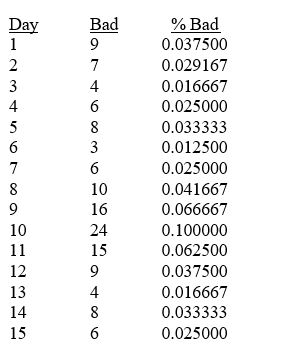

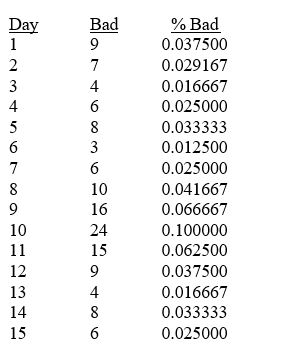

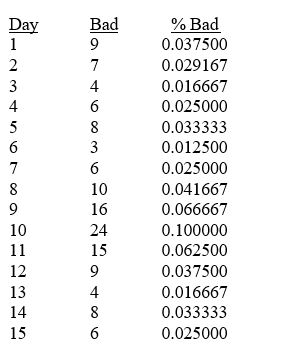

A manufacturer of computer disks took samples of 240 disks on 15 consecutive days. The number of disks with bad sectors was determined for each of these samples. The results are in the table that follows.

Referring to Table 14-5, a p control chart is to be made for these data. The upper control limit is ________, and the lower control limit is ________.

A manufacturer of computer disks took samples of 240 disks on 15 consecutive days. The number of disks with bad sectors was determined for each of these samples. The results are in the table that follows.

Referring to Table 14-5, a p control chart is to be made for these data. The upper control limit is ________, and the lower control limit is ________.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

42

TABLE 14-7

A supplier of silicone sheets for producers of computer chips wants to evaluate her manufacturing process. She takes samples of size 5 from each day's output and counts the number of blemishes on each silicone sheet. The results from 20 days of such evaluations are presented below.

She also decides that the upper specification limit is 10 blemishes.

Referring to Table 14-7, an R chart is to be constructed for the number of blemishes. The center line of this R chart is located at ________.

A supplier of silicone sheets for producers of computer chips wants to evaluate her manufacturing process. She takes samples of size 5 from each day's output and counts the number of blemishes on each silicone sheet. The results from 20 days of such evaluations are presented below.

She also decides that the upper specification limit is 10 blemishes.

Referring to Table 14-7, an R chart is to be constructed for the number of blemishes. The center line of this R chart is located at ________.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

