Deck 15: Resource Planning

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

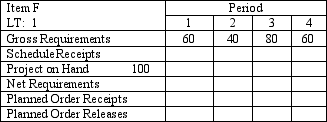

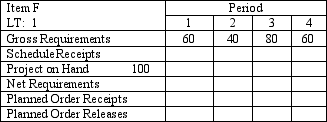

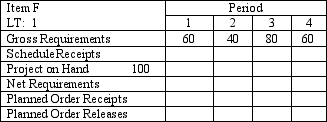

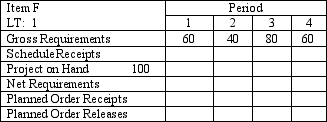

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

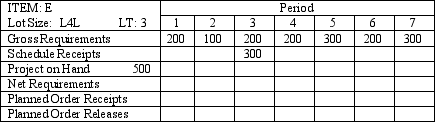

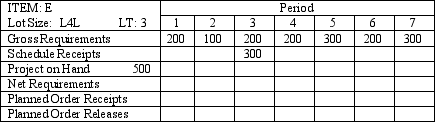

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

فتح الحزمة

قم بالتسجيل لفتح البطاقات في هذه المجموعة!

Unlock Deck

Unlock Deck

1/82

العب

ملء الشاشة (f)

Deck 15: Resource Planning

1

An enterprise resource planning (ERP)system shares information across functional areas.

True

2

The application modules that comprise the ERP system are designed to support only customer relationship management processes.

False

3

A load profile displays underloads and overloads.

True

4

Material requirements planning (MRP)is useful for managing and scheduling discrete demand items.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

5

The master production schedule (MPS)is a major output of the MRP process.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

6

A forecast of dependent demand requirements is one of the major inputs into the MRP process.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

7

Material requirements planning (MRP)translates the master production schedule into requirements for components,subassemblies,and raw materials.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

8

Lot sizing rules are used in MRP to determine work or purchase order quantities.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

9

Modular bills of material are used to group small,lose parts together into a kit.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

10

Information concerning on-hand quantities,lot sizes and,lead time,figures can be found in the master production schedule (MPS).

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

11

ERP systems are only concerned with production and marketing processes.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

12

Capacity requirement planning (CRP)converts the material plan into labor and machine workloads.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

13

The optimal time required to manufacture a product is called its cumulative lead time.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

14

Customer relationship management (CRM)software plans and executes business processes that involve customer interactions.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

15

Very simple products typically do not require material requirements planning (MRP)to plan production or monitor inventory levels.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

16

The periodic order quantity (POQ)lot sizing technique that places orders every demand period.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

17

Planned order releases at one level of a product structure generate gross requirements at the next level.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

18

A material requirements planning (MRP)system serves as both an inventory control system and as a production scheduling system.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

19

One objective of material requirements planning (MRP)is to utilize all available capacity.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

20

Capacity requirements planning (CRP)projects the load from a given material plan onto the capacity of a system.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

21

Load leveling is used to resolve underloaded and overloaded capacity conditions.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

22

The last stage in ERP implementation involves analyzing business processes.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

23

The total length of time to purchase an item from a supplier is called its cumulative lead time.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

24

The quantities reported on a master production schedule may reflect a combination of actual and forecasted demand.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

25

The quantities displayed on a master production schedule represent production and not actual demand.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

26

A phantom bill of material is appropriate when a product consists of assemblies that are later combined to form a variety of final products.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

27

Customer relationship management systems change the focus from managing products to managing customers.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

28

Material requirements planning (MRP)is more useful for simple products and less useful for complex products.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

29

The product structure file lists all of the following except

A)the product's demand.

B)the items that go into the product.

C)a brief description of each item.

D)when and in what quantity each item is needed in the assembly process.

A)the product's demand.

B)the items that go into the product.

C)a brief description of each item.

D)when and in what quantity each item is needed in the assembly process.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

30

Material requirements planning (MRP)is a useful for all of the following except

A)dependent demand items.

B)discrete demand items.

C)independent demand items.

D)erratic orders.

A)dependent demand items.

B)discrete demand items.

C)independent demand items.

