Deck 15: Lean Accounting and Productivity Measurement

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

فتح الحزمة

قم بالتسجيل لفتح البطاقات في هذه المجموعة!

Unlock Deck

Unlock Deck

1/172

العب

ملء الشاشة (f)

Deck 15: Lean Accounting and Productivity Measurement

1

Implementing the value-stream structure requires an increase in employees.

False

2

The two lean accounting approaches are average-costing and value-stream cost reporting.

False

3

Value-stream costing reports the actual revenues and actual costs on a weekly basis for each value stream.

True

4

Employee empowerment is a major difference between traditional and lean environments.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

5

The value stream focuses on just value-added activities.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

6

Allocating efficiency chooses the least costly, technically efficient combination of inputs.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

7

Productivity measurement is a quantitative assessment of increases or decreases in productivity.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

8

Customer value is the difference between what a customer receives and what they give up.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

9

Productivity is concerned with the efficiency of input usage in producing output.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

10

Profile measurement provides a series of profiles for all operational measures.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

11

Partial measures allow managers to focus on the use of the total production and are easily interpreted.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

12

Lean manufacturing is concerned with eliminating waste in manufacturing processes.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

13

The disadvantage of using partial measures in isolation is that it can be misleading.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

14

A Box Scorecard is used by the lean control system to compare operational, capacity, and financial figures

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

15

The productivity measure of all inputs simultaneously is called total productivity measurement.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

16

Technical efficiency is concerned with a given input using no more than needed output.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

17

Lean manufacturing adds value by reducing labor costs.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

18

Profit-linked productivity measurement involves the measuring of the amount of profit related to productivity change.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

19

Operational partial measures are difficult to interpret by those within an organization.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

20

Changes in product-costing and operational control approaches are crucial to a value-stream based lean manufacturing system.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

21

Lean manufacturing benefits of better quality, reduced lead times, inventory reductions, and reduced setup times result in

A) lower manufacturing costs.

B) increased production rates.

C) reductions in innovative capabilities.

D) both a and b.

A) lower manufacturing costs.

B) increased production rates.

C) reductions in innovative capabilities.

D) both a and b.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

22

The component which provides a server or vector of separate and distinct partial operational measures is called __________ measurement.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

23

Maximizing customer value, on-demand production, and zero setup times are realized in the pursuit of __________ .

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

24

__________ allocation is the only allocation used regularly in a value stream cost assignment.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

25

The process of producing output efficiently using the least amount of inputs is

called __________ .

called __________ .

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

26

The quantitative assessment of productivity changes is called __________ measurement.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

27

The accounting approach designed to support and encourage lean manufacturing is called __________ accounting.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

28

Identifying value streams may be accomplished by using a two-dimensional matrix where __________ are listed on one dimension, and __________ on a second dimension.

or

or

or

or

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

29

The achievement of __________ efficiency and __________ efficiency is the point of total productive efficiency.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

30

The departments or cells that contain all the related operations needed to produce a family of products are called __________ .

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

31

The worth of one or more features of a product for which customers are willing to pay is called __________ .

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

32

Which is NOT a benefit of lean manufacturing?

A) increased productivity

B) reduced lead times

C) reduced direct labor costs

D) reductions in inventory

A) increased productivity

B) reduced lead times

C) reduced direct labor costs

D) reductions in inventory

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

33

Lean manufacturing is best defined as

A) an operating approach that reports on the effectiveness of the management of the organization.

B) an operating approach designed to eliminate waste and maximize customer value.

C) an operating approach that is designed to analyze the activities of the organization.

D) an operating approach that is designed to compute variances between expectations and actual performance.

A) an operating approach that reports on the effectiveness of the management of the organization.

B) an operating approach designed to eliminate waste and maximize customer value.

C) an operating approach that is designed to analyze the activities of the organization.