43

TABLE 14-6

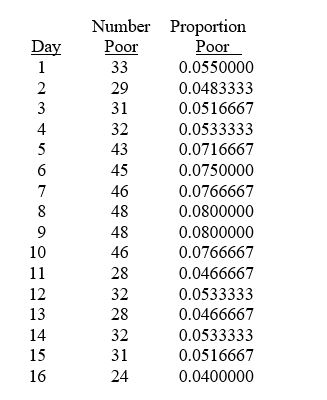

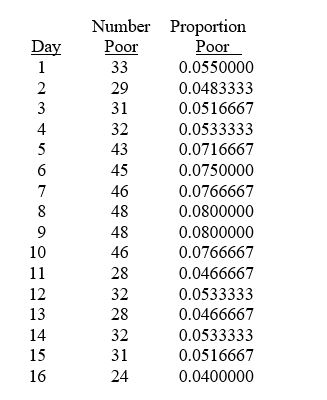

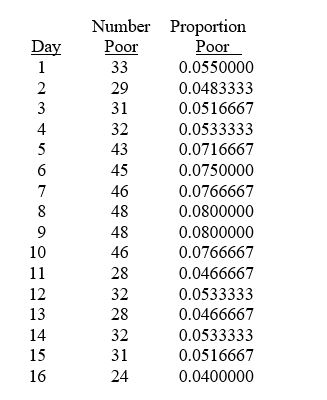

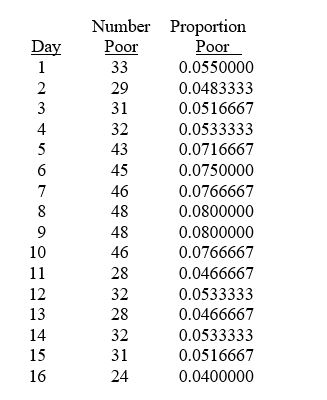

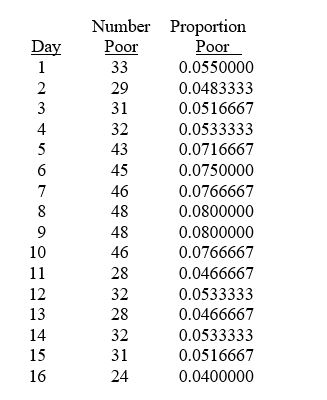

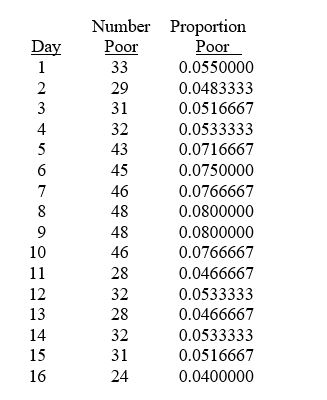

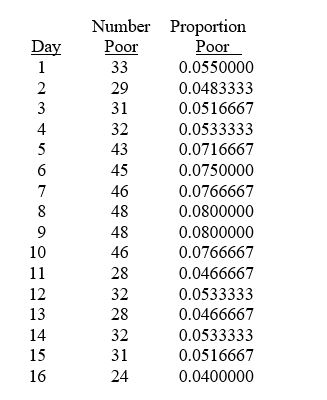

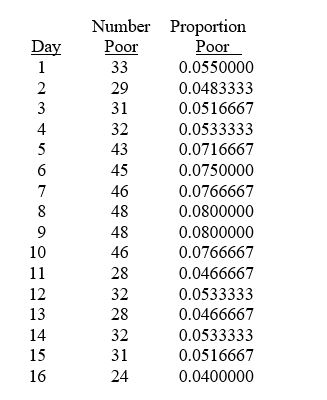

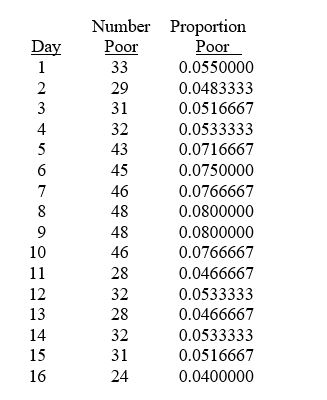

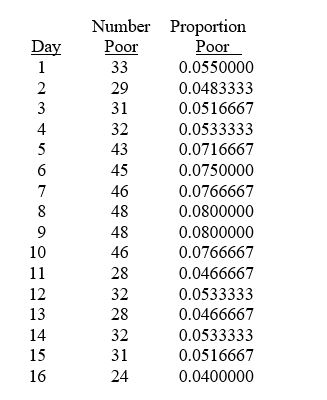

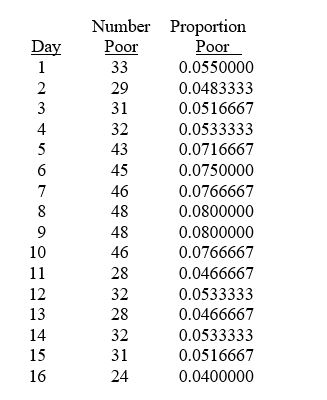

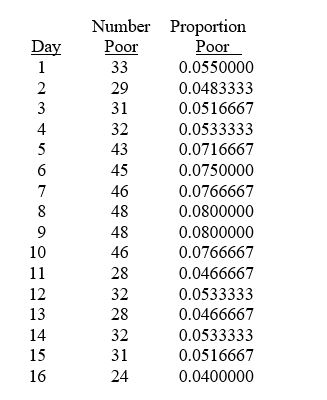

The maker of a packaged candy wants to evaluate the quality of her production process. On each of 16 consecutive days, she samples 600 bags of candy and determines the number in each day's sample that she considers to be of poor quality. The data that she developed follow.

