Deck 9: Evaluating and Improving Process Performance

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

فتح الحزمة

قم بالتسجيل لفتح البطاقات في هذه المجموعة!

Unlock Deck

Unlock Deck

1/49

العب

ملء الشاشة (f)

Deck 9: Evaluating and Improving Process Performance

1

Kaizen is focused on small incremental improvements in processes rather than infrequent large discrete changes.

True

2

Under the kaizen philosophy, line managers remain "in charge," setting standards and rewarding performance.

False

3

Deriving process improvements using a Western approach to management requires a total focus on eliminating waste from those processes.

False

4

The most significant component of the cost of quality is the cost of an external product failure.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 49 في هذه المجموعة.

فتح الحزمة

k this deck

5

In the design of a total quality management system, a natural trade-off will exist between prevention and detection costs.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 49 في هذه المجموعة.

فتح الحزمة

k this deck

6

Rework and scrap are common quality costs associated with external product failures.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 49 في هذه المجموعة.

فتح الحزمة

k this deck

7

Under the Taguchi loss function, the cost of not meeting specifications grows linearly with the size of the departure from standard.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 49 في هذه المجموعة.

فتح الحزمة

k this deck

8

Capacity utilization measurement based on theoretical capacity rather than normal capacity will provide a more useful signal to a decision to acquire additional capacity.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 49 في هذه المجموعة.

فتح الحزمة

k this deck

9

Practical capacity is determined by allowing for downtime due to unexpected machine breakdowns and/or abnormal process variations.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 49 في هذه المجموعة.

فتح الحزمة

k this deck

10

The budgeted waste variance results from below normal levels of demand for the output of the process.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 49 في هذه المجموعة.

فتح الحزمة

k this deck

11

Rate-based waste could be improved by reducing downtime due to normal foreseeable machine maintenance.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 49 في هذه المجموعة.

فتح الحزمة

k this deck

12

If budgeted capacity exceeds the actual capacity used, there will be an unfavorable efficiency waste variance.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 49 في هذه المجموعة.

فتح الحزمة

k this deck

13

A capacity cost management system can only be applied to processes that possess a time-linked measure of process capability.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 49 في هذه المجموعة.

فتح الحزمة

k this deck

14

The ratchet effect refers to resetting goals higher whenever an existing goal is met.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 49 في هذه المجموعة.

فتح الحزمة

k this deck

15

Gain-sharing refers to an intrinsic incentive system based on nonfinancial rewards.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 49 في هذه المجموعة.

فتح الحزمة

k this deck

16

Responsibility for recognizing and implementing process improvements under the kaizen philosophy of continuous improvement rests with:

A) Line managers.

B) Self-directed worker teams.

C) Upper-level management.

D) The corporate board of directors.

A) Line managers.

B) Self-directed worker teams.

C) Upper-level management.

D) The corporate board of directors.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 49 في هذه المجموعة.

فتح الحزمة

k this deck

17

Improvement focused on small incremental changes made as a result of ongoing efforts is characteristic of:

A) Maintenance.

B) Innovation.

C) Kaizen.

D) Management by exception.

A) Maintenance.

B) Innovation.

C) Kaizen.

D) Management by exception.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 49 في هذه المجموعة.

فتح الحزمة

k this deck

18

The Japanese term "muda" may be best described as:

A) Managing to make labor more productive.

B) Process improvements made through the elimination of wasteful activities and operations.

C) Maximizing a product's value proposition.

D) Pursuit of a zero-defects policy.

A) Managing to make labor more productive.

B) Process improvements made through the elimination of wasteful activities and operations.

C) Maximizing a product's value proposition.

D) Pursuit of a zero-defects policy.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 49 في هذه المجموعة.

فتح الحزمة

k this deck

19

Which of the items listed below are forms muda can take?

A) Overproduction.

B) Excess inventory.

C) Waiting.

D) All of the above are forms of muda.

A) Overproduction.

B) Excess inventory.

C) Waiting.

D) All of the above are forms of muda.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 49 في هذه المجموعة.