D) an operating approach that is designed to compute variances between expectations and actual performance.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

34

The point at which technical and allocative efficiency are achieved is called __________ efficiency.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

35

The __________ is used by the lean control system to compare operational, capacity, and financial metrics.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

36

The difference between the total profit change and the profit-linked productivity change is

called the __________ component.

called the __________ component.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

37

A difference between Toyota's lean manufacturing system and Ford's lean enterprise system is

A) Toyota incorporated employee empowerment, team structure, cellular manufacturing, small batches, and reduced setup times as integral pieces of their system.

B) Toyota was not structured to deal with product variety.

C) Toyota valued process over employees.

D) Low volume products were not compatible with either system.

A) Toyota incorporated employee empowerment, team structure, cellular manufacturing, small batches, and reduced setup times as integral pieces of their system.

B) Toyota was not structured to deal with product variety.

C) Toyota valued process over employees.

D) Low volume products were not compatible with either system.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

38

In a lean environment, many overhead costs are assigned to products as directly __________ costs.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

39

Which of the following is NOT a characteristic of a lean manufacturing system?

A) delivery of the right product in the right quantity

B) zero defect

C) delivery of product the exact time a customer needs it

D) all of the above

A) delivery of the right product in the right quantity

B) zero defect

C) delivery of product the exact time a customer needs it

D) all of the above

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

40

An assessment of productive efficiency for all inputs combined is called __________ measurement.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

41

The new product value stream focuses on

A) developing new products for new customers.

B) providing current products to current customers.

C) providing current products to new customers and new products to new customers.

D) the production, sale, and delivery of products.

A) developing new products for new customers.

B) providing current products to current customers.

C) providing current products to new customers and new products to new customers.

D) the production, sale, and delivery of products.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

42

The departments or cells which contain all the operations in close proximity that are needed to produce a family of products.

A) Manufacturing cells

B) Value stream cells

C) Batch departments

D) Plant departments

A) Manufacturing cells

B) Value stream cells

C) Batch departments

D) Plant departments

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

43

The processing department can produce one unit every 5 minutes and is the last department before the finishing department. Under traditional manufacturing where a batch equals 10 units, how long will it be before the first unit in the batch can move from the processing department to the finishing department?

A) 5 minutes

B) 50 minutes

C) 10 minutes

D) not enough information is given

A) 5 minutes

B) 50 minutes

C) 10 minutes

D) not enough information is given

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

44

In a demand-pull system

A) production is triggered by a forecast.

B) production is triggered by a customer order.

C) production is triggered by a vendor shipment.

D) production is triggered by an economic reorder point.

A) production is triggered by a forecast.

B) production is triggered by a customer order.

C) production is triggered by a vendor shipment.

D) production is triggered by an economic reorder point.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

45

Reducing the time it takes to configure equipment to produce a different product is an example of

A) cellular manufacturing.

B) batch processing.

C) reduced setup/changeover times.

D) value flow stream.

A) cellular manufacturing.

B) batch processing.

C) reduced setup/changeover times.

D) value flow stream.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

46

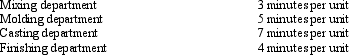

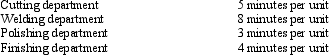

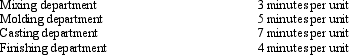

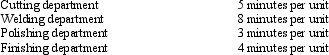

Figure 15-1 The following information relates to Lancashire Manufacturing:

To produce a unit of product:

There is a wait time of 8 minutes before the mixing department begins a batch, 5 minutes between the mixing and molding departments, a move and pre-wait between molding and casting of 10 minutes, and a move and pre-wait between the casting and finishing departments of 12 minutes.

There is a wait time of 8 minutes before the mixing department begins a batch, 5 minutes between the mixing and molding departments, a move and pre-wait between molding and casting of 10 minutes, and a move and pre-wait between the casting and finishing departments of 12 minutes.

Refer to Figure 15-1. Which area represents the bottleneck operation?

A) finishing

B) casting

C) molding

D) mixing

To produce a unit of product:

There is a wait time of 8 minutes before the mixing department begins a batch, 5 minutes between the mixing and molding departments, a move and pre-wait between molding and casting of 10 minutes, and a move and pre-wait between the casting and finishing departments of 12 minutes.