Referring to Table 14-6, construct a p control chart for these data.

The maker of a packaged candy wants to evaluate the quality of her production process. On each of 16 consecutive days, she samples 600 bags of candy and determines the number in each day's sample that she considers to be of poor quality. The data that she developed follow.

Referring to Table 14-6, construct a p control chart for these data.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

44

TABLE 14-4

A factory supervisor is concerned that the time it takes workers to complete an important production task (measured in seconds) is too erratic and adversely affects expected profits. The supervisor proceeds by randomly sampling 5 individuals per hour for a period of 10 hours. The sample mean and range for each hour are listed below.

She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds, respectively.

In the United States, the control limits on a control chart are placed so that they are 3 standard deviations above and below a central line.

A factory supervisor is concerned that the time it takes workers to complete an important production task (measured in seconds) is too erratic and adversely affects expected profits. The supervisor proceeds by randomly sampling 5 individuals per hour for a period of 10 hours. The sample mean and range for each hour are listed below.

She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds, respectively.

In the United States, the control limits on a control chart are placed so that they are 3 standard deviations above and below a central line.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

45

TABLE 14-4

A factory supervisor is concerned that the time it takes workers to complete an important production task (measured in seconds) is too erratic and adversely affects expected profits. The supervisor proceeds by randomly sampling 5 individuals per hour for a period of 10 hours. The sample mean and range for each hour are listed below.

She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds, respectively.

It is not possible for the chart to be out of control when the R chart is in control.

chart to be out of control when the R chart is in control.

A factory supervisor is concerned that the time it takes workers to complete an important production task (measured in seconds) is too erratic and adversely affects expected profits. The supervisor proceeds by randomly sampling 5 individuals per hour for a period of 10 hours. The sample mean and range for each hour are listed below.

She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds, respectively.

It is not possible for the

chart to be out of control when the R chart is in control.

chart to be out of control when the R chart is in control.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

46

TABLE 14-4

A factory supervisor is concerned that the time it takes workers to complete an important production task (measured in seconds) is too erratic and adversely affects expected profits. The supervisor proceeds by randomly sampling 5 individuals per hour for a period of 10 hours. The sample mean and range for each hour are listed below.

She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds, respectively.

The cause of variation that can be reduced only by changing the system is ________ cause variation.

A factory supervisor is concerned that the time it takes workers to complete an important production task (measured in seconds) is too erratic and adversely affects expected profits. The supervisor proceeds by randomly sampling 5 individuals per hour for a period of 10 hours. The sample mean and range for each hour are listed below.

She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds, respectively.

The cause of variation that can be reduced only by changing the system is ________ cause variation.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

47

TABLE 14-5

A manufacturer of computer disks took samples of 240 disks on 15 consecutive days. The number of disks with bad sectors was determined for each of these samples. The results are in the table that follows.

Referring to Table 14-5, a p control chart is to be made for these data. The estimate of the standard error of the proportion of disks with bad sectors is ________.

A manufacturer of computer disks took samples of 240 disks on 15 consecutive days. The number of disks with bad sectors was determined for each of these samples. The results are in the table that follows.

Referring to Table 14-5, a p control chart is to be made for these data. The estimate of the standard error of the proportion of disks with bad sectors is ________.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

48

TABLE 14-5

A manufacturer of computer disks took samples of 240 disks on 15 consecutive days. The number of disks with bad sectors was determined for each of these samples. The results are in the table that follows.

Referring to Table 14-5, the process seems to be in control.

A manufacturer of computer disks took samples of 240 disks on 15 consecutive days. The number of disks with bad sectors was determined for each of these samples. The results are in the table that follows.

Referring to Table 14-5, the process seems to be in control.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

49

TABLE 14-6

The maker of a packaged candy wants to evaluate the quality of her production process. On each of 16 consecutive days, she samples 600 bags of candy and determines the number in each day's sample that she considers to be of poor quality. The data that she developed follow.

Referring to Table 14-6, a p control chart is to be constructed for these data. The estimate of the standard error of the sample proportion is ________.