فتح الحزمة

k this deck

20

In addition to the absence of problems and deficiencies, product quality may be defined in terms of:

A) Product attributes valued by the customer resulting in a competitive advantage.

B) Minimal external product failures.

C) Minimal prevention costs.

D) Minimal detection costs.

A) Product attributes valued by the customer resulting in a competitive advantage.

B) Minimal external product failures.

C) Minimal prevention costs.

D) Minimal detection costs.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 49 في هذه المجموعة.

فتح الحزمة

k this deck

21

In a total quality management environment, the best system for achieving quality is:

A) Detection.

B) Product inspection.

C) Prevention.

D) Customer support.

A) Detection.

B) Product inspection.

C) Prevention.

D) Customer support.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 49 في هذه المجموعة.

فتح الحزمة

k this deck

22

EDD, Inc., produces state-of-the-art communication devices for military applications. Each year, the company incurs significant expense to rework completed units that fail product tests. These expenditures are an example of:

A) Prevention costs.

B) Detection costs.

C) Internal failure costs.

D) External failure costs.

A) Prevention costs.

B) Detection costs.

C) Internal failure costs.

D) External failure costs.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 49 في هذه المجموعة.

فتح الحزمة

k this deck

23

Many years ago, Honda Motor Car Company designed an automatic transmission that could only be assembled and installed in a vehicle in one way. Any departures from the design would prevent a worker from completing installation. This design led to a zero initial failure rate for the transmission. The investments in engineering costs to design this transmission best illustrate:

A) Prevention cost.

B) Detection cost.

C) Internal failure cost.

D) External failure cost.

A) Prevention cost.

B) Detection cost.

C) Internal failure cost.

D) External failure cost.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 49 في هذه المجموعة.

فتح الحزمة

k this deck

24

When measuring the cost of quality, the cost of inspecting incoming raw materials is a(n):

A) Prevention cost.

B) Appraisal cost.

C) Internal failure cost.

D) External failure cost.

A) Prevention cost.

B) Appraisal cost.

C) Internal failure cost.

D) External failure cost.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 49 في هذه المجموعة.

فتح الحزمة

k this deck

25

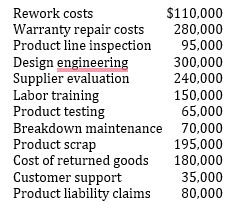

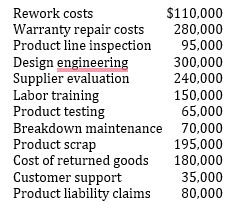

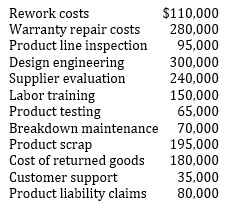

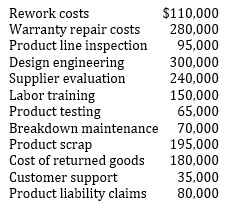

Leese Inc. has the following quality financial data for its most recent fiscal year.

The total amount of prevention costs that should be reported in a cost of quality report for the year is:

The total amount of prevention costs that should be reported in a cost of quality report for the year is:

A) $390,000.

B) $450,000.

C) $690,000.

D) $755,000.

The total amount of prevention costs that should be reported in a cost of quality report for the year is:

The total amount of prevention costs that should be reported in a cost of quality report for the year is:A) $390,000.

B) $450,000.

C) $690,000.

D) $755,000.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 49 في هذه المجموعة.

فتح الحزمة

k this deck

26

In measuring the cost of quality, which one of the following is considered an appraisal cost?

A) Rework cost.

B) Product testing cost.

C) Warranty claims cost.

D) Equipment maintenance cost.

A) Rework cost.

B) Product testing cost.

C) Warranty claims cost.

D) Equipment maintenance cost.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 49 في هذه المجموعة.

