Deck 8: Facility and Work Design

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

فتح الحزمة

قم بالتسجيل لفتح البطاقات في هذه المجموعة!

Unlock Deck

Unlock Deck

1/78

العب

ملء الشاشة (f)

Deck 8: Facility and Work Design

1

Product layouts offer higher flexibility with low productivity and process layouts have limited flexibility with high productivity.

False

2

In a product layout, a breakdown of one piece of equipment will not cause the entire process to shut down.

False

3

The facility layout in a library would most likely be a process layout.

True

4

Cycle time is related to the output rate and the available time to produce output.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

5

Cellular layouts are designed according to the functional characteristics of equipment much in the same fashion as process layouts.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

6

Flow-blocking and lack-of-work delays can be reduced by assigning an appropriate level of capacity at each workstation.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

7

Services such as legal and medical specialties employ cellular-type layouts as do manufacturers.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

8

Product layouts are less flexible than process layouts.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

9

The predominant layout type used in hospitals is the fixed-position layout.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

10

A fixed position layout is based on the sequence of operations that is performed during the manufacturing of a good or delivery of a service.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

11

Facility layout is not only concerned with the arrangement of physical facilities, but also the material handling capabilities within the facility.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

12

The objective of assembly line balancing is to group tasks among workstations so that the amount of work assigned to each workstation is highly variable, thus maximizing flexibility.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

13

Process layouts generally require less investment in equipment than product layouts because the equipment is less specialized.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

14

Workers in cellular layouts generally have greater responsibilities than those who work in product or process layouts.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

15

Cycle time should be smaller than the largest operation time.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

16

Cycle time in assembly line balancing is the maximum amount of time it takes to process a part at some workstation along the line.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

17

An assembly line is a type of product layout.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

18

Changes in goods and services for a firm's customer benefit package do not impact facility layouts.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

19

In a perfectly balanced assembly line, no bottlenecks exist.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

20

In a product layout such as an assembly line, a flow blocking delay occurs whenever one stage completes work and no units from the previous stage are waiting processing.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

21

Because of precedence relationships, assembly-line efficiencies will generally be very high.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

22

Teams are a way of accomplishing job enrichment.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

23

Ergonomics is the science that is concerned with determining specific job tasks and responsibilities.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

24

ALDEP is a process layout technique that focuses on materials handling costs as the primary solution.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

25

A ____ layout is an arrangement based on the sequence of operations that are performed during the manufacturing of a good or the delivery of a service.

A)Product

B)Process

C)Cellular

D)Fixed position

A)Product

B)Process

C)Cellular

D)Fixed position

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

26

Which of the following is not a common reason for facility layout studies?

A)There is significant change in demand or throughput volume.

B)A new good or service is introduced to the customer benefit package.

C)A new material supplier is used.

D)Different process, equipment and/or technology are installed.

A)There is significant change in demand or throughput volume.

B)A new good or service is introduced to the customer benefit package.

C)A new material supplier is used.

D)Different process, equipment and/or technology are installed.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

27

A line balancing solution has been developed for the assembly line for fertilizer spreaders at Green Grass, Inc.The desired output rate of 30 spreaders per hour will be achieved.The sum of times for all tasks performed on the line is 1200 seconds for each spreader assembled.Which of the following statements must be true?

A)The cycle time is 30 seconds per spreader.

B)The theoretical minimum number of work stations is 10.

C)If the solution calls for 12 stations, the efficiency is 80%.

D)If the solution calls for 11 stations, the efficiency is 80%.

A)The cycle time is 30 seconds per spreader.

B)The theoretical minimum number of work stations is 10.

C)If the solution calls for 12 stations, the efficiency is 80%.

D)If the solution calls for 11 stations, the efficiency is 80%.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

28

Which is true for product layout?