D)erratic orders.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

31

Firms that successfully implement an MRP system no longer require cycle counting of inventory.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

32

Single-source ERP systems are often easier to integrate than systems built using the best-in-breed approach.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

33

Because the item master file is an input into the MRP process it should be updated to reflect any revisions or changes.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

34

A _______________ of material is used to plan the production of products with many optional features.

A)K-bill

B)modular bill

C)phantom bill

D)time-phased bill

A)K-bill

B)modular bill

C)phantom bill

D)time-phased bill

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

35

37.All of the following are inputs into the MRP process except

A)the master production schedule.

B)the product structure file.

C)the item master file.

D)the planned order report.

A)the master production schedule.

B)the product structure file.

C)the item master file.

D)the planned order report.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

36

Enterprise resource planning integrates business processes at the expense of customer interaction.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

37

A matrix is used to organize and display the information generated by the MRP process.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

38

ERP application modules can be used alone or in combination.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

39

A phantom bill of material is used

A)to group small,loose parts together.

B)when the product is manufactured in major subassemblies.

C)for subassemblies that are immediately consumed in the next stage of production.

D)when due dates have not been calculated.

A)to group small,loose parts together.

B)when the product is manufactured in major subassemblies.

C)for subassemblies that are immediately consumed in the next stage of production.

D)when due dates have not been calculated.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

40

Effective capacity is determined by multiplying the rated capacity by utilization and efficiency.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

41

Which of the following is not a major input into capacity requirements planning (CRP)?

A)planned order releases

B)routing file

C)load profiles for each work center

D)open orders file

A)planned order releases

B)routing file

C)load profiles for each work center

D)open orders file

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

42

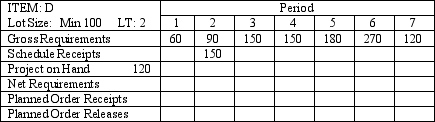

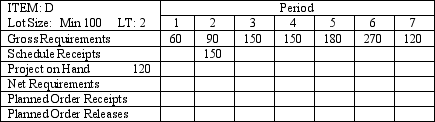

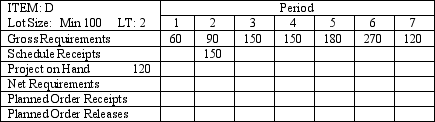

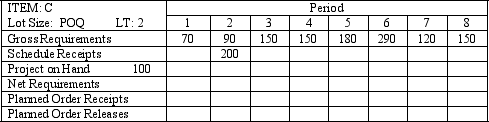

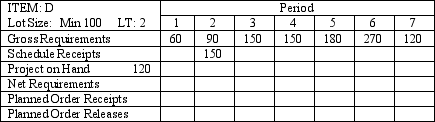

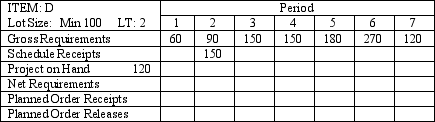

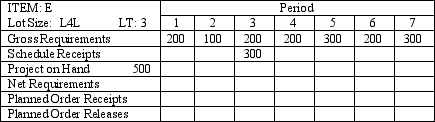

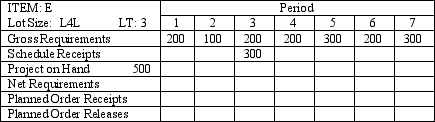

Given the following MRP matrix for Item D:

The projected on hand quantity at the end of period 3 would be

A)0

B)20

C)60

D)70

The projected on hand quantity at the end of period 3 would be

A)0

B)20

C)60

D)70

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

43

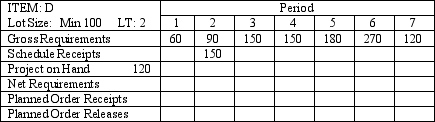

Given the following MRP matrix for Item D:

