Deck 13: Jitlean Production

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

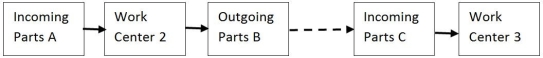

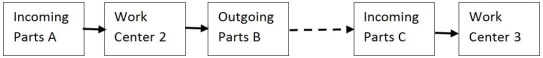

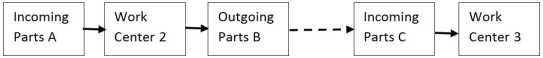

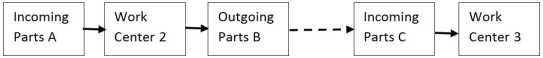

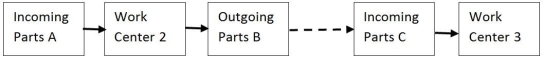

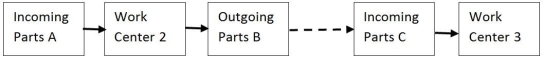

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

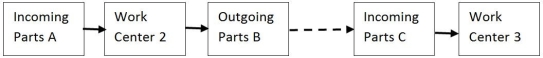

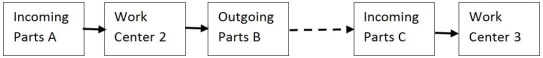

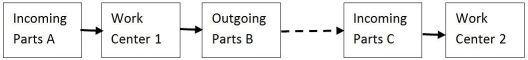

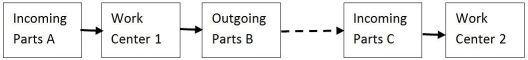

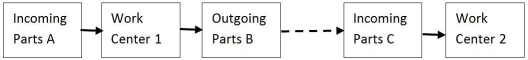

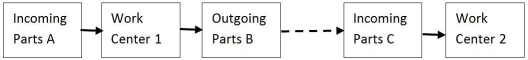

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

فتح الحزمة

قم بالتسجيل لفتح البطاقات في هذه المجموعة!

Unlock Deck

Unlock Deck

1/64

العب

ملء الشاشة (f)

Deck 13: Jitlean Production

1

The newest form of waste is underutilizing employees.

True

2

Describe any five of the wastes and their causes identified by the lean philosophy.

According to the lean perspective,waste,or muda,is any activity that does not add value to the good or service in the eyes of the consumer.There are eight commonly recognized ones,so answers will vary depending on which five are selected.

overproduction - caused by inflexible or unreliable processes that cause organizations to produce goods before they are required.

waiting - caused by inefficient layouts or an inability to match demand with output levels.

unnecessary transportation - always increasing costs and the risk of damage without adding value.

inappropriate process - using overly complex processes when simpler,more efficient ones would do.

unnecessary inventory - caused by uncertainty with regard to quality levels,delivery lead times,etc.

unnecessary/excess motion - caused by poorly designed processes.

defects - creating uncertainty in the process and robbing production capacity by creating products or services that require rework or must be scrapped.

underutilization of employees - caused by not utilizing the skills and decision-making capabilities of their employees.

overproduction - caused by inflexible or unreliable processes that cause organizations to produce goods before they are required.

waiting - caused by inefficient layouts or an inability to match demand with output levels.

unnecessary transportation - always increasing costs and the risk of damage without adding value.

inappropriate process - using overly complex processes when simpler,more efficient ones would do.

unnecessary inventory - caused by uncertainty with regard to quality levels,delivery lead times,etc.

unnecessary/excess motion - caused by poorly designed processes.

defects - creating uncertainty in the process and robbing production capacity by creating products or services that require rework or must be scrapped.

underutilization of employees - caused by not utilizing the skills and decision-making capabilities of their employees.

3

JIT or Lean can be used in:

A) repetitive production.

B) job shop production.

C) many service industries.

D) All of these settings are appropriate for JIT.

A) repetitive production.

B) job shop production.

C) many service industries.

D) All of these settings are appropriate for JIT.

D

4

Companies employing the Lean philosophy use only Kanban as a production control method.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

5

Just-in-time production is also referred to as ________.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

6

Which of the following is NOT an element of Lean production?