A)Very flexible

B)Lower work-in-process inventories

C)High job satisfaction

D)Easy to add new products

A)Very flexible

B)Lower work-in-process inventories

C)High job satisfaction

D)Easy to add new products

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

29

Self-managed teams perform entire jobs, rather than specialized assembly-line work.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

30

Job enlargement approaches give workers more variety of work, but not necessarily more responsibility.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

31

A ____ layout consists of a functional grouping of equipment or activities that do similar work.

A)Product

B)Process

C)Cellular

D)Fixed position

A)Product

B)Process

C)Cellular

D)Fixed position

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

32

A ____ layout is an arrangement based on self-contained groups of equipment needed to produce a particular set of goods or services.

A)Product

B)Process

C)Cellular

D)Fixed position

A)Product

B)Process

C)Cellular

D)Fixed position

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

33

CRAFT is a process layout technique that tries to improve on a current solution by exchanging two or three departments at a time to determine if total materials handling costs have been reduced.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

34

All of the following are common objectives of layout studies except

A)Minimize delays in materials handling and customer movement

B)Minimize the number of workstations

C)Provide for good housekeeping and maintenance

D)Maintain flexibility

A)Minimize delays in materials handling and customer movement

B)Minimize the number of workstations

C)Provide for good housekeeping and maintenance

D)Maintain flexibility

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

35

A Gallup study showed that workers who are allowed to personalize their workplaces were no more productive than those who are not allowed.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

36

An assembly line with 28 operations is to be balanced.The total amount of time required for all 28 operations is 39 minutes.The longest operation takes 2.2 minutes and the shortest takes 0.8 minutes.The line will operate for 450 minutes per day.

1. Determine the minimum and maximum cycle time.

2. What is the output rate if the cycle time is set at 2.2 minutes?

A)min cycle time = 0.8; max cycle time = 39; output rate = 204.5

B)min cycle time = 2.2; max cycle time = 39; output rate = 204.5

C)min cycle time = 2.2; max cycle time = 31.2; output rate = 562.5

D)min cycle time = 0.8; max cycle time = 2.2; output rate = 562.5

1. Determine the minimum and maximum cycle time.

2. What is the output rate if the cycle time is set at 2.2 minutes?

A)min cycle time = 0.8; max cycle time = 39; output rate = 204.5

B)min cycle time = 2.2; max cycle time = 39; output rate = 204.5

C)min cycle time = 2.2; max cycle time = 31.2; output rate = 562.5

D)min cycle time = 0.8; max cycle time = 2.2; output rate = 562.5

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

37

Virtual teams are empowered work teams that assume many traditional management responsibilities.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

38

The typical layout of facilities in a hospital would be an example of a ____ layout.

A)Product

B)Process

C)Cellular

D)Fixed position

A)Product

B)Process

C)Cellular

D)Fixed position

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

39

Assembly line balancing problems involving many distinct products (mixed-model line balancing) are generally easier to solve than single-model balancing problems because there are more alternatives available to assign tasks to workstations.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

40

The production of large goods such as airplanes is best accomplished using a ____ layout.

A)Product

B)Process

C)Cellular

D)Fixed position

A)Product

B)Process

C)Cellular

D)Fixed position

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

41

____ is vertical expansion of job duties to give the worker more responsibility.

A)Job enlargement

B)Job rotation

C)Job enrichment

D)Job design

A)Job enlargement

B)Job rotation

C)Job enrichment

D)Job design

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

42

The determination of specific job tasks and responsibilities is called ____.

A)Job design

B)Ergonomics

C)Job enlargement

D)Job enrichment

A)Job design

B)Ergonomics

C)Job enlargement

D)Job enrichment

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

43

Which of the following is not a disadvantage of virtual teams?

A)Security

B)Working hours

C)Synchronizing calendars

D)Socialization

A)Security

B)Working hours

C)Synchronizing calendars

D)Socialization

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

44

For a given cycle time in line balancing, assembly-line efficiency can be increased by

A)Speeding the line

B)Slowing the line

C)Decreasing the number of work stations

D)Increasing the number of work stations

A)Speeding the line

B)Slowing the line

C)Decreasing the number of work stations

D)Increasing the number of work stations

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

45

A(n) ____ performs entire jobs rather than specialized, assembly line work.

