Deck 5: Capacity Management

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Unlock Deck

Sign up to unlock the cards in this deck!

Unlock Deck

Unlock Deck

1/43

Play

Full screen (f)

Deck 5: Capacity Management

1

A work center consists of 3 machines each working a 16-hour day for 5 days a week. What is the weekly available time?

Available time: It can be defined as the number of hours that could be used in a workstation. It depends upon the number of working machines, allocated workforce, and hours of operation in a week.

Consider the following information in the workstation:

Number of machines = 3 machines

Each machine works (hours per day) =16 hours a day

Number of working days in a week = 5 working days in a week.

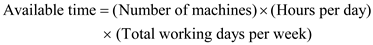

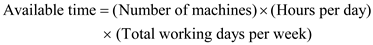

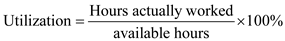

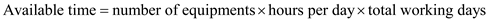

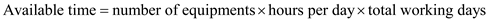

Calculate the weekly available time taken by all three machines using the following formula: …… (1)

…… (1)

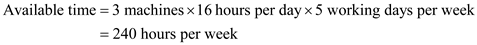

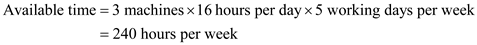

Substitute the values in the equation (1) Therefore, the weekly available time for a work center, consisting 3 machines, 16 daily hours and 5 working days a week is 240 hours per week.

Therefore, the weekly available time for a work center, consisting 3 machines, 16 daily hours and 5 working days a week is 240 hours per week.

Consider the following information in the workstation:

Number of machines = 3 machines

Each machine works (hours per day) =16 hours a day

Number of working days in a week = 5 working days in a week.

Calculate the weekly available time taken by all three machines using the following formula:

…… (1)

…… (1)Substitute the values in the equation (1)

Therefore, the weekly available time for a work center, consisting 3 machines, 16 daily hours and 5 working days a week is 240 hours per week.

Therefore, the weekly available time for a work center, consisting 3 machines, 16 daily hours and 5 working days a week is 240 hours per week. 2

What are the responsibilities of capacity management?

Capacity is the rate of work that can be carried out in a particular time period. Capacity is the ability of an employee or labor, appliance, work center, plant, or business to produce output for a particular time period.

Capacity management is the authority for deciding the ability required to accomplish the preference plans along with providing, examining and controlling the ability so the preference plan can be fulfilled.

Responsibilities of capacity management :

(1) Capacity management is responsible for confirming the capacity management tools and procedures for efficient automation work.

(2) Capacity management has drawn up capacity plans related to every stage of service decided.

(3) Capacity management is responsible for managing and justifying demand for products and services.

(4) Capacity management should act as a proficient and consultant on all capacity and performance issues and requirements.

Capacity management is the authority for deciding the ability required to accomplish the preference plans along with providing, examining and controlling the ability so the preference plan can be fulfilled.

Responsibilities of capacity management :

(1) Capacity management is responsible for confirming the capacity management tools and procedures for efficient automation work.

(2) Capacity management has drawn up capacity plans related to every stage of service decided.

(3) Capacity management is responsible for managing and justifying demand for products and services.

(4) Capacity management should act as a proficient and consultant on all capacity and performance issues and requirements.

3

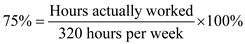

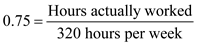

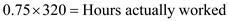

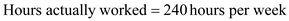

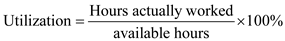

The work center in problem is utilized 75% of the time. What are the hours per week actually worked?

Calculate hours per week actually worked:

Utilization is the percentage of time that work place is active and matched up to the available time. Utilization is a scale of how exclusively a resource is being used to manufacture goods and services.

Analysis:

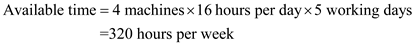

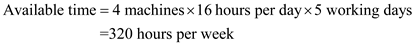

In a work station there are 4 machines. Each machine works for 16 hours a day. There are 5 working days in a week. The utilization of time is 75 percent. Using formula of utilization, estimate hours per week actually worked. From problem 1:

From problem 1:

In a work station, there are 4 machines. Each machine works 16 hours per day. There are 5 working days in a week. Calculate the weekly hours taken by all four machines. Following formula is used to calculate available time. By substituting the values,

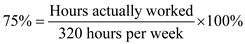

By substituting the values,  Substitute, 75 percent as utilization and 320 as hours available per week. We have to calculate hours per week actually worked.

Substitute, 75 percent as utilization and 320 as hours available per week. We have to calculate hours per week actually worked.

