Contemporary Engineering Economics 6th Edition by Chan Park

النسخة 6الرقم المعياري الدولي: 978-0134105598

Contemporary Engineering Economics 6th Edition by Chan Park

النسخة 6الرقم المعياري الدولي: 978-0134105598 تمرين 24

In 2 × 4 and 2 × 6 lumber production, significant amounts of wood are present in sideboards produced after the initial cutting of logs. Instead of processing the sideboards into wood chips for the paper mill, the Union Camp Company uses an "edger" to reclaim additional lumber, resulting in savings for the company. An edger is capable of reclaiming lumber by any of the following three methods: (1) removing rough edges, (2) splitting large sideboards, and (3) salvaging 2 × 4 lumber from low-quality 4 × 4 boards. Union Camp Company's engineers have discovered that a significant reduction in production costs could be achieved simply by replacing the original edger with a newer, laser-controlled model.

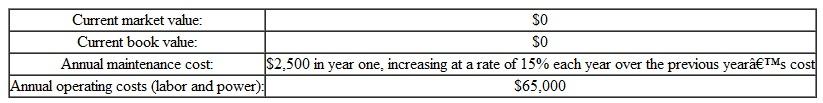

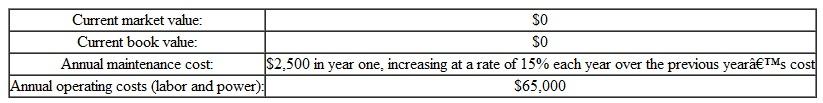

The old edger was placed in service 12 years ago and is fully depreciated. Any machine scrap value would offset the removal cost of the equipment. No market exists for this obsolete equipment. The old edger needs two operators. During the cutting operation, the operator makes edger settings, using his or her judgment. The operator has no means of determining exactly what dimension of lumber could be recovered from a given sideboard and must guess at the proper setting to recover the highest grade of lumber. Furthermore, the old edger is not capable of salvaging good-quality 2 × 4's from poor-quality 4 × 4's. The defender can continue in service for another five years with proper maintenance. The following are the financial data for the old edger:

TABLE ST 14.3

TABLE ST 14.3

The new edger has numerous advantages over its defender, including laser beams that indicate where cuts should be made to obtain the maximum yield. The new edger requires a single operator. Labor savings will be reflected in lower operating and maintenance costs of $35,000 a year. Table gives the estimated costs and the depreciation methods associated with the new edger.

The new edger has numerous advantages over its defender, including laser beams that indicate where cuts should be made to obtain the maximum yield. The new edger requires a single operator. Labor savings will be reflected in lower operating and maintenance costs of $35,000 a year. Table gives the estimated costs and the depreciation methods associated with the new edger.

Twenty-five percent of the total mill volume passes through the edger. A 12% improvement in yield is expected to be realized with the new edger, resulting in an improvement of (0.25)(0.12) = 3% in the total mill volume. The annual savings due to the improvement in productivity is thus expected to be $57,895.

(a) Should the defender be replaced now if the mill's MARR and marginal tax rate are 16% and 40%, respectively

(b) If the defender will eventually be replaced by the current challenger, when is the optimal time to perform the replacement

The old edger was placed in service 12 years ago and is fully depreciated. Any machine scrap value would offset the removal cost of the equipment. No market exists for this obsolete equipment. The old edger needs two operators. During the cutting operation, the operator makes edger settings, using his or her judgment. The operator has no means of determining exactly what dimension of lumber could be recovered from a given sideboard and must guess at the proper setting to recover the highest grade of lumber. Furthermore, the old edger is not capable of salvaging good-quality 2 × 4's from poor-quality 4 × 4's. The defender can continue in service for another five years with proper maintenance. The following are the financial data for the old edger:

TABLE ST 14.3

TABLE ST 14.3  The new edger has numerous advantages over its defender, including laser beams that indicate where cuts should be made to obtain the maximum yield. The new edger requires a single operator. Labor savings will be reflected in lower operating and maintenance costs of $35,000 a year. Table gives the estimated costs and the depreciation methods associated with the new edger.

The new edger has numerous advantages over its defender, including laser beams that indicate where cuts should be made to obtain the maximum yield. The new edger requires a single operator. Labor savings will be reflected in lower operating and maintenance costs of $35,000 a year. Table gives the estimated costs and the depreciation methods associated with the new edger.Twenty-five percent of the total mill volume passes through the edger. A 12% improvement in yield is expected to be realized with the new edger, resulting in an improvement of (0.25)(0.12) = 3% in the total mill volume. The annual savings due to the improvement in productivity is thus expected to be $57,895.

(a) Should the defender be replaced now if the mill's MARR and marginal tax rate are 16% and 40%, respectively

(b) If the defender will eventually be replaced by the current challenger, when is the optimal time to perform the replacement

التوضيح

The fourteenth chapter in the textbook a...

Contemporary Engineering Economics 6th Edition by Chan Park

لماذا لم يعجبك هذا التمرين؟

أخرى 8 أحرف كحد أدنى و 255 حرفاً كحد أقصى

حرف 255