A)Virtual team

B)Self-managed team

C)Natural work team

D)Ergonomic team

A)Virtual team

B)Self-managed team

C)Natural work team

D)Ergonomic team

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

46

Considering ergonomics, which of the following does not fit?

A)Improving productivity

B)Group technology

C)Designing equipment and instrumentation

D)Considering physical capability of people

A)Improving productivity

B)Group technology

C)Designing equipment and instrumentation

D)Considering physical capability of people

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

47

Which is not true regarding fixed-position layout?

A)Synonymous with project

B)High demand volume

C)An example is a sporting event

D)Used with large items

A)Synonymous with project

B)High demand volume

C)An example is a sporting event

D)Used with large items

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

48

Which one of the following fits best with process layout?

A)Skilled workers

B)Standardization

C)Specialized equipment

D)Little work-in-process inventories

A)Skilled workers

B)Standardization

C)Specialized equipment

D)Little work-in-process inventories

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

49

____ classifies parts into families so that cellular layouts can be effectively used.

A)Ergonomics

B)Job enlargement

C)Group technology

D)CRAFT

A)Ergonomics

B)Job enlargement

C)Group technology

D)CRAFT

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

50

Discuss four reasons for conducting a facility-layout study.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

51

____ set their own goals and inspect their own work, often hire their own replacements and prepare their own budgets.

A)Virtual teams

B)Enlarged teams

C)Socio-technical teams

D)Self-managed teams

A)Virtual teams

B)Enlarged teams

C)Socio-technical teams

D)Self-managed teams

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

52

Which of the following is not a common approach for designing process layouts?

A)CRAFT

B)ALDEP

C)NIOSH

D)CORELAP

A)CRAFT

B)ALDEP

C)NIOSH

D)CORELAP

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

53

Differentiate among product layout, process layout, cellular layout, and fixed-position layout.State the advantages and disadvantages of each.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

54

Assembly line balancing

A)Is a one-time activity.

B)Tries to minimize the production rate for a given number of work stations.

C)Tries to minimize the number of work stations for a given production rate.

D)Attempts to load work into early work stations.

A)Is a one-time activity.

B)Tries to minimize the production rate for a given number of work stations.

C)Tries to minimize the number of work stations for a given production rate.

D)Attempts to load work into early work stations.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

55

All of the following are true regarding assembly lines except

A)Lower cost

B)Only one model can be assembled on a line

C)Makes good affordable to mass markets

D)Used in services,e.g., insurance policies and sorting mail

A)Lower cost

B)Only one model can be assembled on a line

C)Makes good affordable to mass markets

D)Used in services,e.g., insurance policies and sorting mail

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

56

Differentiate between a "flow blocking delay" and a "lack of work delay." How can each be reduced?

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

57

All of the following are limitations to process layout except

A)Higher movement and transportation costs

B)More complicated planning and control systems

C)Longer total processing time

D)Limited range of products

A)Higher movement and transportation costs

B)More complicated planning and control systems

C)Longer total processing time

D)Limited range of products

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

58

Explain assembly line balancing.Discuss the three types of information needed to balance an assembly line.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

59

Describe approaches used for process layout design.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

60

Which type of layout is best for high volumes of demand with few if any setups/changeovers?

