Cornerstones of Cost Accounting 1st Edition by Don Hansen,Maryanne Mowen

النسخة 1الرقم المعياري الدولي: 978-0538736787

Cornerstones of Cost Accounting 1st Edition by Don Hansen,Maryanne Mowen

النسخة 1الرقم المعياري الدولي: 978-0538736787 تمرين 42

BACKFLUSH COSTING, CONVERSION RATE

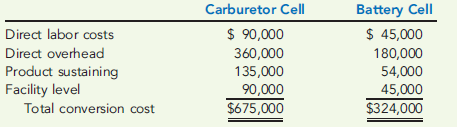

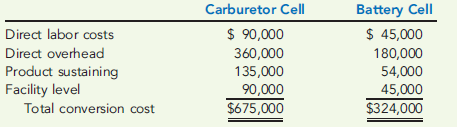

Gee Company has implemented a JIT flexible manufacturing system. Gary Polson, controller of the company, has decided to reduce the accounting requirements given the expectation of lower inventories. For one thing, he has decided to treat direct labor cost as a part of overhead and to discontinue the detailed direct labor accounting of the past. The company has created two manufacturing cells, each capable of producing a family of products: the carburetor cell and the battery cell. The output of both cells is sold to a sister division and to customers who use the batteries and carburetors for repair activity. Product-level overhead costs outside the cells are assigned to each cell using appropriate drivers. Facility-level costs are allocated to each cell on the basis of square footage. The budgeted direct labor and overhead costs are as follows:

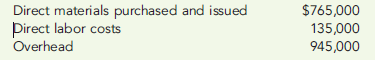

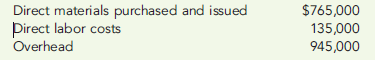

The predetermined conversion cost rate is based on available production hours in each cell. The carburetor cell has 22,500 hours available for production, and the battery cell has 13,500 hours. Conversion costs are applied to the units produced by multiplying the conversion rate by the actual time required to produce the units. The carburetor cell produced 40,500 units, taking 0.5 hour to produce one unit of product (on average). The battery cell produced 45,000 units, taking 0.25 hour to produce one unit of product (on average). Other actual results for the year are as follows:

All units produced were sold. Any conversion cost variance is closed to Cost of Goods Sold.

Required:

1. Calculate the predetermined conversion cost rates for each cell.

2. Prepare journal entries using backflush accounting. Assume two trigger points, with completion of goods as the second trigger point.

3. Repeat Requirement 2, assuming that the second trigger point is the sale of the goods.

4. Explain why there is no need to have a work-in-process inventory account.

5. Two variants of backflush costing were presented in which each used two trigger points, with the second trigger point differing. Suppose that the only trigger point for recognizing manufacturing costs occurs when the goods are sold. How would the entries be listed here? When would this backflush variant be considered appropriate?

Gee Company has implemented a JIT flexible manufacturing system. Gary Polson, controller of the company, has decided to reduce the accounting requirements given the expectation of lower inventories. For one thing, he has decided to treat direct labor cost as a part of overhead and to discontinue the detailed direct labor accounting of the past. The company has created two manufacturing cells, each capable of producing a family of products: the carburetor cell and the battery cell. The output of both cells is sold to a sister division and to customers who use the batteries and carburetors for repair activity. Product-level overhead costs outside the cells are assigned to each cell using appropriate drivers. Facility-level costs are allocated to each cell on the basis of square footage. The budgeted direct labor and overhead costs are as follows:

The predetermined conversion cost rate is based on available production hours in each cell. The carburetor cell has 22,500 hours available for production, and the battery cell has 13,500 hours. Conversion costs are applied to the units produced by multiplying the conversion rate by the actual time required to produce the units. The carburetor cell produced 40,500 units, taking 0.5 hour to produce one unit of product (on average). The battery cell produced 45,000 units, taking 0.25 hour to produce one unit of product (on average). Other actual results for the year are as follows:

All units produced were sold. Any conversion cost variance is closed to Cost of Goods Sold.

Required:

1. Calculate the predetermined conversion cost rates for each cell.

2. Prepare journal entries using backflush accounting. Assume two trigger points, with completion of goods as the second trigger point.

3. Repeat Requirement 2, assuming that the second trigger point is the sale of the goods.

4. Explain why there is no need to have a work-in-process inventory account.

5. Two variants of backflush costing were presented in which each used two trigger points, with the second trigger point differing. Suppose that the only trigger point for recognizing manufacturing costs occurs when the goods are sold. How would the entries be listed here? When would this backflush variant be considered appropriate?

التوضيح

1.

Calculation of predetermined convers...

Cornerstones of Cost Accounting 1st Edition by Don Hansen,Maryanne Mowen

لماذا لم يعجبك هذا التمرين؟

أخرى 8 أحرف كحد أدنى و 255 حرفاً كحد أقصى

حرف 255