فتح الحزمة

k this deck

27

Style Retouche, Inc., produces compact paint pens used to repair small nicks in exterior automotive paint finishes. If the machinery that fills the pens is not completely cleaned between production runs of different colors, the resulting paint will not match the original color intended. Style Retouche estimates that the cost of a mismatched pen that reaches a customer is $40. The company's target for the residual content of the previous color remaining in the machinery is 0.00 parts per million. Using the Taguchi loss function, how does the quality loss for an actual residual content of 0.01 parts per million compare to the quality loss for an actual content of 0.02 parts per million?

A) The quality loss at 0.02 parts per million is twice as large as the quality loss at 0.01 parts per million.

B) The quality loss at 0.02 parts per million is equal to the quality loss at 0.01 parts per million.

C) The quality loss at 0.02 parts per million is four times as large as the quality loss at 0.01 parts per million.

D) The quality loss at 0.02 parts per million is 40 times as large as the quality loss at 0.01 parts per million.

A) The quality loss at 0.02 parts per million is twice as large as the quality loss at 0.01 parts per million.

B) The quality loss at 0.02 parts per million is equal to the quality loss at 0.01 parts per million.

C) The quality loss at 0.02 parts per million is four times as large as the quality loss at 0.01 parts per million.

D) The quality loss at 0.02 parts per million is 40 times as large as the quality loss at 0.01 parts per million.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 49 في هذه المجموعة.

فتح الحزمة

k this deck

28

A key benefit of the Malcolm Baldrige Award for Performance Excellence program is:

A) The increased availability of best-in-practice firms to support benchmarking studies.

B) Its mandate to issue publicly available cost of quality reports.

C) Its requirement that participants adopt the kaizen philosophy of continuous improvement.

D) Widespread adoption of the Taguchi loss function.

A) The increased availability of best-in-practice firms to support benchmarking studies.

B) Its mandate to issue publicly available cost of quality reports.

C) Its requirement that participants adopt the kaizen philosophy of continuous improvement.

D) Widespread adoption of the Taguchi loss function.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 49 في هذه المجموعة.

فتح الحزمة

k this deck

29

A "trended average actual cost," where cost moves across time, and as one observation is added to the data set, the oldest observation is eliminated, is an illustration of:

A) A zero-based average cost.

B) A weighted average cost.

C) A rolling average cost.

D) A geometric average cost.

A) A zero-based average cost.

B) A weighted average cost.

C) A rolling average cost.

D) A geometric average cost.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 49 في هذه المجموعة.

فتح الحزمة

k this deck

30

A scrapyard operates a machine that crushes vehicles. The machine is capable of crushing 12 vehicles per hour. If the machine crushed 2,016 vehicles in the past seven days, it reached its:

A) Weekly theoretical capacity.

B) Weekly budgeted capacity.

C) Weekly practical capacity.

D) Weekly normal capacity.

A) Weekly theoretical capacity.

B) Weekly budgeted capacity.

C) Weekly practical capacity.

D) Weekly normal capacity.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 49 في هذه المجموعة.

فتح الحزمة

k this deck

31

Gnash Motor Cars, Inc., employs a robotic spray booth to paint automobile bodies in its Flintstone plant. The robotic spray booth is capable of painting five cars per hour. Thus, its weekly theoretical capacity is 840 cars. Company engineers have set the rated speed of the spray booth at four cars per hour to allow for unavoidable downtime for maintenance and process irregularities.

-The output sacrificed based on the assumption that this spray booth can operate effectively 80% of the time is termed:

A) Budgeted waste.

B) Efficiency waste.

C) Rate-based waste.

D) Management policy waste.

-The output sacrificed based on the assumption that this spray booth can operate effectively 80% of the time is termed:

A) Budgeted waste.

B) Efficiency waste.

C) Rate-based waste.

D) Management policy waste.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 49 في هذه المجموعة.

فتح الحزمة

k this deck

32

Gnash Motor Cars, Inc., employs a robotic spray booth to paint automobile bodies in its Flintstone plant. The robotic spray booth is capable of painting five cars per hour. Thus, its weekly theoretical capacity is 840 cars. Company engineers have set the rated speed of the spray booth at four cars per hour to allow for unavoidable downtime for maintenance and process irregularities.