A)Product

B)Process

C)Cellular

D)Fixed position

A)Product

B)Process

C)Cellular

D)Fixed position

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

61

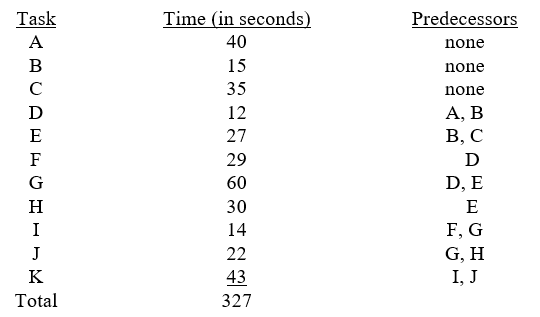

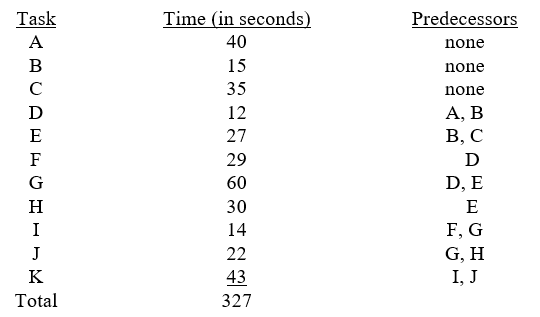

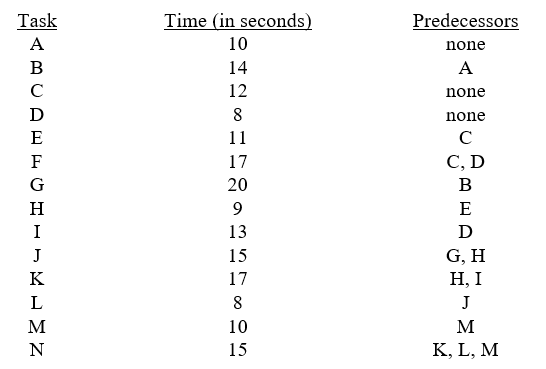

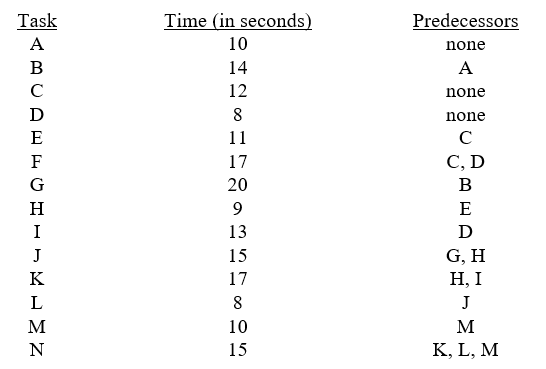

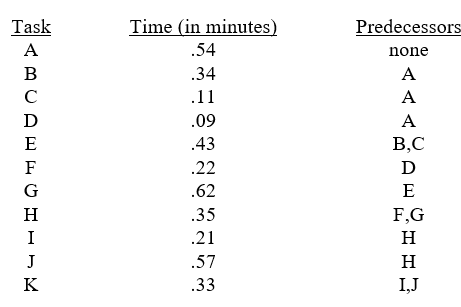

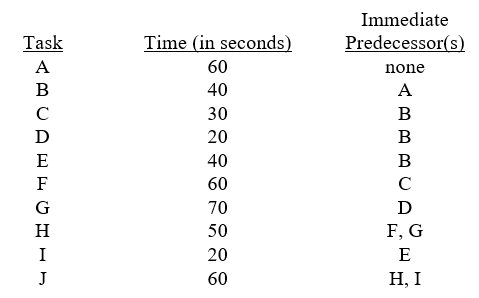

The eleven tasks necessary to assemble an MP3 player along with their time (in seconds) and immediate predecessor(s) is given below:

Using this information, determine the theoretical minimum number of work stations needed if the company wants to produce 600 units in a 9-hour (32,400 seconds) day.

Using this information, determine the theoretical minimum number of work stations needed if the company wants to produce 600 units in a 9-hour (32,400 seconds) day.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

62

Explain the role of ergonomics in job design.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

63

Discuss the advantages and disadvantages of utilizing virtual teams.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