There is a wait time of 8 minutes before the mixing department begins a batch, 5 minutes between the mixing and molding departments, a move and pre-wait between molding and casting of 10 minutes, and a move and pre-wait between the casting and finishing departments of 12 minutes.Refer to Figure 15-1. Which area represents the bottleneck operation?

A) finishing

B) casting

C) molding

D) mixing

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

47

To identify value streams using a two-dimensional matrix, the following two items must be utilized:

A) value indicators; costs

B) activities/processes; costs

C) quality indicators; products

D) activities/processes; products

A) value indicators; costs

B) activities/processes; costs

C) quality indicators; products

D) activities/processes; products

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

48

Lean manufacturing shares many of the same methodologies as

A) activity-based management.

B) JIT manufacturing.

C) process costing.

D) none of the above.

A) activity-based management.

B) JIT manufacturing.

C) process costing.

D) none of the above.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

49

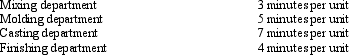

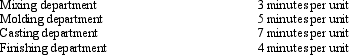

Figure 15-1 The following information relates to Lancashire Manufacturing:

To produce a unit of product:

There is a wait time of 8 minutes before the mixing department begins a batch, 5 minutes between the mixing and molding departments, a move and pre-wait between molding and casting of 10 minutes, and a move and pre-wait between the casting and finishing departments of 12 minutes.

There is a wait time of 8 minutes before the mixing department begins a batch, 5 minutes between the mixing and molding departments, a move and pre-wait between molding and casting of 10 minutes, and a move and pre-wait between the casting and finishing departments of 12 minutes.

Refer to Figure 15-1. How long does it take to produce a batch of 20 units under a traditional manufacturing approach?

A) 380 minutes

B) 415 minutes

C) 35 minutes

D) none of the above

To produce a unit of product:

There is a wait time of 8 minutes before the mixing department begins a batch, 5 minutes between the mixing and molding departments, a move and pre-wait between molding and casting of 10 minutes, and a move and pre-wait between the casting and finishing departments of 12 minutes.

There is a wait time of 8 minutes before the mixing department begins a batch, 5 minutes between the mixing and molding departments, a move and pre-wait between molding and casting of 10 minutes, and a move and pre-wait between the casting and finishing departments of 12 minutes.Refer to Figure 15-1. How long does it take to produce a batch of 20 units under a traditional manufacturing approach?

A) 380 minutes

B) 415 minutes

C) 35 minutes

D) none of the above

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

50

The worth of one or more features of a product for which the customer is willing to pay is defined as:

A) Value

B) Quality

C) Efficiency

D) Innovation

A) Value

B) Quality

C) Efficiency

D) Innovation

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

51

The value stream

A) is made up of all activities, both value-added and non-value-added, required to bring a product group or service from its starting point to a finished product in the hands of the customer.

B) is made up value-added activities required to bring a product group or service from its starting point to a finished product in the hands of the customer.

C) is where the production stream is triggered by forecast.

D) is a series of steps designed to set target costs.

A) is made up of all activities, both value-added and non-value-added, required to bring a product group or service from its starting point to a finished product in the hands of the customer.

B) is made up value-added activities required to bring a product group or service from its starting point to a finished product in the hands of the customer.

C) is where the production stream is triggered by forecast.

D) is a series of steps designed to set target costs.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

52

Identification of a "value stream," pursuit of perfection, and making value flow without interruption are examples of

A) total quality management.

B) activity-based costing.

C) principles of lean thinking.

D) Kanban processing.

A) total quality management.

B) activity-based costing.

C) principles of lean thinking.

D) Kanban processing.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

53

There are two basic types of non-value added activities. They are

A) activities avoidable in the long run and activities unavoidable in the short run due to current technology or production methods.

B) activities avoidable in the short run and activities unavoidable in the long run due to current technology or production methods.

