In the production of vitamin capsules,the proportion of calcium in each capsule has a specification of 48 ± 18 parts per million (ppm).An initial random sample of 100 capsules revealed a sample average calcium content of 44.5 ppm and a sample standard deviation of 3.2 ppm.Management uses  - and R-charts to monitor the calcium amount using samples each of size 4.

- and R-charts to monitor the calcium amount using samples each of size 4.

The charts depict an in-control process.The center line of the R-chart is 6.7 and the center line of the  -chart is 44.8.

-chart is 44.8.

a sample standard deviation of . Management uses - and -charts to monitor the calcium amount using samples each of size 4 .

The charts depict an in-control process. The center line of the -chart is and the center line of the -chart is .

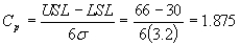

a. Compute for this process using estimates of the process mean and standard deviation derived from the random sample.

b. Compute for this process using estimates of the process mean and standard deviation derived from the control chart parameters.

c. Compute for this process using estimates of the process mean and standard deviation derived from the random sample.

c. Compute for this process using estimates of the process mean and standard deviation derived from the control chart parameters.

d. What do the differences between the values of and tell you?

Correct Answer:

Verified

b.

c.

Therefore,

View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Q91: After consolidating the types of errors

Q92: Construct a flow chart that illustrates the

Q93: Identify the tradeoffs associated with the s-chart

Q94: RM Industries wishes to monitor its end-of-week

Q95: In an attempt to solve the problem

Q97: A quality engineer took 40 samples of

Q98: What were some of the errors that

Q99: How was the problem with the third

Q100: What were the upper and lower specification

Q101: How was the

Unlock this Answer For Free Now!

View this answer and more for free by performing one of the following actions

Scan the QR code to install the App and get 2 free unlocks

Unlock quizzes for free by uploading documents