64

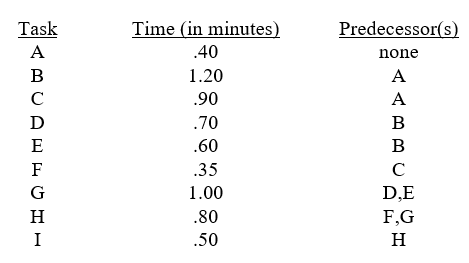

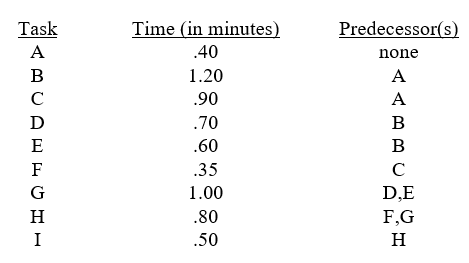

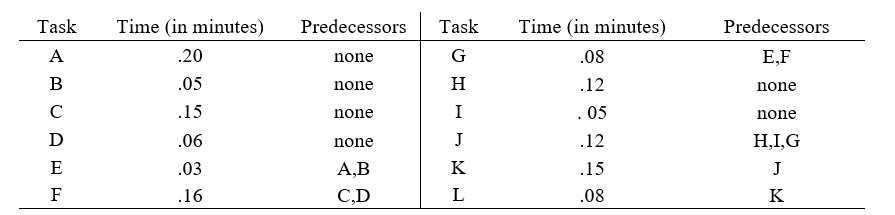

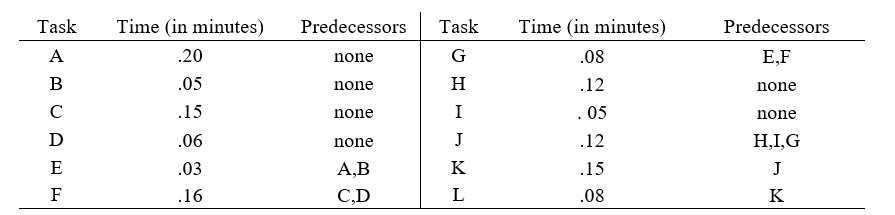

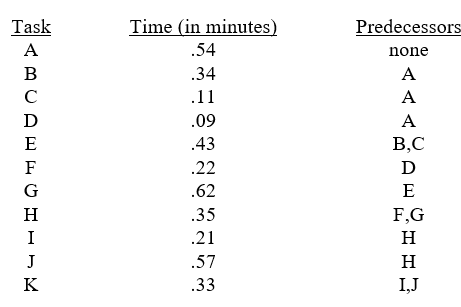

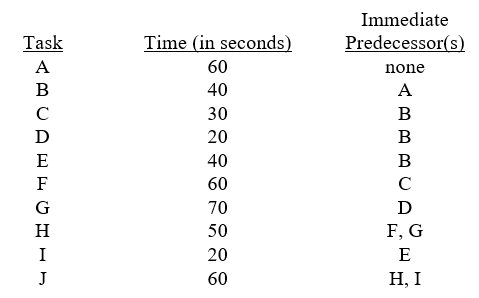

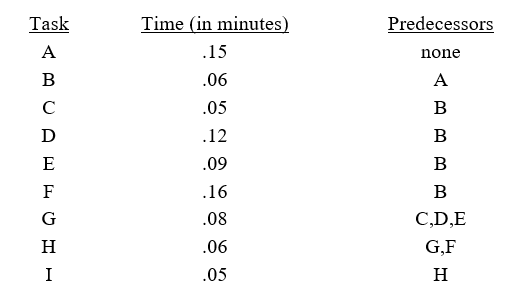

A company is setting up an assembly line to produce cellular telephones.They intend to use line balancing with the longest-task-time heuristic.They know the demand per hour is 40 phones and the productive time per hour is 54 minutes.Displayed below is the data they have collected regarding task precedence and times.

a.What is the cycle time?

b.What is the theoretical minimum number of workstations?

c.What tasks are assigned to the first workstation?

d.How many workstations are needed for the entire line?

e.What is the assembly-line efficiency?

a.What is the cycle time?

b.What is the theoretical minimum number of workstations?

c.What tasks are assigned to the first workstation?

d.How many workstations are needed for the entire line?

e.What is the assembly-line efficiency?