C) activities unavoidable in the short run due to current technology and activities avoidable due to production methods.

D) activities avoidable in the short run and activities unavoidable in the short run due to current technology or production methods.

A) activities avoidable in the long run and activities unavoidable in the short run due to current technology or production methods.

B) activities avoidable in the short run and activities unavoidable in the long run due to current technology or production methods.

C) activities unavoidable in the short run due to current technology and activities avoidable due to production methods.

D) activities avoidable in the short run and activities unavoidable in the short run due to current technology or production methods.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

54

In a traditional manufacturing setup

A) there is significant move and wait time.

B) organization is by function into departments.

C) products are produced in large batches.

D) all of the above.

A) there is significant move and wait time.

B) organization is by function into departments.

C) products are produced in large batches.

D) all of the above.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

55

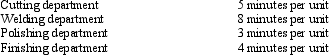

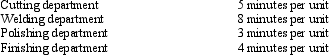

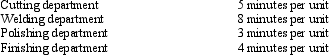

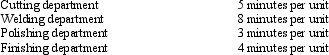

Figure 15-2 The following information relates to Cranmore Manufacturing:

To produce a unit of product:

There is a wait time of 5 minutes before the cutting department begins a batch, 15 minutes between the cutting and welding departments, a move and pre-wait between welding and polishing of 12 minutes, and a move and pre-wait between the polishing and finishing departments of 8 minutes.

There is a wait time of 5 minutes before the cutting department begins a batch, 15 minutes between the cutting and welding departments, a move and pre-wait between welding and polishing of 12 minutes, and a move and pre-wait between the polishing and finishing departments of 8 minutes.

Refer to Figure 15-2. What is the cycle time of operation?

A) 60 minutes

B) 20 minutes

C) 35 minutes

D) 16 minutes

To produce a unit of product:

There is a wait time of 5 minutes before the cutting department begins a batch, 15 minutes between the cutting and welding departments, a move and pre-wait between welding and polishing of 12 minutes, and a move and pre-wait between the polishing and finishing departments of 8 minutes.

There is a wait time of 5 minutes before the cutting department begins a batch, 15 minutes between the cutting and welding departments, a move and pre-wait between welding and polishing of 12 minutes, and a move and pre-wait between the polishing and finishing departments of 8 minutes.Refer to Figure 15-2. What is the cycle time of operation?

A) 60 minutes

B) 20 minutes

C) 35 minutes

D) 16 minutes

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

56

Figure 15-2 The following information relates to Cranmore Manufacturing:

To produce a unit of product:

There is a wait time of 5 minutes before the cutting department begins a batch, 15 minutes between the cutting and welding departments, a move and pre-wait between welding and polishing of 12 minutes, and a move and pre-wait between the polishing and finishing departments of 8 minutes.

There is a wait time of 5 minutes before the cutting department begins a batch, 15 minutes between the cutting and welding departments, a move and pre-wait between welding and polishing of 12 minutes, and a move and pre-wait between the polishing and finishing departments of 8 minutes.

Refer to Figure 15-2. If Cranmore produces in batches of 10 units, how much time would have elapsed by the time the 10th unit is produced under a manufacturing cell environment (assuming the cell is processing continuously)?

A) 60 minutes

B) 65 minutes

C) 150 minutes

D) some other amount

To produce a unit of product:

There is a wait time of 5 minutes before the cutting department begins a batch, 15 minutes between the cutting and welding departments, a move and pre-wait between welding and polishing of 12 minutes, and a move and pre-wait between the polishing and finishing departments of 8 minutes.

There is a wait time of 5 minutes before the cutting department begins a batch, 15 minutes between the cutting and welding departments, a move and pre-wait between welding and polishing of 12 minutes, and a move and pre-wait between the polishing and finishing departments of 8 minutes.Refer to Figure 15-2. If Cranmore produces in batches of 10 units, how much time would have elapsed by the time the 10th unit is produced under a manufacturing cell environment (assuming the cell is processing continuously)?