A) to have only the required inventory when needed

B) to increase queue lengths

C) to improve quality to zero defects

D) to reduce setup times

A) to have only the required inventory when needed

B) to increase queue lengths

C) to improve quality to zero defects

D) to reduce setup times

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

7

Lean thinking has received considerable attention in the last decade,but tools such as kanbans cannot be used in all production environments.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

8

Inflexible or unreliable processes cause organizations to produce goods before they are required; this is called:

A) excess motion.

B) inappropriate processes.

C) overproduction.

D) defects.

A) excess motion.

B) inappropriate processes.

C) overproduction.

D) defects.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

9

The delivery lead time was highly variable as was the quality of the product being shipped.These two factors combined to contribute to the waste of:

A) unnecessary transportation.

B) unnecessary inventory.

C) unnecessary motion.

D) waiting.

A) unnecessary transportation.

B) unnecessary inventory.

C) unnecessary motion.

D) waiting.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

10

Provide a definition by description of the Lean philosophy.Where can Lean be deployed?

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

11

Unnecessary transportation is waste according to the Lean philosophy.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

12

Any activity that does not add value to the good or service in the eyes of the consumer is ________.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

13

Since a Lean manufacturer has very little inventory,it is vital that all incoming parts receive a thorough inspection.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

14

The ability of a process to produce quality output is unknown and the time to ship the output to a customer is highly variable.The combination of these two factors will lead to the waste of waiting.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

15

The term just-in-time production is used synonymously with the term Lean production.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

16

The MBA recruiter had worked in one of several different positions at the university; student advisor,adjunct professor,even MBA director at a previous employer.Her sole responsibility as recruiter was attending MBA and job fairs in the area to talk to prospective students about the possibility of continuing their education.This illustrates the waste of:

A) unnecessary inventory.

B) overproduction.

C) unnecessary transportation.

D) underutilization of employees.

A) unnecessary inventory.

B) overproduction.

C) unnecessary transportation.

D) underutilization of employees.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

17

The just-in-time philosophy applies only to the production floor of a manufacturing company.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

18

Scrap or rework are examples of the lean waste recognized as:

A) defects.

B) inappropriate processing.

C) unnecessary motion.

D) waiting.

A) defects.

B) inappropriate processing.

C) unnecessary motion.

D) waiting.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

19

A reduction in inventory levels forces a company to address poor manufacturing practices.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

20

The receiving department accepts a shipment,confirms it matches the purchase order,and moves it to an area they call "deep storage." As the time approaches for the shipment to be used,they move it from deep storage to the week's holding pen,and on the day of use,it is transferred to the line near where it will fall into the product stream.When the worker needs it,she goes to where it is stored and brings it to her work station.This illustrates the waste of:

A) unnecessary inventory.

B) overproduction.

C) unnecessary transportation.

D) underutilization of employees.

A) unnecessary inventory.

B) overproduction.

C) unnecessary transportation.

D) underutilization of employees.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

21

The cards employed in a two-card kanban system are the production card and the move card.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

22

One recent development in Lean thinking is the combination of Lean and Six Sigma into Lean Six Sigma,which combines the rigor of statistical analysis and DMAIC approach with Lean's focus on waste reduction.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

23

What is the Lean perspective on inventory?

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

24

In the lean perspective on inventory,often when a process is running smoothly:

A) it is likely that workers are underutilized.

B) it is likely that there is too little inventory in the system.

C) it is likely that there is too much inventory in the system.

D) it is likely that workers are overutilized.

A) it is likely that workers are underutilized.

B) it is likely that there is too little inventory in the system.

C) it is likely that there is too much inventory in the system.

D) it is likely that workers are overutilized.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

25

A two-card kanban system is a planning tool that links production and movement of units at two work centers.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

26

Lean supply chain management focuses on eliminating waste:

A) in a firm's sourcing and logistics activities.

B) within a firm's internal operations.

C) in flows of information and money among supply chain partners.

D) in all of the above areas.

A) in a firm's sourcing and logistics activities.

B) within a firm's internal operations.

C) in flows of information and money among supply chain partners.

