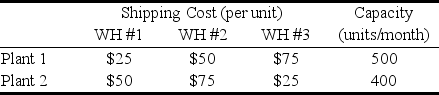

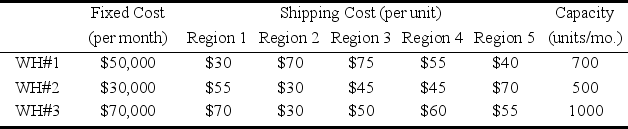

Consider a small company that produces a single product in two plants and serves customers in five different regions.The company has been using a make-to-order policy of producing the product only in the quantities needed to fill the orders that have come in from the various regions.However,because of the problems caused by the sporadic production schedule,management has decided to smooth out the production rate and ship the product to one or more storage warehouses,which then will use inventory to fill the incoming regional orders.Management now needs to decide where to locate the company's new warehouse(s).There are three locations under consideration.For each location,there is a fixed monthly cost associated with leasing and operating the warehouse there.Furthermore,each potential warehouse location has a maximum capacity for monthly shipments restricted primarily by the number of trucking docks at the site.The product costs $400 to produce at plant 1 and $300 to produce at plant 2.The shipping cost from each plant to each potential warehouse location is shown in the first table below.The fixed leasing and operating cost (if open),the shipping costs,and the capacity (maximum monthly shipments)of each potential warehouse location are shown in the second table below.The monthly demand in each of the customer regions is expected to be 200,225,100,150,and 175 units,respectively.Formulate and solve a BIP model in a spreadsheet to determine which warehouse(s)should be used and how the product should be distributed from plant to warehouse(s)to customer.  Shipping Costs and Capacity of the Plants

Shipping Costs and Capacity of the Plants  Fixed Cost,Shipping Costs,and Capacity of the Warehouses

Fixed Cost,Shipping Costs,and Capacity of the Warehouses

Correct Answer:

Verified

View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Unlock this Answer For Free Now!

View this answer and more for free by performing one of the following actions

Scan the QR code to install the App and get 2 free unlocks

Unlock quizzes for free by uploading documents