A) 60 minutes

B) 65 minutes

C) 150 minutes

D) some other amount

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

57

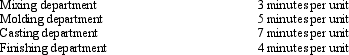

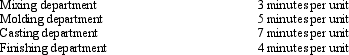

Figure 15-1 The following information relates to Lancashire Manufacturing:

To produce a unit of product:

There is a wait time of 8 minutes before the mixing department begins a batch, 5 minutes between the mixing and molding departments, a move and pre-wait between molding and casting of 10 minutes, and a move and pre-wait between the casting and finishing departments of 12 minutes.

There is a wait time of 8 minutes before the mixing department begins a batch, 5 minutes between the mixing and molding departments, a move and pre-wait between molding and casting of 10 minutes, and a move and pre-wait between the casting and finishing departments of 12 minutes.

Refer to Figure 15-1. What is the production rate?

A) 8.6 units per hour

B) 7 units per hour

C) 21 units per hour

D) 19 units per hour

To produce a unit of product:

There is a wait time of 8 minutes before the mixing department begins a batch, 5 minutes between the mixing and molding departments, a move and pre-wait between molding and casting of 10 minutes, and a move and pre-wait between the casting and finishing departments of 12 minutes.

There is a wait time of 8 minutes before the mixing department begins a batch, 5 minutes between the mixing and molding departments, a move and pre-wait between molding and casting of 10 minutes, and a move and pre-wait between the casting and finishing departments of 12 minutes.Refer to Figure 15-1. What is the production rate?

A) 8.6 units per hour

B) 7 units per hour

C) 21 units per hour

D) 19 units per hour

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

58

The order fulfillment value stream focuses on

A) developing new products for new customers.

B) providing current products to current customers.

C) providing current products to new customers and new products to new customers.

D) the production, sale, and delivery of products.

A) developing new products for new customers.

B) providing current products to current customers.

C) providing current products to new customers and new products to new customers.

D) the production, sale, and delivery of products.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

59

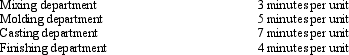

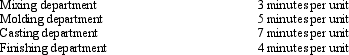

Figure 15-1 The following information relates to Lancashire Manufacturing:

To produce a unit of product:

There is a wait time of 8 minutes before the mixing department begins a batch, 5 minutes between the mixing and molding departments, a move and pre-wait between molding and casting of 10 minutes, and a move and pre-wait between the casting and finishing departments of 12 minutes.

There is a wait time of 8 minutes before the mixing department begins a batch, 5 minutes between the mixing and molding departments, a move and pre-wait between molding and casting of 10 minutes, and a move and pre-wait between the casting and finishing departments of 12 minutes.

Refer to Figure 15-1. How long would it take to process the first unit of a 20-unit batch under a cellular manufacturing setup?

A) 21 minutes

B) 12 minutes

C) 19 minutes

D) 60 minutes

To produce a unit of product:

There is a wait time of 8 minutes before the mixing department begins a batch, 5 minutes between the mixing and molding departments, a move and pre-wait between molding and casting of 10 minutes, and a move and pre-wait between the casting and finishing departments of 12 minutes.

There is a wait time of 8 minutes before the mixing department begins a batch, 5 minutes between the mixing and molding departments, a move and pre-wait between molding and casting of 10 minutes, and a move and pre-wait between the casting and finishing departments of 12 minutes.Refer to Figure 15-1. How long would it take to process the first unit of a 20-unit batch under a cellular manufacturing setup?

A) 21 minutes

B) 12 minutes

C) 19 minutes

D) 60 minutes

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

60

The production rate

A) tells how many units of a product can be produced by the manufacturing cell.

B) calculates how many minutes it takes an operation to process one unit of product.

C) calculates the processing time of the slowest department.

D) calculates the wait and move time of a production.

A) tells how many units of a product can be produced by the manufacturing cell.

B) calculates how many minutes it takes an operation to process one unit of product.

C) calculates the processing time of the slowest department.

