Deck 6: Managing Flow Variability: Process Control and Capability

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

فتح الحزمة

قم بالتسجيل لفتح البطاقات في هذه المجموعة!

Unlock Deck

Unlock Deck

1/6

العب

ملء الشاشة (f)

Deck 6: Managing Flow Variability: Process Control and Capability

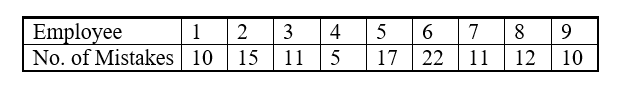

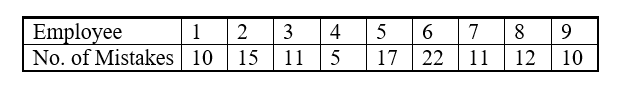

1

You are a manager with nine employees reporting directly to you. (You have full span of control.) All nine employees have essentially the same responsibilities. They all have numerous opportunities to make mistakes (of various types) in their jobs, but only a small chance of making any one particular mistake at any one time. In the past year you have recorded the following number of mistakes for each employee. Assume that all mistakes are equally critical, so that you cannot distinguish between employees based on the type of mistake they make.  It is time for evaluations and merit raise recommendations. Suggest an approach (you do not have to show any computations) to decide who to reward and who to penalize? Assume that the total number of transactions performed by each employee are the same during the year.

It is time for evaluations and merit raise recommendations. Suggest an approach (you do not have to show any computations) to decide who to reward and who to penalize? Assume that the total number of transactions performed by each employee are the same during the year.

It is time for evaluations and merit raise recommendations. Suggest an approach (you do not have to show any computations) to decide who to reward and who to penalize? Assume that the total number of transactions performed by each employee are the same during the year.

It is time for evaluations and merit raise recommendations. Suggest an approach (you do not have to show any computations) to decide who to reward and who to penalize? Assume that the total number of transactions performed by each employee are the same during the year.You should construct appropriate control limits based on the data available. For example, with this data, assuming Poisson distribution of errors, mean = variance = 12.55. So control limits are: 12.55 + 3 Sqrt (12.55) = (1.92, 23.18) Employees with error rates above the upper control limit or below the lower control limit would be asked for abnormal causes of variation. Effort should be made to eliminate assignable errors above the UCL and replicate assignable errors below the LCL. All employees with error rates within control limits should be treated equally. In this case, all employees seem to display normal variability, so take no action.In the long run, you should try to reduce the mean of 12.55 through better training, and mistake-proofing the process.

2

A customer wants delivery to be ensured between 10 am and 2 pm. Your truck leaves the factory at 4 am and the time taken to reach the customer is normally distributed with an average of 8 hrs and a standard deviation of 1 hr.

-What is the process capability ratio of the process?

A) 0.67

B) 0.50

C) 1.00

D) 2.00

E) None of the above

-What is the process capability ratio of the process?

A) 0.67

B) 0.50

C) 1.00

D) 2.00

E) None of the above

0.67

3

A customer wants delivery to be ensured between 10 am and 2 pm. Your truck leaves the factory at 4 am and the time taken to reach the customer is normally distributed with an average of 8 hrs and a standard deviation of 1 hr.

-What specific action(s) (in terms of mean and standard deviation targets to be achieved) would you take to improve the ability of the delivery process to be a 6-σ process (like Motorola)?

-What specific action(s) (in terms of mean and standard deviation targets to be achieved) would you take to improve the ability of the delivery process to be a 6-σ process (like Motorola)?

Target mean= Same as before

Target standard deviation = σ = 1/3 will yield Cp = 2, which corresponds to six sigma quality. To reduce the standard deviation, use interstate highways to avoid unforeseen traffic jams and lights. Get good, reliable trucks, reduce travel distance (which also affects the mean), improve driver training, etc.

Target standard deviation = σ = 1/3 will yield Cp = 2, which corresponds to six sigma quality. To reduce the standard deviation, use interstate highways to avoid unforeseen traffic jams and lights. Get good, reliable trucks, reduce travel distance (which also affects the mean), improve driver training, etc.

4

An assembly process has twenty successive stages, each with 3-σ capability. The company has come up with a new design that will require only ten assembly stages. The capability at each stage still remains 3-σ. The overall assembly process capability with the new design will be

• Higher than the original design.

• Same as the original design.

• Lower than the original design.

• Higher than the original design.

• Same as the original design.

• Lower than the original design.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 6 في هذه المجموعة.

فتح الحزمة

k this deck

5

A machine produces drive shafts. Manufacturing currently takes samples of 10 shafts every half an hour to check if the process is in control. Control limits have been set at ± 3 standard deviations of the sample means and are set at 10 ± 3×0.001 cm. A suggestion calls for control limits to be tightened to ± 2 standard deviations, i.e., 10± 2×0.001 cm. As a result the proportion of shafts produced that are defective (outside specification limits) will

A)Increase

B)Decrease

C)Remain unchanged

A)Increase

B)Decrease

C)Remain unchanged

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 6 في هذه المجموعة.

فتح الحزمة

k this deck

6

K-Log produces cereals that are sold in boxes labeled to contain 390 grams. If the cereal content is below 390 grams, K-Log may invite FDA scrutiny. Filling much more than 390 grams costs the company since it essentially means giving away more of the product. Accordingly, K-Log has set specification limits between 390 and 410 grams for the weight of cereal boxes. Currently the boxes are filled automatically by a filling machine and they have an average weight of 405 g with a standard deviation of 4 g. What process targets (in terms of mean and standard deviation of the filling process) are needed for the filling machine to have a six-σ capability?

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 6 في هذه المجموعة.

فتح الحزمة

k this deck