The maker of a packaged candy wants to evaluate the quality of her production process. On each of 16 consecutive days, she samples 600 bags of candy and determines the number in each day's sample that she considers to be of poor quality. The data that she developed follow.

Referring to Table 14-6, a p control chart is to be constructed for these data. The estimate of the standard error of the sample proportion is ________.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

50

TABLE 14-5

A manufacturer of computer disks took samples of 240 disks on 15 consecutive days. The number of disks with bad sectors was determined for each of these samples. The results are in the table that follows.

Referring to Table 14-5, a p control chart is to be made for these data. The center line of the control chart is ________.

A manufacturer of computer disks took samples of 240 disks on 15 consecutive days. The number of disks with bad sectors was determined for each of these samples. The results are in the table that follows.

Referring to Table 14-5, a p control chart is to be made for these data. The center line of the control chart is ________.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

51

TABLE 14-6

The maker of a packaged candy wants to evaluate the quality of her production process. On each of 16 consecutive days, she samples 600 bags of candy and determines the number in each day's sample that she considers to be of poor quality. The data that she developed follow.

Referring to Table 14-6, the process seems to be in control.

The maker of a packaged candy wants to evaluate the quality of her production process. On each of 16 consecutive days, she samples 600 bags of candy and determines the number in each day's sample that she considers to be of poor quality. The data that she developed follow.

Referring to Table 14-6, the process seems to be in control.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

52

TABLE 14-4

A factory supervisor is concerned that the time it takes workers to complete an important production task (measured in seconds) is too erratic and adversely affects expected profits. The supervisor proceeds by randomly sampling 5 individuals per hour for a period of 10 hours. The sample mean and range for each hour are listed below.

She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds, respectively.

One of the morals of the red bead experiment is that variation is part of any process.

A factory supervisor is concerned that the time it takes workers to complete an important production task (measured in seconds) is too erratic and adversely affects expected profits. The supervisor proceeds by randomly sampling 5 individuals per hour for a period of 10 hours. The sample mean and range for each hour are listed below.

She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds, respectively.

One of the morals of the red bead experiment is that variation is part of any process.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

53

TABLE 14-4

A factory supervisor is concerned that the time it takes workers to complete an important production task (measured in seconds) is too erratic and adversely affects expected profits. The supervisor proceeds by randomly sampling 5 individuals per hour for a period of 10 hours. The sample mean and range for each hour are listed below.

She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds, respectively.

The p chart is a control chart used for monitoring the proportion of items that meet given specifications.

A factory supervisor is concerned that the time it takes workers to complete an important production task (measured in seconds) is too erratic and adversely affects expected profits. The supervisor proceeds by randomly sampling 5 individuals per hour for a period of 10 hours. The sample mean and range for each hour are listed below.

She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds, respectively.

The p chart is a control chart used for monitoring the proportion of items that meet given specifications.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

54

TABLE 14-5

A manufacturer of computer disks took samples of 240 disks on 15 consecutive days. The number of disks with bad sectors was determined for each of these samples. The results are in the table that follows.

Referring to Table 14-5, construct a p control chart for these data.

A manufacturer of computer disks took samples of 240 disks on 15 consecutive days. The number of disks with bad sectors was determined for each of these samples. The results are in the table that follows.

Referring to Table 14-5, construct a p control chart for these data.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

55

TABLE 14-5

A manufacturer of computer disks took samples of 240 disks on 15 consecutive days. The number of disks with bad sectors was determined for each of these samples. The results are in the table that follows.

Referring to Table 14-5, the best estimate of the mean proportion of disks with bad sectors is ________.

A manufacturer of computer disks took samples of 240 disks on 15 consecutive days. The number of disks with bad sectors was determined for each of these samples. The results are in the table that follows.

Referring to Table 14-5, the best estimate of the mean proportion of disks with bad sectors is ________.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

56

TABLE 14-6

The maker of a packaged candy wants to evaluate the quality of her production process. On each of 16 consecutive days, she samples 600 bags of candy and determines the number in each day's sample that she considers to be of poor quality. The data that she developed follow.

Referring to Table 14-6, the estimate of the proportion of poor quality bags of candy is ________.

The maker of a packaged candy wants to evaluate the quality of her production process. On each of 16 consecutive days, she samples 600 bags of candy and determines the number in each day's sample that she considers to be of poor quality. The data that she developed follow.

Referring to Table 14-6, the estimate of the proportion of poor quality bags of candy is ________.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

57

TABLE 14-6

The maker of a packaged candy wants to evaluate the quality of her production process. On each of 16 consecutive days, she samples 600 bags of candy and determines the number in each day's sample that she considers to be of poor quality. The data that she developed follow.

Referring to Table 14-6, a p control chart is to be constructed for these data. The center line for the chart should be located at ________.

The maker of a packaged candy wants to evaluate the quality of her production process. On each of 16 consecutive days, she samples 600 bags of candy and determines the number in each day's sample that she considers to be of poor quality. The data that she developed follow.

Referring to Table 14-6, a p control chart is to be constructed for these data. The center line for the chart should be located at ________.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

58

TABLE 14-4

A factory supervisor is concerned that the time it takes workers to complete an important production task (measured in seconds) is too erratic and adversely affects expected profits. The supervisor proceeds by randomly sampling 5 individuals per hour for a period of 10 hours. The sample mean and range for each hour are listed below.

She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds, respectively.

The R chart is a control chart used to monitor a process mean.

A factory supervisor is concerned that the time it takes workers to complete an important production task (measured in seconds) is too erratic and adversely affects expected profits. The supervisor proceeds by randomly sampling 5 individuals per hour for a period of 10 hours. The sample mean and range for each hour are listed below.

She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds, respectively.

The R chart is a control chart used to monitor a process mean.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

59

________ causes of variation are correctable without modifying the system.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

60

TABLE 14-6

The maker of a packaged candy wants to evaluate the quality of her production process. On each of 16 consecutive days, she samples 600 bags of candy and determines the number in each day's sample that she considers to be of poor quality. The data that she developed follow.

Referring to Table 14-6, a p control chart is to be constructed for these data. The lower control limit is ________, while the upper control limit is ________.

The maker of a packaged candy wants to evaluate the quality of her production process. On each of 16 consecutive days, she samples 600 bags of candy and determines the number in each day's sample that she considers to be of poor quality. The data that she developed follow.

Referring to Table 14-6, a p control chart is to be constructed for these data. The lower control limit is ________, while the upper control limit is ________.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