The planned order receipt for period 6 would be

A)100

B)120

C)160

D)270

The planned order receipt for period 6 would be

A)100

B)120

C)160

D)270

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

44

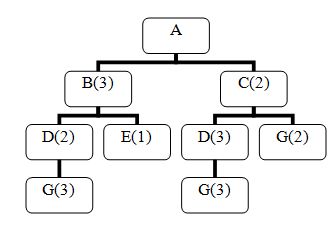

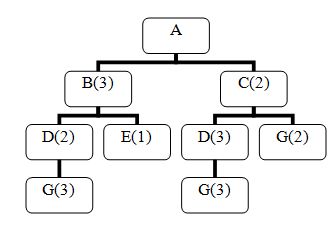

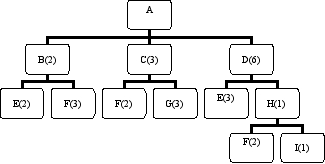

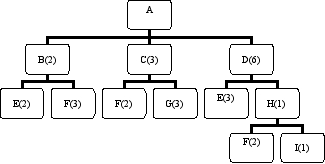

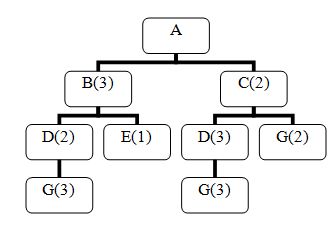

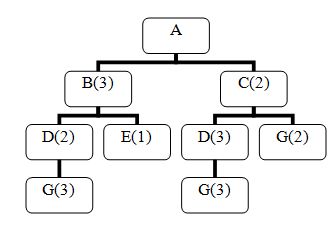

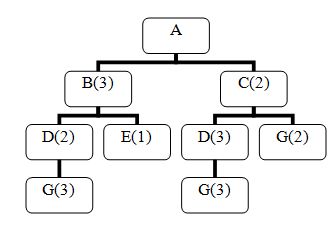

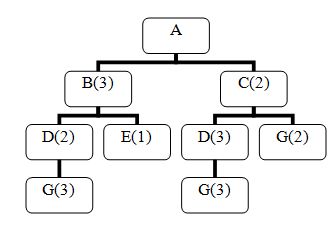

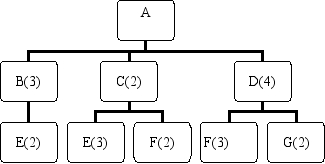

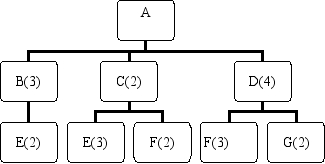

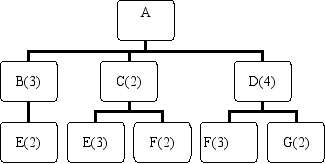

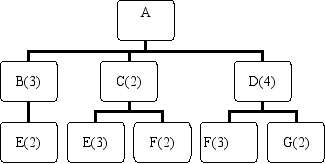

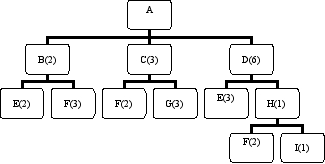

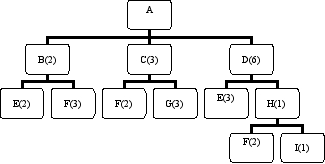

Given the following Product Structure Record

The number of D's required for each A would be

A)2

B)3

C)6

D)12

The number of D's required for each A would be

A)2

B)3

C)6

D)12

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

45

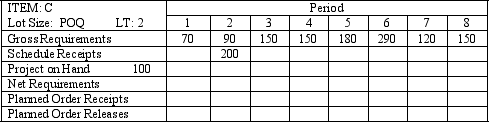

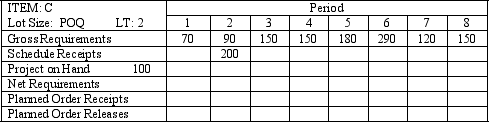

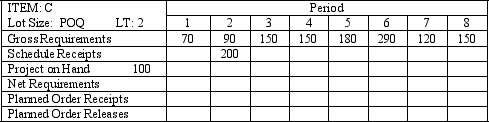

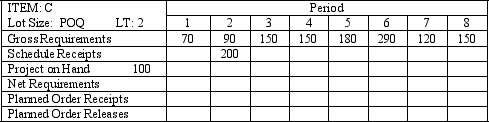

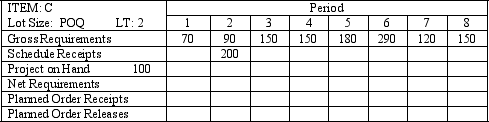

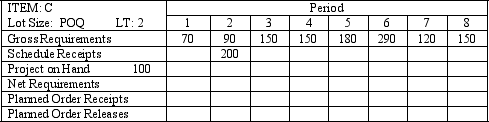

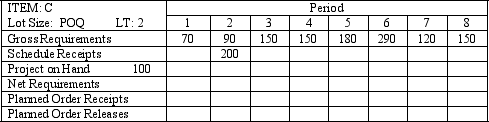

Given the following MRP matrix for Item C:

If each order cost $500 and the holding cost is $0.75 per item per period,then using the Periodic Order Quantity lot sizing technique,the Planned Order Release for period 1 would be

A)270

B)290

C)340

D)560

If each order cost $500 and the holding cost is $0.75 per item per period,then using the Periodic Order Quantity lot sizing technique,the Planned Order Release for period 1 would be

A)270

B)290

C)340

D)560

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

46

______________ is a lot sizing technique that orders for multiple demand periods is referred to as

A)Lot-for-lot (L4L)

B)Periodic order quantity (POQ)

C)Economic order quantity(EOQ)

D)Multiple order quantity (MOQ)

A)Lot-for-lot (L4L)

B)Periodic order quantity (POQ)

C)Economic order quantity(EOQ)

D)Multiple order quantity (MOQ)

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

47

Given the following MRP matrix for Item C:

If each order cost $500 and the holding cost is $0.75 per item per period,then using the Periodic Order Quantity lot sizing technique,the Projected on Hand at the end of period 7 would be

A)330

B)270

C)0

D)140

If each order cost $500 and the holding cost is $0.75 per item per period,then using the Periodic Order Quantity lot sizing technique,the Projected on Hand at the end of period 7 would be