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

65

A product requires the following tasks to make it on an assembly line.Assume 7.6 hours per workday and 5 workdays per week.

a.Using only the information given, what would be the maximum output per day that can be achieved?

b.Assume that the activities have been assigned to five workstations.What is the line efficiency for a cycle time of 40 seconds?

a.Using only the information given, what would be the maximum output per day that can be achieved?

b.Assume that the activities have been assigned to five workstations.What is the line efficiency for a cycle time of 40 seconds?

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

66

Explain the socio-technical approach to job design and some ways to implement it.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

67

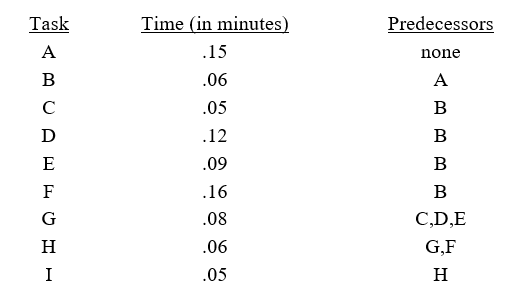

For the following assembly line data, balance the line for an output of 30 units in a 7.5 hour shift.Use the "longest task time first" rule.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

68

The twelve tasks necessary to assemble a food blender are listed below.The time to perform each task and the tasks that must immediately precede are also listed.200 blenders are needed per hour and 50 minutes per hour are productive:

a.Compute the cycle time per unit in minutes.

b.Compute the minimum number of workstations required.

c.Use the longest-task-time heuristic to balance the assembly line.

d.Compute the efficiency of your assembly line.

a.Compute the cycle time per unit in minutes.

b.Compute the minimum number of workstations required.

c.Use the longest-task-time heuristic to balance the assembly line.

d.Compute the efficiency of your assembly line.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

69

An assembly line with 28 activities is to be balanced.The total amount of time required for all 28 activities is 39 minutes.The longest activity is 2.2 minutes and the shortest is 0.8 minutes.The line will operate for 450 minutes per day.What is the assembly line efficiency with 11 stations and a product produced every 5 minutes?

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

70

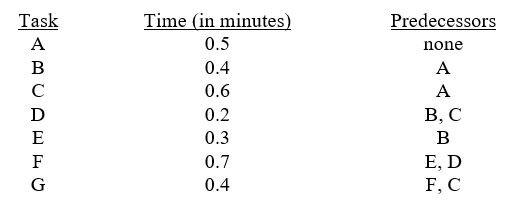

A small electronics company assembles power supplies for use in computers, printers and Fax machines.They want to set up an assembly line to make their operation more efficient and plan to use line balancing with the longest-task-time heuristic.The demand for power supplies is 70 per hour, and the productive time per hour is 52 minutes.The following table provides details on their operation.

a.What is the cycle time?

b.What is the theoretical minimum number of workstations?

c.What tasks go into the first workstation?

d.How many workstations are needed for the entire line?

e.What is the assembly-line efficiency?

a.What is the cycle time?

b.What is the theoretical minimum number of workstations?

c.What tasks go into the first workstation?

d.How many workstations are needed for the entire line?

e.What is the assembly-line efficiency?

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

71

An assembly line with 28 activities is to be balanced.The total amount of time required for all 28 activities is 39 minutes.The longest activity is 2.2 minutes and the shortest is 0.8 minutes.The line will operate for 450 minutes per day.Using a cycle time of 60 seconds, determine an assembly line balance by selecting the longest task available.Compute the total idle time, and assembly line efficiency.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

72

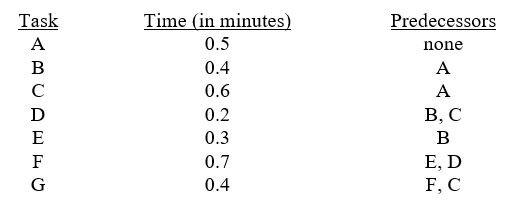

Consider the following assembly line information for manufacturing the latest cell phone.  The firm wants to produce 80 cell phones per hour.