- Management intends to operate the spray booth for two eight-hour shifts, five days per week. The output sacrificed based on the planned utilization of this spray booth is termed:

A) Budgeted waste.

B) Efficiency waste.

C) Rate-based waste.

D) Management policy waste.

- Management intends to operate the spray booth for two eight-hour shifts, five days per week. The output sacrificed based on the planned utilization of this spray booth is termed:

A) Budgeted waste.

B) Efficiency waste.

C) Rate-based waste.

D) Management policy waste.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 49 في هذه المجموعة.

فتح الحزمة

k this deck

33

Kecks Bottling Company produces 2-liter soda bottles in its Somerset plant using an injection-molding machine that has a theoretical capacity of 60,480 bottles per week. For the most recently completed week, the company's capacity cost management system reported an efficiency waste variance of 3,144 bottles. This variance indicates that:

A) Demand for 2-liter bottles was less than normal.

B) All downtime for maintenance and process irregularities was within the unavoidable range.

C) The company experienced unexpected downtime on the machine for maintenance or other process irregularities.

D) The injection-molding machine consumed more than the standard quantity of raw material allowed for the level of production achieved.

A) Demand for 2-liter bottles was less than normal.

B) All downtime for maintenance and process irregularities was within the unavoidable range.

C) The company experienced unexpected downtime on the machine for maintenance or other process irregularities.

D) The injection-molding machine consumed more than the standard quantity of raw material allowed for the level of production achieved.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 49 في هذه المجموعة.

فتح الحزمة

k this deck

34

Kecks Bottling Company produces 2-liter soda bottles in its Somerset plant using an injection-molding machine that has a theoretical capacity of 60,480 bottles per week. For the most recently completed week, the company's capacity cost management system reported an efficiency waste variance of 3,144 bottles. This variance indicates that:

A) Practical capacity exceeded theoretical capacity for the week.

B) Actual capacity used fell short of budgeted capacity.

C) Budgeted capacity exceeded normal capacity.

D) Normal capacity exceeded practical capacity.

A) Practical capacity exceeded theoretical capacity for the week.

B) Actual capacity used fell short of budgeted capacity.

C) Budgeted capacity exceeded normal capacity.

D) Normal capacity exceeded practical capacity.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 49 في هذه المجموعة.

فتح الحزمة

k this deck

35

Kecks Bottling Company produces 2-liter soda bottles in its Somerset plant using an injection-molding machine that has a theoretical capacity of 60,480 bottles per week. For the most recently completed week, the company's capacity cost management system reported actual production of 15,144 bottles. This represented 72% utilization of the machine's normal capacity of 21,168 bottles. Based on this rate of capacity utilization, line managers are advocating for the acquisition of an additional injection-molding machine. What measure of capacity utilization would provide a better signal of the need for an additional machine?

A) Capacity utilization based on theoretical capacity.

B) Capacity utilization based on market demand.

C) Capacity utilization based on normal capacity adjusted for the efficiency waste variance.

D) Capacity utilization based on productive capacity adjusted for idle capacity.

A) Capacity utilization based on theoretical capacity.

B) Capacity utilization based on market demand.

C) Capacity utilization based on normal capacity adjusted for the efficiency waste variance.

D) Capacity utilization based on productive capacity adjusted for idle capacity.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 49 في هذه المجموعة.

فتح الحزمة

k this deck

36

A capacity cost management system and capacity variance analysis can only be used to support continuous improvement when:

A) The kaizen philosophy is entrenched throughout the organization.

B) The process has a reliable, repetitive, time-linked measure of process capability.

C) The organization is committed to a total quality management system.

D) An activity-based costing system is in place.

A) The kaizen philosophy is entrenched throughout the organization.

B) The process has a reliable, repetitive, time-linked measure of process capability.

C) The organization is committed to a total quality management system.

D) An activity-based costing system is in place.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 49 في هذه المجموعة.

فتح الحزمة

k this deck

37

If a process is people-paced and lacks a reliable time-linked measure of capability, then the appropriate tool for improving capacity baseline measures is:

A) Standard cost variance analysis.