A)330

B)270

C)0

D)140

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

48

Given the following Product Structure Record

The number of I's required for each A would be

A)1

B)2

C)6

D)12

The number of I's required for each A would be

A)1

B)2

C)6

D)12

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

49

Given the following Product Structure Record

The number of E's required for each A would be

A)1

B)2

C)3

D)4

The number of E's required for each A would be

A)1

B)2

C)3

D)4

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

50

All of the following can be used for underloaded conditions except

A)acquiring additional work.

B)pushing work back.

C)pulling work ahead.

D)reducing normal capacity.

A)acquiring additional work.

B)pushing work back.

C)pulling work ahead.

D)reducing normal capacity.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

51

Given the following MRP matrix for Item C:

If each order cost $500 and the holding cost is $0.75 per item per period,the periodic order quantity would be

A)3 periods of requirements

B)2 periods of requirements

C)1 period of requirements

D)0 period of requirements

If each order cost $500 and the holding cost is $0.75 per item per period,the periodic order quantity would be

A)3 periods of requirements

B)2 periods of requirements

C)1 period of requirements

D)0 period of requirements

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

52

The item master file contains all the following except

A)on-hand quantities.

B)lead times.

C)planned order releases.

D)on-order quantities.

A)on-hand quantities.

B)lead times.

C)planned order releases.

D)on-order quantities.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

53

Which of the following would not be used for an overloaded condition?

A)pulling work ahead

B)rerouting jobs to alternative work centers

C)pushing work back

D)splitting lots between two or more machines

A)pulling work ahead

B)rerouting jobs to alternative work centers

C)pushing work back

D)splitting lots between two or more machines

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

54

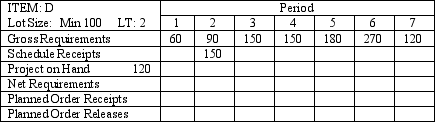

Given the following MRP matrix for Item D:

The planned order release for period 3 would be

A)100

B)160

C)270

D)300

The planned order release for period 3 would be

A)100

B)160

C)270

D)300

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

55

The MRP process of subtracting on-hand quantities and scheduled receipts from gross requirements to produce net requirements is referred to as

A)cycle counting.