D) calculates the wait and move time of a production.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

61

In calculating product costs for a value stream with multiple products, average product costs are a good estimate of individual product costs if

A) the products are similar and consume resources in approximately the same proportion.

B) the product mix is relatively stable.

C) the products are homogenous.

D) all of the above.

A) the products are similar and consume resources in approximately the same proportion.

B) the product mix is relatively stable.

C) the products are homogenous.

D) all of the above.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

62

Emphasis on departmental efficiency

A) causes bottleneck departments to over-produce and build work-in-process inventories.

B) causes stock outs related to demand-pull systems.

C) is a critical component of a lean accounting system.

D) none of the above.

A) causes bottleneck departments to over-produce and build work-in-process inventories.

B) causes stock outs related to demand-pull systems.

C) is a critical component of a lean accounting system.

D) none of the above.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

63

Which of the following is NOT considered a major source of waste?

A) waiting

B) joint products

C) overproduction of goods not needed

D) defective products

A) waiting

B) joint products

C) overproduction of goods not needed

D) defective products

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

64

Which of the following is true in regards to a lean accounting system?

A) The cost of people with specialized skills, such as industrial engineers, are allocated to all manufacturing cells based on an activity driver.

B) Workers are multiskilled and responsible for setting up equipment, maintaining equipment, and operating equipment.

C) Implementing a value stream system will require more workers.

D) Workers are highly skilled in one specialized area or activity and are not expected to spend time on other value-added activities.

A) The cost of people with specialized skills, such as industrial engineers, are allocated to all manufacturing cells based on an activity driver.

B) Workers are multiskilled and responsible for setting up equipment, maintaining equipment, and operating equipment.

C) Implementing a value stream system will require more workers.

D) Workers are highly skilled in one specialized area or activity and are not expected to spend time on other value-added activities.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

65

The pursuit of perfection is realized in

A) zero setup times.

B) producing on demand.

C) maximizing customer value.

D) all of the above.

A) zero setup times.

B) producing on demand.

C) maximizing customer value.

D) all of the above.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

66

Figure 15-2 The following information relates to Cranmore Manufacturing:

To produce a unit of product:

There is a wait time of 5 minutes before the cutting department begins a batch, 15 minutes between the cutting and welding departments, a move and pre-wait between welding and polishing of 12 minutes, and a move and pre-wait between the polishing and finishing departments of 8 minutes.

There is a wait time of 5 minutes before the cutting department begins a batch, 15 minutes between the cutting and welding departments, a move and pre-wait between welding and polishing of 12 minutes, and a move and pre-wait between the polishing and finishing departments of 8 minutes.

Refer to Figure 16-2. What is the production rate?

A) 12 units per hour

B) 20 units per hour

C) 15 units per hour

D) 7.5 units per hour

To produce a unit of product:

There is a wait time of 5 minutes before the cutting department begins a batch, 15 minutes between the cutting and welding departments, a move and pre-wait between welding and polishing of 12 minutes, and a move and pre-wait between the polishing and finishing departments of 8 minutes.

There is a wait time of 5 minutes before the cutting department begins a batch, 15 minutes between the cutting and welding departments, a move and pre-wait between welding and polishing of 12 minutes, and a move and pre-wait between the polishing and finishing departments of 8 minutes.Refer to Figure 16-2. What is the production rate?