B) Flexible budgeting.

C) Activity-based management.

D) Just-in-time production.

A) Standard cost variance analysis.

B) Flexible budgeting.

C) Activity-based management.

D) Just-in-time production.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 49 في هذه المجموعة.

فتح الحزمة

k this deck

38

The amount of time it takes for manufacturing to produce a given product from the time the order is released to production to finished goods is:

A) The on-time delivery to commit.

B) The manufacturing cycle time.

C) The time to make changeovers.

D) The on-time shipping performance.

A) The on-time delivery to commit.

B) The manufacturing cycle time.

C) The time to make changeovers.

D) The on-time shipping performance.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 49 في هذه المجموعة.

فتح الحزمة

k this deck

39

Windsor Company is a distributor of California wines. In a recent week, the company received 400 orders with an average of five lines per order. During the week, 368 of the orders were shipped on time. The company back-orders on average 1.75 out of every five items ordered by a customer.

- What percentage of customers fails to receive a complete order the first time?

A) 35%

B) 8%

C) 92%

D) 65%

- What percentage of customers fails to receive a complete order the first time?

A) 35%

B) 8%

C) 92%

D) 65%

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 49 في هذه المجموعة.

فتح الحزمة

k this deck

40

Windsor Company is a distributor of California wines. In a recent week, the company received 400 orders with an average of five lines per order. During the week, 368 of the orders were shipped on time. The company back-orders on average 1.75 out of every five items ordered by a customer.

-What is the company's on-time shipment percentage?

A) 65%

B) 59.8%

C) 35%

D) 92%

-What is the company's on-time shipment percentage?

A) 65%

B) 59.8%

C) 35%

D) 92%

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 49 في هذه المجموعة.

فتح الحزمة

k this deck

41

The percentage of time that manufacturing delivers a completed product on the schedule that was promised to customers is:

A) On-time delivery to commit.

B) Manufacturing cycle time.

C) On-time shipping performance.

D) Theoretical delivery capacity.

A) On-time delivery to commit.

B) Manufacturing cycle time.

C) On-time shipping performance.

D) Theoretical delivery capacity.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 49 في هذه المجموعة.

فتح الحزمة

k this deck

42

The use of rolling standards to monitor and manage performance and build in continuous improvement is commonly referred to as:

A) The ratchet effect.

B) Responsibility accounting.

C) Zero-based budgeting.

D) Kaizen.

A) The ratchet effect.

B) Responsibility accounting.

C) Zero-based budgeting.

D) Kaizen.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 49 في هذه المجموعة.

فتح الحزمة

k this deck

43

Which of the following conditions have been shown necessary for a ratchet effect to operate in an incentive system?

A) There must be an entrenched minimum standard of performance.

B) A principle encouraging innovation must be implemented.

C) The minimum standard must go up or down with each innovation.

D) All of the above are necessary to the operation of a ratchet effect.

A) There must be an entrenched minimum standard of performance.

B) A principle encouraging innovation must be implemented.

C) The minimum standard must go up or down with each innovation.

D) All of the above are necessary to the operation of a ratchet effect.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 49 في هذه المجموعة.

فتح الحزمة

k this deck

44

An incentive system that gives a portion of the profit resulting from process improvements to throughput, quality, cycle time, etc., to the workforce is called:

A) Intrinsic motivation.

B) Gain-sharing.

C) A negative ratchet.

D) A share-based compensation system.

A) Intrinsic motivation.

B) Gain-sharing.

C) A negative ratchet.

D) A share-based compensation system.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 49 في هذه المجموعة.

فتح الحزمة

k this deck

45

Some observers have described the reliance on team structures to achieve process improvements as clan-based control. The most important aspect of clan forms of control to process management is:

A) Their dependence on trust among clan members.

B) Reliance on incentive systems.

C) The dominance of upper-level management.

D) The organization of work into a cellular structure.

A) Their dependence on trust among clan members.

B) Reliance on incentive systems.