61

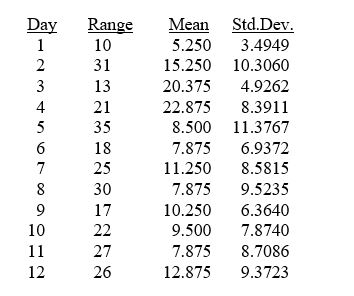

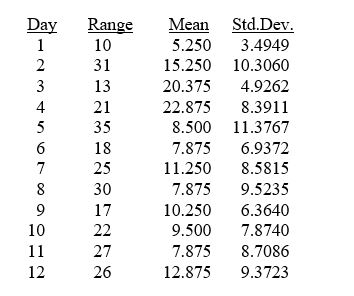

TABLE 14-8

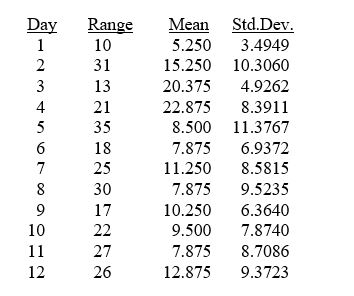

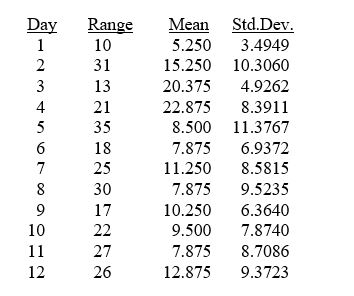

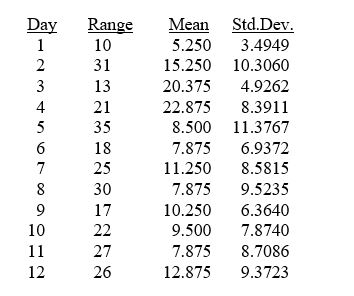

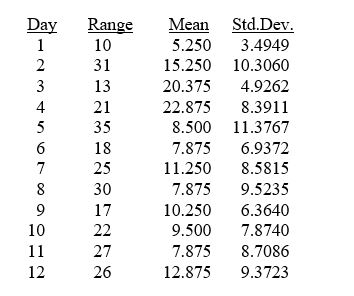

Recently, a university switched to a new type of computer-based registration. The registrar is concerned with the amount of time students are spending on the computer registering under the new system. She decides to randomly select 8 students on each of the 12 days of the registration and determine the time each spends on the computer registering. The range, mean, and standard deviation of the times required to register are in the table that follows.

Referring to Table 14-8, an R chart is to be constructed for the time required to register. The upper control limit for this data set is ________.

Recently, a university switched to a new type of computer-based registration. The registrar is concerned with the amount of time students are spending on the computer registering under the new system. She decides to randomly select 8 students on each of the 12 days of the registration and determine the time each spends on the computer registering. The range, mean, and standard deviation of the times required to register are in the table that follows.

Referring to Table 14-8, an R chart is to be constructed for the time required to register. The upper control limit for this data set is ________.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

62

TABLE 14-7

A supplier of silicone sheets for producers of computer chips wants to evaluate her manufacturing process. She takes samples of size 5 from each day's output and counts the number of blemishes on each silicone sheet. The results from 20 days of such evaluations are presented below.

She also decides that the upper specification limit is 10 blemishes.

Referring to Table 14-7, based on the R chart, it appears that the process is out of control.

A supplier of silicone sheets for producers of computer chips wants to evaluate her manufacturing process. She takes samples of size 5 from each day's output and counts the number of blemishes on each silicone sheet. The results from 20 days of such evaluations are presented below.

She also decides that the upper specification limit is 10 blemishes.

Referring to Table 14-7, based on the R chart, it appears that the process is out of control.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

63

TABLE 14-7

A supplier of silicone sheets for producers of computer chips wants to evaluate her manufacturing process. She takes samples of size 5 from each day's output and counts the number of blemishes on each silicone sheet. The results from 20 days of such evaluations are presented below.

She also decides that the upper specification limit is 10 blemishes.

Referring to Table 14-7, an R chart is to be constructed for the number of blemishes. The lower control limit for this data set is ________.

A supplier of silicone sheets for producers of computer chips wants to evaluate her manufacturing process. She takes samples of size 5 from each day's output and counts the number of blemishes on each silicone sheet. The results from 20 days of such evaluations are presented below.

She also decides that the upper specification limit is 10 blemishes.

Referring to Table 14-7, an R chart is to be constructed for the number of blemishes. The lower control limit for this data set is ________.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

64

TABLE 14-8

Recently, a university switched to a new type of computer-based registration. The registrar is concerned with the amount of time students are spending on the computer registering under the new system. She decides to randomly select 8 students on each of the 12 days of the registration and determine the time each spends on the computer registering. The range, mean, and standard deviation of the times required to register are in the table that follows.

Referring to Table 14-8, an R chart is to be constructed for the time required to register. The center line of this R chart is located at ________.

Recently, a university switched to a new type of computer-based registration. The registrar is concerned with the amount of time students are spending on the computer registering under the new system. She decides to randomly select 8 students on each of the 12 days of the registration and determine the time each spends on the computer registering. The range, mean, and standard deviation of the times required to register are in the table that follows.

Referring to Table 14-8, an R chart is to be constructed for the time required to register. The center line of this R chart is located at ________.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

65

TABLE 14-7

A supplier of silicone sheets for producers of computer chips wants to evaluate her manufacturing process. She takes samples of size 5 from each day's output and counts the number of blemishes on each silicone sheet. The results from 20 days of such evaluations are presented below.

She also decides that the upper specification limit is 10 blemishes.

Referring to Table 14-7, an R chart is to be constructed for the number of blemishes. One way to create the upper control limit involves multiplying the mean of the sample ranges by D₄. For this data set, the value of D₄ is ________.

A supplier of silicone sheets for producers of computer chips wants to evaluate her manufacturing process. She takes samples of size 5 from each day's output and counts the number of blemishes on each silicone sheet. The results from 20 days of such evaluations are presented below.

She also decides that the upper specification limit is 10 blemishes.

Referring to Table 14-7, an R chart is to be constructed for the number of blemishes. One way to create the upper control limit involves multiplying the mean of the sample ranges by D₄. For this data set, the value of D₄ is ________.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

66

TABLE 14-8

Recently, a university switched to a new type of computer-based registration. The registrar is concerned with the amount of time students are spending on the computer registering under the new system. She decides to randomly select 8 students on each of the 12 days of the registration and determine the time each spends on the computer registering. The range, mean, and standard deviation of the times required to register are in the table that follows.

Referring to Table 14-8, construct an R chart for the time required to register.

Recently, a university switched to a new type of computer-based registration. The registrar is concerned with the amount of time students are spending on the computer registering under the new system. She decides to randomly select 8 students on each of the 12 days of the registration and determine the time each spends on the computer registering. The range, mean, and standard deviation of the times required to register are in the table that follows.

Referring to Table 14-8, construct an R chart for the time required to register.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

67

TABLE 14-8

Recently, a university switched to a new type of computer-based registration. The registrar is concerned with the amount of time students are spending on the computer registering under the new system. She decides to randomly select 8 students on each of the 12 days of the registration and determine the time each spends on the computer registering. The range, mean, and standard deviation of the times required to register are in the table that follows.

Referring to Table 14-8, an R chart is to be constructed for the time required to register. The lower control limit for this data set is ________.

Recently, a university switched to a new type of computer-based registration. The registrar is concerned with the amount of time students are spending on the computer registering under the new system. She decides to randomly select 8 students on each of the 12 days of the registration and determine the time each spends on the computer registering. The range, mean, and standard deviation of the times required to register are in the table that follows.

Referring to Table 14-8, an R chart is to be constructed for the time required to register. The lower control limit for this data set is ________.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

68

TABLE 14-8

Recently, a university switched to a new type of computer-based registration. The registrar is concerned with the amount of time students are spending on the computer registering under the new system. She decides to randomly select 8 students on each of the 12 days of the registration and determine the time each spends on the computer registering. The range, mean, and standard deviation of the times required to register are in the table that follows.

Referring to Table 14-8, an R chart is to be constructed for the time required to register. One way to create the lower control limit involves multiplying the mean of the sample ranges by D₃. For this data set, the value of D₃ is ________.

Recently, a university switched to a new type of computer-based registration. The registrar is concerned with the amount of time students are spending on the computer registering under the new system. She decides to randomly select 8 students on each of the 12 days of the registration and determine the time each spends on the computer registering. The range, mean, and standard deviation of the times required to register are in the table that follows.

Referring to Table 14-8, an R chart is to be constructed for the time required to register. One way to create the lower control limit involves multiplying the mean of the sample ranges by D₃. For this data set, the value of D₃ is ________.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 107 في هذه المجموعة.

فتح الحزمة

k this deck

69

TABLE 14-7

A supplier of silicone sheets for producers of computer chips wants to evaluate her manufacturing process. She takes samples of size 5 from each day's output and counts the number of blemishes on each silicone sheet. The results from 20 days of such evaluations are presented below.

She also decides that the upper specification limit is 10 blemishes.

Referring to Table 14-7, based on the chart for the number of blemishes, it appears that the process is out of control.

chart for the number of blemishes, it appears that the process is out of control.

A supplier of silicone sheets for producers of computer chips wants to evaluate her manufacturing process. She takes samples of size 5 from each day's output and counts the number of blemishes on each silicone sheet. The results from 20 days of such evaluations are presented below.

She also decides that the upper specification limit is 10 blemishes.

Referring to Table 14-7, based on the

chart for the number of blemishes, it appears that the process is out of control.