B)lot sizing.

C)exploding.

D)netting.

A)cycle counting.

B)lot sizing.

C)exploding.

D)netting.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

56

A load profile compares

A)requirements for all lower-level items to higher-level items.

B)cumulative lead times to projected lead times.

C)the quantities in which items should be produced to actual demand.

D)released and planned orders with work center capacity.

A)requirements for all lower-level items to higher-level items.

B)cumulative lead times to projected lead times.

C)the quantities in which items should be produced to actual demand.

D)released and planned orders with work center capacity.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

57

Given the following Product Structure Record

The number of G's required for each A would be

A)40

B)20

C)18

D)3

The number of G's required for each A would be

A)40

B)20

C)18

D)3

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

58

Given the following MRP matrix for Item C:

If each order cost $500 and the holding cost is $0.75 per item per period,then using the Periodic Order Quantity lot sizing technique,the Planned Order Release for period 4 would be

A)270

B)290

C)340

D)560

If each order cost $500 and the holding cost is $0.75 per item per period,then using the Periodic Order Quantity lot sizing technique,the Planned Order Release for period 4 would be

A)270

B)290

C)340

D)560

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

59

The MRP process of determining requirements for lower level items based on the master production schedule is referred to as

A)lot sizing.

B)netting.

C)backward scheduling.

D)exploding.

A)lot sizing.

B)netting.

C)backward scheduling.

D)exploding.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

60

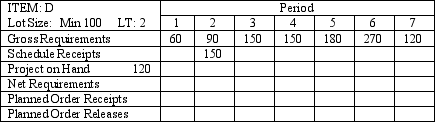

Given the following MRP matrix for Item D:

The planned order release for period 5 would be

A)100

B)120

C)160

D)270

The planned order release for period 5 would be

A)100

B)120

C)160

D)270

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

61

Given the following Product Structure Record

The number of E's required for each A would be

A)3

B)6

C)12

D)24

The number of E's required for each A would be

A)3

B)6

C)12

D)24

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

62

When is it appropriate to use material requirements planning (MRP)?

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

63

Given the following Product Structure Record

The number of G's required to assemble 10 A's would be

A)9

B)10

C)90

D)180

The number of G's required to assemble 10 A's would be

A)9

B)10

C)90

D)180

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

64

What is a bill-of-material?

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

65

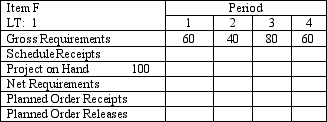

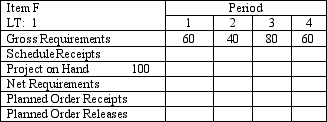

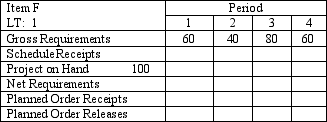

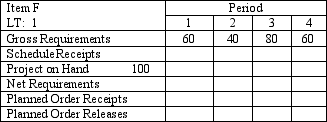

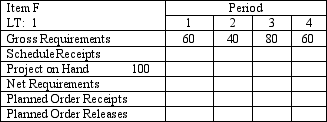

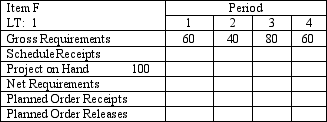

A firm has the following gross requirements for Item F.If ordering costs are $60 per order and carrying costs are $0.50 per period.

If EOQ lot sizing is used to set the minimum order quantity,then the planned order releases would be

A)40 in period 1 and 0 in period 3

B)0 in period 2 and 80 in period 3

C)120 in period 2 and 120 in period 3

D)100 in period 2 and 100 in period 3

If EOQ lot sizing is used to set the minimum order quantity,then the planned order releases would be

A)40 in period 1 and 0 in period 3

B)0 in period 2 and 80 in period 3

C)120 in period 2 and 120 in period 3

D)100 in period 2 and 100 in period 3

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

66

A firm has the following gross requirements for Item F.If ordering costs are $60 per order and carrying costs are $0.50 per period.

If EOQ lot sizing is used to set the minimum order quantity,then the projected on hand quantity at the end of period 3 would be

A)40

B)0

C)100

D)20

If EOQ lot sizing is used to set the minimum order quantity,then the projected on hand quantity at the end of period 3 would be

A)40

B)0

C)100

D)20

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

67

What is the difference between independent and dependent demand?

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

68

A firm has the following gross requirements for Item F.If ordering costs are $60 per order and carrying costs are $0.50 per period.

If EOQ lot sizing is used the minimum order quantity would be

A)85

B)100

C)120

D)150

If EOQ lot sizing is used the minimum order quantity would be

A)85

B)100

C)120

D)150

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

69

What is the master production schedule (MPS)and what role does in play in the material requirements planning (MRP)process?

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

70

A firm has the following gross requirements for Item F.If ordering costs are $60 per order and carrying costs are $0.50 per period.

If L4L ordering is used the planned order releases would be

A)40 in period 1 and 0 in period 3

B)80 in period 2 and 60 in period 3

C)60 in period 2 and 80 in period 3

D)0 in period 1 and 40 in period 3

If L4L ordering is used the planned order releases would be

A)40 in period 1 and 0 in period 3

B)80 in period 2 and 60 in period 3

C)60 in period 2 and 80 in period 3

D)0 in period 1 and 40 in period 3

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

71

A firm has the following gross requirements for Item F.If ordering costs are $60 per order and carrying costs are $0.50 per period.

If the periodic order quantity lot sizing rule is used,the number of periods worth of requirements would be

A)0

B)1

C)2

D)3

If the periodic order quantity lot sizing rule is used,the number of periods worth of requirements would be

A)0

B)1

C)2

D)3

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

72

Given the following Product Structure Record

The number of G's required for each A would be

A)2

B)8

C)12

D)24

The number of G's required for each A would be

A)2

B)8

C)12

D)24

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

73

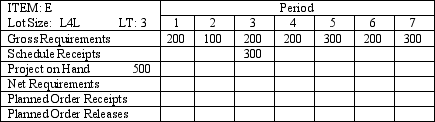

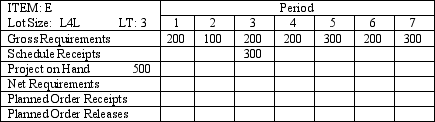

Given the following MRP matrix for Item E:

The projected on hand quantity at the end of period 3 would be

A)0

B)100

C)300

D)500

The projected on hand quantity at the end of period 3 would be

A)0

B)100

C)300

D)500

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

74

A firm has the following gross requirements for Item F.If ordering costs are $60 per order and carrying costs are $0.50 per period.

If the periodic order quantity lot sizing rule is used,then planned order releases in Period 2 would be

A)40 in period 1

B)60 in period 2

C)120 in period 3

D)140 in Period 2

If the periodic order quantity lot sizing rule is used,then planned order releases in Period 2 would be

A)40 in period 1

B)60 in period 2

C)120 in period 3

D)140 in Period 2

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

75

How does MRP differ from traditional inventory control systems?

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

76

Given the following MRP matrix for Item E:

The planned order releases for period 1 would be

A)300

B)200

C)75

D)0

The planned order releases for period 1 would be

A)300

B)200

C)75

D)0

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

77

Given the following MRP matrix for Item E:

The planned order releases for period 3 would be

A)300

B)200

C)75

D)0

The planned order releases for period 3 would be

A)300

B)200

C)75

D)0

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

78

Given the following Product Structure Record

The number of F's required for each A would be

A)6

B)12

C)18

D)24

The number of F's required for each A would be

A)6

B)12

C)18

D)24

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

79

Given the following Product Structure Record

The number of F's required for each A would be

A)2

B)3

C)12

D)16

The number of F's required for each A would be

A)2

B)3

C)12

D)16

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck

80

Given the following MRP matrix for Item E:

The planned order releases for period 4 would be

A)300

B)200

C)75

D)0

The planned order releases for period 4 would be

A)300

B)200

C)75

D)0

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 82 في هذه المجموعة.

فتح الحزمة

k this deck