D) in all of the above areas.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

27

________ could result in workers from one company working to solve production issues for a company from which they purchase components.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

28

Recent developments in Lean thinking have combined these principles with Six Sigma and with supply chain management.Pick either one of these programs and describe its elements.Then provide an example from current business news of an operation or supply chain that has embraced these principles.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

29

The analogy of rocks in a river is often used when discussing Lean principles.In the analogy,the rocks represent ________ while the water represents ________.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

30

For a kanban system to work properly,demand rates must be relatively stable,and interruptions must be minimized.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

31

In the kanban formula,the letter T represents the time it takes to empty a box of parts through building product.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

32

A company has successfully implemented lean practices in their three station process.The stations are,in order,Station A,Station B,and Station C and product moves from A to B to C smoothly.One day,the equipment at Station B experiences catastrophic failure.What happens and what is the appropriate response for a lean-thinking company?

A) Continue producing at Station C and restore capacity at Station B.

B) Continue producing at Station A and restore capacity at Station B.

C) Continue producing at Station A and C and restore capacity at Station B.

D) Everything stops and attention is focused on restoring capacity at Station B.

A) Continue producing at Station C and restore capacity at Station B.

B) Continue producing at Station A and restore capacity at Station B.

C) Continue producing at Station A and C and restore capacity at Station B.

D) Everything stops and attention is focused on restoring capacity at Station B.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

33

A kanban can be:

A) a container.

B) a card.

C) a visual cue.

D) All of these can be kanbans.

A) a container.

B) a card.

C) a visual cue.

D) All of these can be kanbans.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

34

An increase in the safety factor results in an increase in the amount of inventory in a kanban system.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

35

Some companies have found it beneficial to combine the planning capabilities of kanban with the control capabilities of MRP.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

36

________ combines the focus on waste reduction with the discipline of define,measure,analyze,improve,and control.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

37

The forecast for next month is 200 units so the manufacturer gathers materials for this anticipated level of production activity.This is an example of pull production.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

38

In the water and rocks analogy for lean:

A) water represents problems.

B) water represents inventory.

C) rocks represent inventory.

D) water wears away rocks gradually just like continuous improvement programs improve quality.

A) water represents problems.

B) water represents inventory.

C) rocks represent inventory.

D) water wears away rocks gradually just like continuous improvement programs improve quality.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

39

A pull system is a production system in which actual downstream demand sets off a chain of events that pull material through various steps in the production process.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

40

The greater the demand,the more kanbans are needed.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

41

In a single-card kanban system:

A) the single card is the production card.

B) the empty container serves as the production card.

C) the single card is the move signal.

D) None of the above is correct in a single-card system.

A) the single card is the production card.

B) the empty container serves as the production card.

C) the single card is the move signal.

D) None of the above is correct in a single-card system.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

42

Liversuch Industries uses a kanban system to manage production of the J-15 subassembly.They have an hourly demand for 250 units and use containers that can hold 50 units each.It takes 90 minutes to fill and move a container of parts to the right place on the J-15 line that is currently rated at a 20% safety factor.How many production cards are needed?

A) 540

B) 100

C) 9

D) 1.5

A) 540

B) 100

C) 9

D) 1.5

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

43

Consider the adjacent work stations in this two card Kanban system.Work Center 3 has just pulled the Incoming Parts C box to their work station.What happens to the cards in the Incoming Parts C box and at the work station?

A) The move card at their station goes in the Incoming Parts C box and the production card is pulled from the Incoming Parts C box to signal the worker at Work Center 2 that there is a need to produce material.

B) The production card at the station is passed back to Work Center 2 as a signal to produce more material and the move card is left at Work Center 3 to signal that they are ready to accept materials when they are complete at Work Center 2.

C) The move card at their station goes in the box they will send downstream to Work Center 4 and the production card is placed at the Work Center 3 station while they are working on this batch of material.

D) The production card at their station goes in the Incoming Parts C box and the move card is pulled from the Incoming Parts C box to signal the worker at Work Center 2 that there is a need to move material.

A) The move card at their station goes in the Incoming Parts C box and the production card is pulled from the Incoming Parts C box to signal the worker at Work Center 2 that there is a need to produce material.

B) The production card at the station is passed back to Work Center 2 as a signal to produce more material and the move card is left at Work Center 3 to signal that they are ready to accept materials when they are complete at Work Center 2.

C) The move card at their station goes in the box they will send downstream to Work Center 4 and the production card is placed at the Work Center 3 station while they are working on this batch of material.

D) The production card at their station goes in the Incoming Parts C box and the move card is pulled from the Incoming Parts C box to signal the worker at Work Center 2 that there is a need to move material.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

44

Consider the adjacent work stations in this two card Kanban system.There is a production card located in the box labeled Outgoing Parts B.Work Center 3 pulls the parts from Work Center 2.Where does the production card go?

A) The production card remains in the same box.

B) The production card is placed at Work Center 3.

C) The production card is placed at Work Center 2.

D) The production card is placed in the box labeled Incoming Parts A.

A) The production card remains in the same box.

B) The production card is placed at Work Center 3.

C) The production card is placed at Work Center 2.

D) The production card is placed in the box labeled Incoming Parts A.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

45

Livernonions Industries uses a kanban system to manage production of the BR-549 subassembly.In an eight-hour day,they use 900 units and use containers that can hold 30 units each.It takes 120 minutes to fill and move a container of parts to the right place on the BR-549 line that is currently rated at a 15% safety factor.How many production hours of inventory are needed?

A) 18.4

B) 7.6

C) 4.3

D) 2.4

A) 18.4

B) 7.6

C) 4.3

D) 2.4

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

46

Under two-card kanban system rules,each box of raw material must have a(n)________,while each box of finished goods must have a(n)________.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

47

Livermore Industries uses a kanban system to manage production of the KR-9 subassembly.In a ten-hour day,they use 1500 units and use containers that can hold 50 units each.It takes 45 minutes to fill and move a container of parts to the right place on the KR-9 line that is currently rated at a 15% safety factor.How many production cards are needed?

A) 3

B) 26

C) 82

D) 155

A) 3

B) 26

C) 82

D) 155

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

48

Companies that use MRP and kanban together use the ________ of MRP and the ________ of kanban.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

49

A manufacturer waits to produce until they have an order from a customer.This type of production system is called ________.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

50

Olivia has had enough of the theoretical equations and rejects the higher math needed to calculate the number of kanbans for her system.One approach that some organizations take in lieu of the kanban equation is to:

A) start with one kanban and operate as fast as they can with the one, before adding more kanbans to bring them up to speed.

B) start with too many kanbans and gradually remove them until a problem arises.

C) fully load their system with inventory and produce until they cannot build product.

D) eliminate all inventory from the system and add material and parts until they can fill a customer order.

A) start with one kanban and operate as fast as they can with the one, before adding more kanbans to bring them up to speed.

B) start with too many kanbans and gradually remove them until a problem arises.

C) fully load their system with inventory and produce until they cannot build product.

D) eliminate all inventory from the system and add material and parts until they can fill a customer order.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

51

Consider the adjacent work stations in this two card Kanban system.There is a production card located:

A) in box A.

B) in box B.

C) at work center 1 and work center 2.

D) in box C.

A) in box A.

B) in box B.

C) at work center 1 and work center 2.

D) in box C.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

52

A(n)________ is a production control approach that uses containers,cards,or visual cues to control production and movement of goods throughout the supply chain.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

53

Consider the adjacent work stations in this two card Kanban system.Work Center 3 has just pulled the Incoming Parts C box to their work station.Plant manager Taichi Ohno grabs the microphone for the company PA system and announces that effective immediately,the company will switch to a one card system.Which of these actions is appropriate?

A) The production card will be discarded and the empty container will function as a production signal.

B) The move card will be discarded and the empty container will function as a move signal.

C) Both the move and production cards will be discarded in favor of a combined move/production card.

D) The production card will be discarded as production will be implied and the move cards will signal when items are needed downstream.

A) The production card will be discarded and the empty container will function as a production signal.

B) The move card will be discarded and the empty container will function as a move signal.

C) Both the move and production cards will be discarded in favor of a combined move/production card.

D) The production card will be discarded as production will be implied and the move cards will signal when items are needed downstream.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

54

When using MRP and kanban together:

A) the control capabilities of MRP are used instead of those from kanban.

B) the planning capabilities of kanban are used instead of those from MRP.

C) the demand rate should be variable in order to derive the greatest benefit from the MRP portion of the system.

D) the number of kanbans is recalculated from the MRP system's order changes throughout the horizon.

A) the control capabilities of MRP are used instead of those from kanban.

B) the planning capabilities of kanban are used instead of those from MRP.

C) the demand rate should be variable in order to derive the greatest benefit from the MRP portion of the system.

D) the number of kanbans is recalculated from the MRP system's order changes throughout the horizon.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

55

Consider the adjacent work stations in this two card Kanban system.There is a move card located:

A) in box A.

B) in box B.

C) both in box A and box C.

D) in box C.

A) in box A.

B) in box B.

C) both in box A and box C.

D) in box C.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

56

In a two-card kanban system:

A) each box of finished goods has a move card so it can be sent to the next step.

B) each box of raw material has a production card so it can be made into finished goods.

C) a downstream station pulls finished material out of a production area.

D) demand for more raw materials pushes finished goods to the finished goods area.

A) each box of finished goods has a move card so it can be sent to the next step.

B) each box of raw material has a production card so it can be made into finished goods.

C) a downstream station pulls finished material out of a production area.

D) demand for more raw materials pushes finished goods to the finished goods area.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

57

The number of kanbans in a production system is inversely related to the ________.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

58

In a two-card kanban system:

A) the production card signals when a move card should be moved to the next process step.

B) the move card signals when a container of parts should be produced.

C) the production card signals when a container that held parts should be returned to inventory.

D) the move card signals when a container of parts should move to the next process step.

A) the production card signals when a move card should be moved to the next process step.

B) the move card signals when a container of parts should be produced.

C) the production card signals when a container that held parts should be returned to inventory.

D) the move card signals when a container of parts should move to the next process step.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

59

Which of the following statements regarding supply chain synchronization using kanbans is BEST?

A) An interruption in the flow of goods within a supplier's assembly operations will have no effect on final assembly downstream in the supply chain.

B) For the system to work properly, demand rates must be relatively stable and interruptions must be minimized.

C) If final assembly demand doubles, there is no need to change kanbans at each of the suppliers.

D) Final assembly demand may rise or fall, but the sum of the kanbans among all suppliers in the supply chain will remain constant.

A) An interruption in the flow of goods within a supplier's assembly operations will have no effect on final assembly downstream in the supply chain.

B) For the system to work properly, demand rates must be relatively stable and interruptions must be minimized.

C) If final assembly demand doubles, there is no need to change kanbans at each of the suppliers.

D) Final assembly demand may rise or fall, but the sum of the kanbans among all suppliers in the supply chain will remain constant.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

60

Consider the adjacent work stations in this two card Kanban system.Work Center 3 has just pulled the Incoming Parts C box to their work station.Which of these statements is best?

A) The move card will move backward from Work Center 3 to Work Center 2.

B) The production card will move backward from Work Center 3 to Work Center 2.

C) The move card will move forward from Work Center 3 to Work Center 4.

D) Despite its name, the move card doesn't actually move from one station to the next, it will simply reside at Work Center 3 until the next box is finished.

A) The move card will move backward from Work Center 3 to Work Center 2.

B) The production card will move backward from Work Center 3 to Work Center 2.

C) The move card will move forward from Work Center 3 to Work Center 4.

D) Despite its name, the move card doesn't actually move from one station to the next, it will simply reside at Work Center 3 until the next box is finished.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

61

What are the consequences of unstable demand and interrupted flows on a supply chain managed with a lean philosophy?

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

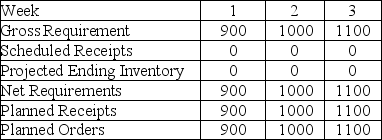

62

Use this material requirements planning record to explain how kanbans and MRP can be used together.This plant operates on a 40-hour week,and uses a 10% safety factor on a container size of 20 units with a half-day turnaround time on a container.What features of each system should be used and for what purposes?

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

63

Two modules are used to feed the final assembly station on an assembly line.The final assembly station must produce 250 units in an eight-hour day.Each finished unit needs two module A's and 3 module B's.The factory uses a standard sized container that can hold 25 module A's or 35 module B's.It takes 2 hours to fill and move a container of module A's,but only 90 minutes to fill and move a container of module B's.If both module assembly processes have safety factors of 15%,how many containers should be used for each? How many hours of demand will this satisfy?

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck

64

Describe the movements of parts and kanbans in a two-card kanban system.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 64 في هذه المجموعة.

فتح الحزمة

k this deck