C) The dominance of upper-level management.

D) The organization of work into a cellular structure.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 49 في هذه المجموعة.

فتح الحزمة

k this deck

46

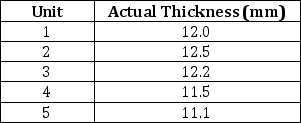

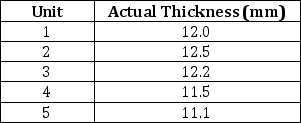

Bendix Company produces replacement brake pads for automobiles. The thickness of the abrasive material on the pads is critical to their performance. If the pads are too thin, they will wear prematurely, and if they are too thick, they will fit improperly resulting in excess brake noise and vibration. Bendix has determined that its costs are $500 when a nonconforming pad is installed in a customer's vehicle. The target thickness for the pads is 12 mm. It test-measures the thickness of the abrasive on a sample of five pads; the results are given in the table below.

Required:

Required:

Compute the total quality loss for Bendix using the Taguchi loss function.

Required:

Required:Compute the total quality loss for Bendix using the Taguchi loss function.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 49 في هذه المجموعة.

فتح الحزمة

k this deck

47

Moroccan Ceiling Fans, Inc., employs an automated process to package its fans. One machine is used to form the cardboard boxes into which the fans and parts are placed. The manufacturer of the machine specifies that it is capable of constructing six cardboard boxes per minute. The machine is rated by Moroccan's engineers to run four boxes per minute, due to practical constraints. Output over the past three years has been 9,200 boxes per week, 9,100 boxes per week, and 9,300 boxes per week. Considering current demand for ceiling fans, the machine is budgeted to produce 8,800 boxes per week this year. The machine is operated five days per week for a single eight-hour shift. During a recently completed week, the machine's actual output was 7,200 boxes.

Required:

a) Prepare a capacity utilization variance analysis for Moroccan Ceiling Fans, Inc.

b) The manager of the packaging department has observed that once the efficiency waste variance is corrected, the machine will be operating at nearly 92% capacity. She recommends acquisition of a second machine or replacing the current machine with one that has a larger capacity. Evaluate the packaging manager's concern based on measures of capacity utilization.

Required:

a) Prepare a capacity utilization variance analysis for Moroccan Ceiling Fans, Inc.

b) The manager of the packaging department has observed that once the efficiency waste variance is corrected, the machine will be operating at nearly 92% capacity. She recommends acquisition of a second machine or replacing the current machine with one that has a larger capacity. Evaluate the packaging manager's concern based on measures of capacity utilization.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 49 في هذه المجموعة.

فتح الحزمة

k this deck

48

Leese Inc. has the following cost of quality financial data for its most recent fiscal year.

Required:

Required:

Develop a cost of quality report for Leese, Inc. for the fiscal year. State your amounts in both dollars and percent of the total.

Required:

Required:Develop a cost of quality report for Leese, Inc. for the fiscal year. State your amounts in both dollars and percent of the total.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 49 في هذه المجموعة.

فتح الحزمة

k this deck

49

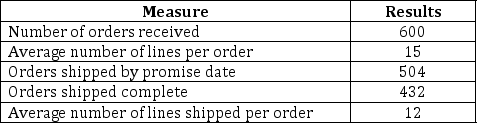

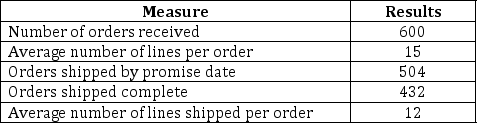

Hobby Express is a retail distributor of hobby and craft supplies. It commonly receives orders from customers specifying as many as 15 to 20 line items. Numerous customer complaints center on receiving orders that were not complete and being informed that several items were placed on back order. The company's shipping manager compiled the information below for delivery performance last week.

Required:

Required:

Develop several delivery metrics and comment on changes that need to be made to existing performance and why.

Required:

Required:Develop several delivery metrics and comment on changes that need to be made to existing performance and why.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 49 في هذه المجموعة.

فتح الحزمة

k this deck