A) 12 units per hour

B) 20 units per hour

C) 15 units per hour

D) 7.5 units per hour

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

67

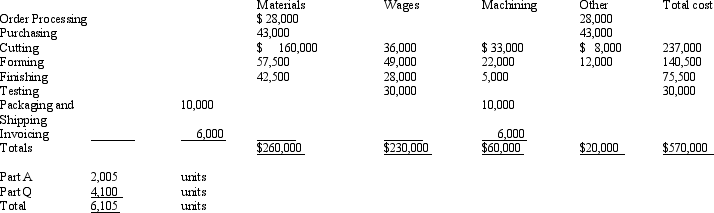

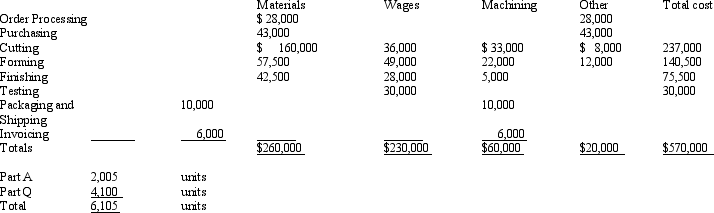

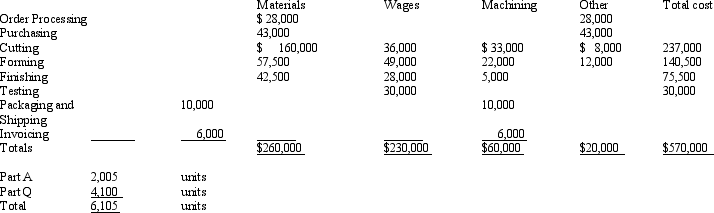

Figure 15 - 3 Based on the following information:

Refer to Figure 15-3. What is the product cost based on total average conversion cost? (Round to nearest cent.)

Refer to Figure 15-3. What is the product cost based on total average conversion cost? (Round to nearest cent.)

A) $100.56

B) $48.32

C) $36.04

D) $50.78

Refer to Figure 15-3. What is the product cost based on total average conversion cost? (Round to nearest cent.)

Refer to Figure 15-3. What is the product cost based on total average conversion cost? (Round to nearest cent.)A) $100.56

B) $48.32

C) $36.04

D) $50.78

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

68

In a lean environment, many overhead costs are assigned to

A) products using driver tracing.

B) products as directly traceable costs.

C) products using allocation methods.

D) costs using plantwide overhead rates.

A) products using driver tracing.

B) products as directly traceable costs.

C) products using allocation methods.

D) costs using plantwide overhead rates.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

69

The document used by the lean control system that compares operational, capacity, and financial metrics with prior week performances and with a future desired state is called:

A) balanced scorecard

B) profit analysis worksheet

C) box scorecard

D) performance improvement plan

A) balanced scorecard

B) profit analysis worksheet

C) box scorecard

D) performance improvement plan

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

70

If a facility has costs of $100,000 per year and 20,000 square feet, and if 19,000 square feet are absorbed by the value streams, what happens to the unabsorbed cost of the remaining 1,000 feet?

A) allocated to all the value streams based on proportionate square foot usage

B) assigned to all value streams equally

C) absorbed by the largest value stream

D) deducted from revenue as a separate item

A) allocated to all the value streams based on proportionate square foot usage

B) assigned to all value streams equally

C) absorbed by the largest value stream

D) deducted from revenue as a separate item

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

71

In the calculation of product costs for value streams with multiple products, units shipped instead of units produced is used as the denominator because

A) it reduces conversion costs assigned to the value stream.

B) it motivates managers to reduce inventories.

C) units shipped are always greater than units produced.

D) units shipped is not used.

A) it reduces conversion costs assigned to the value stream.

B) it motivates managers to reduce inventories.

C) units shipped are always greater than units produced.

D) units shipped is not used.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

72

The only allocation used regularly in a value stream cost assignment is

A) facilities.

B) depreciation.

C) maintenance.

D) setup costs.

A) facilities.

B) depreciation.

C) maintenance.

D) setup costs.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

73

Which of the following is NOT considered a major source of waste?

A) costs spent on defect detection

B) unnecessary movement of goods

C) unnecessary transport of goods

D) design of goods and services that don't meet the needs of the customer

A) costs spent on defect detection

B) unnecessary movement of goods

C) unnecessary transport of goods

D) design of goods and services that don't meet the needs of the customer

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

74

Which of the following is a reason traditional costing approaches may NOT work in a lean manufacturing environment?

A) Standard costing variances encourage overproduction.

B) Distorted product costs may conceal the outcome of success of a lean system.

C) Traditional operational controls work against demand-pull systems.

D) all of the above.

A) Standard costing variances encourage overproduction.

B) Distorted product costs may conceal the outcome of success of a lean system.

C) Traditional operational controls work against demand-pull systems.

D) all of the above.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

75

With multiple products in a value stream, unit cost will increase if

A) more units are shipped than produced.

B) more units are produced than shipped.

C) average conversion cost is used instead of total average cost.

D) none of the above.

A) more units are shipped than produced.

B) more units are produced than shipped.

C) average conversion cost is used instead of total average cost.

D) none of the above.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

76

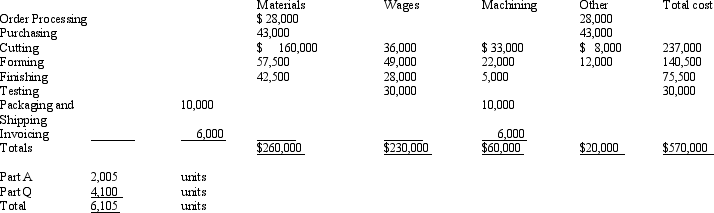

Figure 15 - 3 Based on the following information:

Refer to Figure 15-3. What is the product cost based on total average cost? (Round to nearest cent.)

Refer to Figure 15-3. What is the product cost based on total average cost? (Round to nearest cent.)

A) $54.05

B) $42.59

C) $48.32

D) $93.37

Refer to Figure 15-3. What is the product cost based on total average cost? (Round to nearest cent.)

Refer to Figure 15-3. What is the product cost based on total average cost? (Round to nearest cent.)A) $54.05

B) $42.59

C) $48.32

D) $93.37

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

77

Why might labor costs be reduced in a value stream system?

A) The elimination of the need for any specialized skilled employees such as industrial engineers or production schedulers.

B) The labor costs of industrial engineers and production schedulers can be pooled and allocated to the value streams.

C) Some of the workers can be cross-trained to perform value-added activities within the value stream.

D) none of the above.

A) The elimination of the need for any specialized skilled employees such as industrial engineers or production schedulers.

B) The labor costs of industrial engineers and production schedulers can be pooled and allocated to the value streams.

C) Some of the workers can be cross-trained to perform value-added activities within the value stream.

D) none of the above.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

78

The JIT solution

A) requires carrying materials inventory in order to lower the cost of inventory without production delays.

B) requires selection of vendors based on lowest cost alone.

C) exploits supplier linkages by negotiating long-term contracts with a few chosen suppliers located closest to the production facility and establishing more supplier involvement.

D) requires a solid forecast to push production.

A) requires carrying materials inventory in order to lower the cost of inventory without production delays.

B) requires selection of vendors based on lowest cost alone.

C) exploits supplier linkages by negotiating long-term contracts with a few chosen suppliers located closest to the production facility and establishing more supplier involvement.

D) requires a solid forecast to push production.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

79

Which of the following is NOT a limitation of a value stream cost assignment?

A) Initially, it may not be possible to allocate all the people needed in a value stream to that stream exclusively.

B) There will always be some individuals whose related costs will remain outside of any particular value stream.

C) A value stream is usually organized around a family of products.

D) Having a value stream for each product is not practical.

A) Initially, it may not be possible to allocate all the people needed in a value stream to that stream exclusively.

B) There will always be some individuals whose related costs will remain outside of any particular value stream.

C) A value stream is usually organized around a family of products.

D) Having a value stream for each product is not practical.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck

80

What is the usual formula for calculating product costs for value streams with multiple products?

A) total value stream cost of period / units shipped for period

B) budgeted value stream cost of period / units shipped for period

C) total value stream cost of period / units sold for period

D) budgeted value stream cost of period / forecasted units shipped for period

A) total value stream cost of period / units shipped for period

B) budgeted value stream cost of period / units shipped for period

C) total value stream cost of period / units sold for period

D) budgeted value stream cost of period / forecasted units shipped for period

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 172 في هذه المجموعة.

فتح الحزمة

k this deck