The firm wants to produce 80 cell phones per hour.

a.What is the required cycle time?

b.Balance the assembly line using your choice of balancing heuristic, with the goal of minimizing the number of workstations needed? (Specify the task(s) assigned to each workstation.)

c.What is the efficiency of your assembly line?

d.Is this a good assembly line balancing solution? Explain.What do you recommend?

The firm wants to produce 80 cell phones per hour.

The firm wants to produce 80 cell phones per hour. a.What is the required cycle time?

b.Balance the assembly line using your choice of balancing heuristic, with the goal of minimizing the number of workstations needed? (Specify the task(s) assigned to each workstation.)

c.What is the efficiency of your assembly line?

d.Is this a good assembly line balancing solution? Explain.What do you recommend?

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

73

An assembly line with 28 operations is to be balanced.The total amount of time required for all 28 operations is 39 minutes.The longest operation takes 2.2 minutes and the shortest takes 0.8 minutes.The line will operate for 450 minutes per day.

a.Determine the minimum and maximum cycle time.

b.What is the maximum output rate that this assembly line can achieve?

c.What is the output rate if the cycle time is set at 2.2 minutes?

a.Determine the minimum and maximum cycle time.

b.What is the maximum output rate that this assembly line can achieve?

c.What is the output rate if the cycle time is set at 2.2 minutes?

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

74

In your first job you must set up an assembly line to assemble a computer mouse.The precedence diagram below is defined with task times in parentheses and stated in minutes.There are 480 minutes of assembly time per shift and there is one shift.The forecast (output rate) is 60 units per shift.

a.Compute the cycle time per unit in minutes.

b.Compute the minimum number of workstations required.

c.Use the longest-task-time heuristic to balance the assembly line.

d.Compute the efficiency of your assembly line.

a.Compute the cycle time per unit in minutes.

b.Compute the minimum number of workstations required.

c.Use the longest-task-time heuristic to balance the assembly line.

d.Compute the efficiency of your assembly line.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

75

An assembly line with 28 activities is to be balanced.The total amount of time required for all 28 activities is 39 minutes.The line will operate for 450 minutes per day.What must the cycle time be to achieve an output rate of 400 units/day?

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

76

List the many questions that must be addressed in designing a workstation.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

77

The Florida Appliance Company is installing an assembly line to produce vacuum cleaners, and you, as an operations manager, are responsible for balancing the line.The tasks to be performed are listed, along with their times and immediate predecessors.

The company is planning to operate 2 shifts per day, 8 hours per shift.The desired output rate of the line is 480 units per day.

The company is planning to operate 2 shifts per day, 8 hours per shift.The desired output rate of the line is 480 units per day.

a.Compute the cycle time per unit in minutes.

b.Compute the minimum number of workstations required.

c.Use the longest-task-time heuristic to balance the assembly line.

d.Compute the efficiency of your assembly line.

The company is planning to operate 2 shifts per day, 8 hours per shift.The desired output rate of the line is 480 units per day.

The company is planning to operate 2 shifts per day, 8 hours per shift.The desired output rate of the line is 480 units per day. a.Compute the cycle time per unit in minutes.

b.Compute the minimum number of workstations required.

c.Use the longest-task-time heuristic to balance the assembly line.

d.Compute the efficiency of your assembly line.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

78

The nine tasks necessary to assemble a vacuum cleaner are listed below.The time to perform each task and the tasks that must immediately precede are also listed.300 vacuums are needed per hour and 50 minutes per hour are productive.

a.Compute the cycle time per unit in minutes.

b.Compute the minimum number of workstations required.

c.Use the longest-task-time heuristic to balance the production line.

d.Compute the efficiency of the assembly line.

a.Compute the cycle time per unit in minutes.

b.Compute the minimum number of workstations required.

c.Use the longest-task-time heuristic to balance the production line.

d.Compute the efficiency of the assembly line.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck