Deck 20: Material Requirements Planning and Enterprise Resource Planning

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

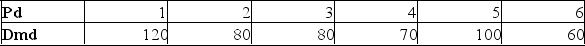

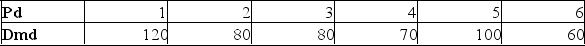

سؤال

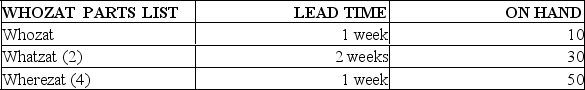

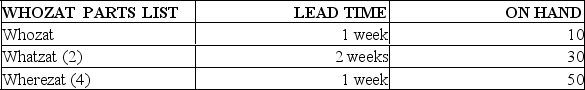

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

سؤال

فتح الحزمة

قم بالتسجيل لفتح البطاقات في هذه المجموعة!

Unlock Deck

Unlock Deck

1/78

العب

ملء الشاشة (f)

Deck 20: Material Requirements Planning and Enterprise Resource Planning

1

The term pegging refers to identifying the parent items that have generated a given set of requirements for a part or subassembly.

True

2

A bill of material contains a listing of all the raw materials,parts,and subassemblies needed to produce one unit of an end item.

True

3

Independent demand tends to be more sporadic or "lumpy" than dependent demand.

False

4

MRP requires information on inventory on hand,open orders and lead times and purchase orders for each item in stock.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

5

The MRP requires a list of the individual parts that will be converted to finished goods.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

6

An assembly-time chart indicates gross and net requirements.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

7

The planning horizon for the master production schedule (MPS)should cover or be longer than the cumulative lead time necessary to produce the end items.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

8

Dependent demand tends to be intermittent,whereas independent demand tends to be more stable.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

9

The planned-order releases at one level of an MRP plan determine the gross requirements at the next level down in the bill of material.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

10

Gross requirements for components are equal to the gross requirements of their immediate parent multiplied by the quantity per parent.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

11

MRP usually involves inventory items that have independent demand.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

12

The master production schedule (MPS)states which product components are to be produced.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

13

The master production schedule (MPS)states which end items are to be produced.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

14

A phantom bill is a special type of bill of material that is a combination of the bill of materials for a number of subassemblies.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

15

A master production schedule (MPS)is the principal output developed from MRP systems.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

16

Dependent demand is derived demand.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

17

For a given component in an MRP plan,under lot-for-lot ordering,planned order sizes are equal to net requirements.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

18

The three basic inputs of MRP are: 1)the bill of material; 2)inventory on hand,open orders and lead times; and 3)planned order releases.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

19

Lumpy demand for components required for finished goods results primarily from the periodic scheduling of batch production of the goods.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

20

The bill of material contains information on lead times.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

21

Load reports of capacity may be misleading as they do not consider queuing delays.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

22

Lot-for-lot ordering in MRP provides coverage for some predetermined number of periods.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

23

MRP II is simply a label for current,more advanced versions of software applications for MRP.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

24

ERP packages are intended to fit established ways of doing business,but some modifications to business processes or the ERP software are typically required.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

25

The part-period method for lot sizing attempts to balance setup and holding costs.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

26

Load reports compare planned capacity requirements with projected capacity and availability.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

27

MRP II involves an expanded approach to production planning and scheduling than MRP.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

28

Configuring the ERP software involves reengineering established business processes to align with the ERP's procedural settings.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

29

The emergence of ERP systems was primarily because they are less complex to use than MRP systems.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

30

Load reports show capacity requirements for departments or work centres.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

31

A net-change MRP is one that involves periodically updating all aspects of an MRP system.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

32

For relatively stable situations,a net-change MRP is better suited than using regenerative MRP.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

33

A regenerative MRP is one that is updated continuously.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

34

ERP involves software that is used to manage and coordinate all the resources,information,and functions of an organization from a shared database.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

35

The part-period method for lot sizing breaks the time periods into smaller units of time to create daily or hourly production schedules.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

36

ERP systems are based on software modules for various functional areas of a business such as purchasing,production planning,and supply chain management.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

37

Safety time is sometimes used in MRP rather than safety stock.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

38

Typically the total cost of ownership (TCO)of ERP systems is clearly detailed and certain at the time a company makes the investment to acquire a system.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

39

One of the primary reports of MRP concerns changes to open orders.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

40

Fixed-interval ordering in MRP places orders that cover a predetermined number of periods.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

41

Independent demand tends to be ___________,while dependent demand tends to be __________.

A)unstable; smooth

B)unstable; stable

C)stable; lumpy

D)smooth; sawtooth

E)sawtooth; smooth

A)unstable; smooth

B)unstable; stable

C)stable; lumpy

D)smooth; sawtooth

E)sawtooth; smooth

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

42

A process designed to handle purchasing and scheduling the production of dependent-demand components is:

A)economic part-period (EPP).

B)lot-for-lot (LFL).

C)economic order quantity (EOQ).

D)material requirements planning (MRP).

E)economic run size (ERS).

A)economic part-period (EPP).

B)lot-for-lot (LFL).

C)economic order quantity (EOQ).

D)material requirements planning (MRP).

E)economic run size (ERS).

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

43

The MRP approach that immediately updates only those records directly affected by a change is referred to as a(n):

A)regenerative MRP.

B)batch-type MRP.

C)Plossl-Wright system.

D)net-change MRP.

E)gross-change MRP.

A)regenerative MRP.

B)batch-type MRP.

C)Plossl-Wright system.

D)net-change MRP.

E)gross-change MRP.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

44

In MRP,"scheduled receipts" are:

A)identical to "planned-order receipts."

B)identical to "planned-order releases."

C)open orders already scheduled to be delivered.

D)"net requirements" in a time period.

E)the same as gross requirements

A)identical to "planned-order receipts."

B)identical to "planned-order releases."

C)open orders already scheduled to be delivered.

D)"net requirements" in a time period.

E)the same as gross requirements

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

45

The input used in MRP that lists the assemblies,subassemblies,parts,and raw materials needed to produce one unit of finished product is the:

A)master production schedule.

B)bill of material.

C)inventory-records.

D)assembly-time chart.

E)net-requirements chart.

A)master production schedule.

B)bill of material.

C)inventory-records.

D)assembly-time chart.

E)net-requirements chart.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

46

Periodic updating of an MRP system to account for all changes which have occurred within a given time interval is called:

A)pegging.

B)planned order releases.

C)net-change MRP.

D)regenerative MRP.

E)exception report.

A)pegging.

B)planned order releases.

C)net-change MRP.

D)regenerative MRP.

E)exception report.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

47

Which of the following are not primary reports provided by MRP systems?

A)Planned order releases

B)Immediate order releases

C)Demand history reports

D)Changes to open orders

A)Planned order releases

B)Immediate order releases

C)Demand history reports

D)Changes to open orders

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

48

In MRP,under lot-for-lot ordering,the size of "planned-order receipts" are equal to:

A)"scheduled receipts."

B)"planned-order releases."

C)open orders already scheduled to be delivered.

D)"gross requirements."

E)the EOQ quantity

A)"scheduled receipts."

B)"planned-order releases."

C)open orders already scheduled to be delivered.

D)"gross requirements."

E)the EOQ quantity

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

49

The gross requirements of a given part or component are determined from:

A)net requirements + amount on-hand.

B)gross requirements of the immediate parent(s).

C)planned order releases of the end item.

D)net requirements of the end item.

E)planned order release of the immediate parent(s).

A)net requirements + amount on-hand.

B)gross requirements of the immediate parent(s).

C)planned order releases of the end item.

D)net requirements of the end item.

E)planned order release of the immediate parent(s).

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

50

Which one of the following is not an input in an MRP system?

A)Planned-order releases

B)Bill of materials

C)Master production schedules

D)Inventory on-hand,open orders and lead times

A)Planned-order releases

B)Bill of materials

C)Master production schedules

D)Inventory on-hand,open orders and lead times

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

51

Ignoring the possibility of safety stock requirements,which one of the following most closely describes the calculation of net requirements for an item in MRP?

A)Gross requirements - projected on-hand - scheduled receipts

B)Gross requirements - scheduled receipts

C)Gross requirements - order releases + amount on-hand

D)Gross requirements - planned order releases

E)Gross requirements - projected on-hand + planned order releases

A)Gross requirements - projected on-hand - scheduled receipts

B)Gross requirements - scheduled receipts

C)Gross requirements - order releases + amount on-hand

D)Gross requirements - planned order releases

E)Gross requirements - projected on-hand + planned order releases

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

52

The MRP input stating which end items are to be produced,when they are needed,and what quantities are needed,is the:

A)master production schedule.

B)bill-of-materials.

C)inventory-records.

D)assembly-time chart.

E)net-requirements chart.

A)master production schedule.

B)bill-of-materials.

C)inventory-records.

D)assembly-time chart.

E)net-requirements chart.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

53

Which of these products and services would be most likely to have dependent demand?

A)Automobiles

B)Frozen vegetables

C)Flowers

D)Lumber

E)Gasoline

A)Automobiles

B)Frozen vegetables

C)Flowers

D)Lumber

E)Gasoline

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

54

In MRP processing the difference between a planned-order release and the planned-order receipt is:

A)level of safety stock.

B)scheduled receipts of open orders.

C)timing as per the lead time.

D)a one is a forecast and the other is actual.

E)the level of net requirements.

A)level of safety stock.

B)scheduled receipts of open orders.

C)timing as per the lead time.

D)a one is a forecast and the other is actual.

E)the level of net requirements.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

55

Pegging is used primarily for which one of the following purposes?

A)Identifying parent items that have generated a certain set of requirements for an item.

B)Identifying the supplier of a given component.

C)Identifying the supplier of a given component's parent.

D)Periodically update material requirements as conditions change.

E)Obtaining exception reports due to periodic changes in material requirements.

A)Identifying parent items that have generated a certain set of requirements for an item.

B)Identifying the supplier of a given component.

C)Identifying the supplier of a given component's parent.

D)Periodically update material requirements as conditions change.

E)Obtaining exception reports due to periodic changes in material requirements.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

56

Which is true of a net-change MRP?

A)It is a batch-type system which is updated periodically.

B)It generates exception reports.

C)The basic production plan is modified to reflect changes as they occur.

D)It is used to authorize the execution of planned orders.

E)It indicates the amount and timing of future changes.

A)It is a batch-type system which is updated periodically.

B)It generates exception reports.

C)The basic production plan is modified to reflect changes as they occur.

D)It is used to authorize the execution of planned orders.

E)It indicates the amount and timing of future changes.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

57

ERP automates the tasks involved in performing a business process,such as order fulfilment and financial reporting.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

58

Which of the following most closely describes dependent demand?

A)Demand generated by suppliers.

B)Sales forecasts.

C)Derived demand.

D)Demands placed on suppliers by their customers.

E)Net material requirements.

A)Demand generated by suppliers.

B)Sales forecasts.

C)Derived demand.

D)Demands placed on suppliers by their customers.

E)Net material requirements.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

59

The development and application of MRP is primarily associated with two developments: (1)managers recognizing the need to differentiate between independent and dependent demand,and (2)___________.

A)increased reliance on computers for record keeping

B)development of the EOQ model

C)the need for inventory control systems

D)the emergence of ERP systems

E)accounting systems

A)increased reliance on computers for record keeping

B)development of the EOQ model

C)the need for inventory control systems

D)the emergence of ERP systems

E)accounting systems

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

60

The hierarchical diagram that depicts the subassemblies and components that are needed to produce and/or assemble a product is called a(n):

A)assembly time chart.

B)product structure tree.

C)MRP II.

D)pegging.

E)assembly diagram

A)assembly time chart.

B)product structure tree.

C)MRP II.

D)pegging.

E)assembly diagram

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

61

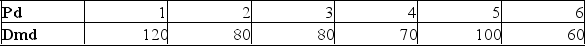

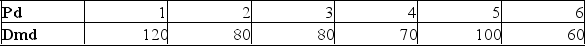

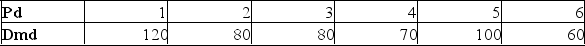

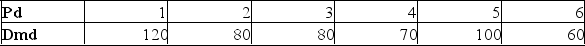

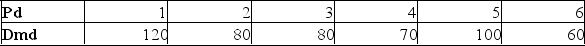

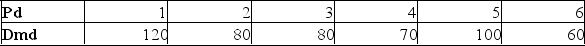

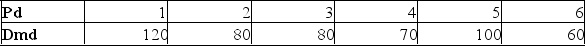

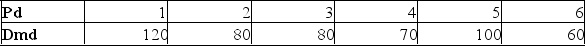

Given an order cost of $100,a,per period holding cost of $.50,and the following requirements schedule:  For which period will the second order be submitted using the part period lot sizing method?

For which period will the second order be submitted using the part period lot sizing method?

A)Period 2

B)Period 3

C)Period 4

D)Period 5

E)Period 6

For which period will the second order be submitted using the part period lot sizing method?

For which period will the second order be submitted using the part period lot sizing method?A)Period 2

B)Period 3

C)Period 4

D)Period 5

E)Period 6

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

62

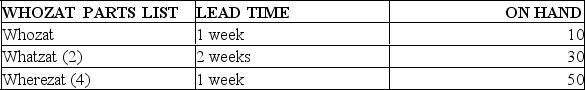

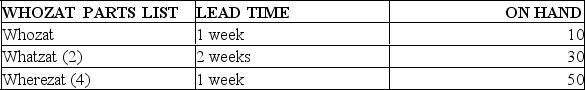

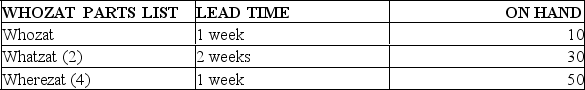

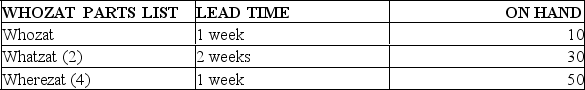

Great Product,Ltd.has just received an order for 100 Whozats,which must be ready for delivery at the start of week six.An MRP planner has prepared the following table showing product structure,lead times (orders are lot-for-lot),and quantities on hand:  How many Wherezats should be ordered?

How many Wherezats should be ordered?

A)400

B)450

C)500

D)550

E)600

How many Wherezats should be ordered?

How many Wherezats should be ordered?A)400

B)450

C)500

D)550

E)600

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

63

Under fixed-interval lot sizing,order sizes for component parts are determined based on which one of the following?

A)Gross requirements for one period.

B)Net requirements for some predetermined number of periods.

C)Economic order quantity for one period.

D)Gross requirements - net requirements for a predetermined number of periods.

E)Net requirements - amount on-hand for a predetermined number of periods.

A)Gross requirements for one period.

B)Net requirements for some predetermined number of periods.

C)Economic order quantity for one period.

D)Gross requirements - net requirements for a predetermined number of periods.

E)Net requirements - amount on-hand for a predetermined number of periods.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

64

Budget overruns when implementing ERP systems are typically caused by:

A)high equipment costs.

B)high capital interest charges.

C)the cost of the ERP software

D)high training costs

E)the software supports the companies business processes

A)high equipment costs.

B)high capital interest charges.

C)the cost of the ERP software

D)high training costs

E)the software supports the companies business processes

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

65

Given an order cost of $100,a,per period holding cost of $.50,and the following requirements schedule:  What is the lot size for the second order using the part-period method?

What is the lot size for the second order using the part-period method?

A)80

B)150

C)170

D)250

E)230

What is the lot size for the second order using the part-period method?

What is the lot size for the second order using the part-period method?A)80

B)150

C)170

D)250

E)230

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

66

Great Product,Ltd.has just received an order for 100 Whozats,which must be ready for delivery at the start of week six.An MRP planner has prepared the following table showing product structure,lead times (orders are lot-for-lot),and quantities on hand:  When should an order for Wherezats be released?

When should an order for Wherezats be released?

A)At the start of week 2.

B)At the start of week 3.

C)At the start of week 4.

D)At the start of week 5.

E)At the start of week 6.

When should an order for Wherezats be released?

When should an order for Wherezats be released?A)At the start of week 2.

B)At the start of week 3.

C)At the start of week 4.

D)At the start of week 5.

E)At the start of week 6.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

67

Great Product,Ltd.has just received an order for 100 Whozats,which must be ready for delivery at the start of week six.An MRP planner has prepared the following table showing product structure,lead times (orders are lot-for-lot),and quantities on hand:  What is the net requirement for Whatzats to fill this order?

What is the net requirement for Whatzats to fill this order?

A)100

B)140

C)150

D)180

E)200

What is the net requirement for Whatzats to fill this order?

What is the net requirement for Whatzats to fill this order?A)100

B)140

C)150

D)180

E)200

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

68

A report that compares known and expected future capacity requirements with projected available capacity is a:

A)master production schedule.

B)bill of material report.

C)inventory status report.

D)MRP schedule.

E)load report.

A)master production schedule.

B)bill of material report.

C)inventory status report.

D)MRP schedule.

E)load report.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

69

Given an order cost of $100,a,per period holding cost of $.50,and the following requirements schedule:  What is the economic part-period (EPP)for ordering this item?

What is the economic part-period (EPP)for ordering this item?

A)2

B)50

C)100

D)150

E)200

What is the economic part-period (EPP)for ordering this item?

What is the economic part-period (EPP)for ordering this item?A)2

B)50

C)100

D)150

E)200

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

70

Given an order cost of $100,a,per period holding cost of $.50,and the following requirements schedule:  What is the part-period method lot size for the order for the first period?

What is the part-period method lot size for the order for the first period?

A)120

B)200

C)280

D)350

E)450

What is the part-period method lot size for the order for the first period?

What is the part-period method lot size for the order for the first period?A)120

B)200

C)280

D)350

E)450

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

71

Given an order cost of $100,a,per period holding cost of $.50,and the following requirements schedule:  If the firm is using lot size for a fixed period of two,what is the order size for the first order?

If the firm is using lot size for a fixed period of two,what is the order size for the first order?

A)120

B)200

C)280

D)160

E)150

If the firm is using lot size for a fixed period of two,what is the order size for the first order?

If the firm is using lot size for a fixed period of two,what is the order size for the first order?A)120

B)200

C)280

D)160

E)150

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

72

The following is a list of components required to produce one unit of end item P:

P: 2 A's,3 B's,3 C's

A: 5 M's,2 R's

B: 1 D,3 N's.

C: 1 T,4 N's

M: 1 N

Determine the number of N's that will be needed to make 60 P's in each of these cases:

(i)There are currently 10 P's on hand.

(ii)On-hand inventory consists of 15 P's,10A's,20 B's,10 C's,100 N's,300 T's,and 200 M's.

P: 2 A's,3 B's,3 C's

A: 5 M's,2 R's

B: 1 D,3 N's.

C: 1 T,4 N's

M: 1 N

Determine the number of N's that will be needed to make 60 P's in each of these cases:

(i)There are currently 10 P's on hand.

(ii)On-hand inventory consists of 15 P's,10A's,20 B's,10 C's,100 N's,300 T's,and 200 M's.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

73

Given the following data,construct a material requirements plan which will result in 100 units of Parent #1 (P1)at the beginning of week 6,and 200 units of Parent #2 (P2)at the beginning of week 8:

11eab92b_c482_30a5_99e6_39a91fdebcbe

11eab92b_c482_30a5_99e6_39a91fdebcbe

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

74

Which one of the following most closely describes the MRP approach that is used for components or subassemblies to compensate for variations in lead time?

A)Pegging

B)Safety stock

C)Increased order sizes

D)Safety time

E)Low-level coding

A)Pegging

B)Safety stock

C)Increased order sizes

D)Safety time

E)Low-level coding

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

75

Which action would not be undertaken if capacity requirements planning (CRP)indicate one or more work stations are projected to be under loaded or over loaded?

A)Shifting some orders to adjacent periods.

B)Transferring employees from other areas.

C)Scheduling overtime.

D)Revise the MPS and MRP.

E)Re-run the load report using different values.

A)Shifting some orders to adjacent periods.

B)Transferring employees from other areas.

C)Scheduling overtime.

D)Revise the MPS and MRP.

E)Re-run the load report using different values.

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

76

What is the correct sequence to go from the broadest to the most detailed form of operations planning?

A)MRP » MPS » ERP

B)ERP » MRP » MPS

C)ERP » MPS » MRP

D)MPS » ERP » MRP

E)MPS » MRP » ERP

A)MRP » MPS » ERP

B)ERP » MRP » MPS

C)ERP » MPS » MRP

D)MPS » ERP » MRP

E)MPS » MRP » ERP

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

77

Which of the following are accurate statements concerning MPS,MRP and capacity requirements planning (CRP)? I)CRP is equivalent to a master production schedule (MPS).

II)CRP is needed to determine if an MPS is feasible.

III)CRP is an input to MRP.

IV)Planned-order releases from MRP are the inputs for CRP.

A)CRP is equivalent to a master production schedule (MPS).

B)CRP is an input to MRP.

C)CRP is needed to determine if an MPS is feasible

D)Planned-order releases from CRP are the inputs for MRP

II)CRP is needed to determine if an MPS is feasible.

III)CRP is an input to MRP.

IV)Planned-order releases from MRP are the inputs for CRP.

A)CRP is equivalent to a master production schedule (MPS).

B)CRP is an input to MRP.

C)CRP is needed to determine if an MPS is feasible

D)Planned-order releases from CRP are the inputs for MRP

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck

78

Given the following information,develop a material requirements plan that will yield 400 units of product P at the start of week 7.

11eab92b_c482_0992_99e6_c1c02018d3a4

11eab92b_c482_0992_99e6_c1c02018d3a4

فتح الحزمة

افتح القفل للوصول البطاقات البالغ عددها 78 في هذه المجموعة.

فتح الحزمة

k this deck