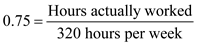

…… (Divided by 100 both side)

…… (Divided by 100 both side)  …… (Cross multiplication)

…… (Cross multiplication)  Conclusion:

Conclusion:

If the utilization capacity of 4 machines is 75 percent and total hours available is 320 hours per week, then actual worked hours per week is 240 hours per week.

Utilization is the percentage of time that work place is active and matched up to the available time. Utilization is a scale of how exclusively a resource is being used to manufacture goods and services.

Analysis:

In a work station there are 4 machines. Each machine works for 16 hours a day. There are 5 working days in a week. The utilization of time is 75 percent. Using formula of utilization, estimate hours per week actually worked.

From problem 1:

From problem 1: In a work station, there are 4 machines. Each machine works 16 hours per day. There are 5 working days in a week. Calculate the weekly hours taken by all four machines. Following formula is used to calculate available time.

By substituting the values,

By substituting the values,  Substitute, 75 percent as utilization and 320 as hours available per week. We have to calculate hours per week actually worked.

Substitute, 75 percent as utilization and 320 as hours available per week. We have to calculate hours per week actually worked.

…… (Divided by 100 both side)

…… (Divided by 100 both side)  …… (Cross multiplication)

…… (Cross multiplication)  Conclusion:

Conclusion: If the utilization capacity of 4 machines is 75 percent and total hours available is 320 hours per week, then actual worked hours per week is 240 hours per week.

4

What is capacity planning?

Unlock Deck

Unlock for access to all 43 flashcards in this deck.

Unlock Deck

k this deck

5

If the efficiency of the work center in problem 5.1 is 120%, what is the rated capacity of the work center?

Unlock Deck

Unlock for access to all 43 flashcards in this deck.

Unlock Deck

k this deck

6

Describe the three steps of capacity planning.

Unlock Deck

Unlock for access to all 43 flashcards in this deck.

Unlock Deck

k this deck

7

A work center consisting of 7 machines is operated 16 hours a day for a 5-day week. Utilization is 80%, and efficiency is 110%. What is the rated weekly capacity in standard hours?

Unlock Deck

Unlock for access to all 43 flashcards in this deck.

Unlock Deck

k this deck

8

Relate the three levels of priority planning to capacity planning. Describe each level in terms of the detail and the time horizons used.

Unlock Deck

Unlock for access to all 43 flashcards in this deck.

Unlock Deck

k this deck

9

A work center consists of 4 machines working 8 hours a day for a 5-day week. If the utilization is 80% and the efficiency is 90%, what is the rated capacity of the work center?

Unlock Deck

Unlock for access to all 43 flashcards in this deck.

Unlock Deck

k this deck

10

What is capacity requirements planning? At what level of the priority planning process does it occur?

Unlock Deck

Unlock for access to all 43 flashcards in this deck.

Unlock Deck

k this deck

11

Over a period of 4 weeks, a work center produced 50, 45, 42, and 52 standard hours of work. What is the demonstrated capacity of the work center?

Unlock Deck

Unlock for access to all 43 flashcards in this deck.

Unlock Deck

k this deck

12

What are the inputs to the CRP process? Where is this information obtained?

Unlock Deck

Unlock for access to all 43 flashcards in this deck.

Unlock Deck

k this deck

13

In an 11-week period, a work center produces 1050 standard hours of work. What is the measured capacity of the work center?

Unlock Deck

Unlock for access to all 43 flashcards in this deck.

Unlock Deck

k this deck

14

Describe each of the following and the information they contain.

a. Open order.

b. Routing.

c. Work center.

a. Open order.

b. Routing.

c. Work center.

Unlock Deck

Unlock for access to all 43 flashcards in this deck.

Unlock Deck

k this deck

15

In 1 week, a work center produces 75 standard hours of work. The hours scheduled are 80, and 72 hours are actually worked. Calculate the utilization and efficiency of the work center.

Unlock Deck

Unlock for access to all 43 flashcards in this deck.

Unlock Deck

k this deck

16

What is a shop calendar? Why is it needed?

Unlock Deck

Unlock for access to all 43 flashcards in this deck.

Unlock Deck

k this deck

17

A work center consisting of 3 machines operates 40 hours a week. In a 4-week period, it actually worked 355 hours and produced 475 standard hours of work. Calculate the utilization and efficiency of the work center. What is the demonstrated weekly capacity of the work center?

Unlock Deck

Unlock for access to all 43 flashcards in this deck.

Unlock Deck

k this deck

18

In which file would you find the following information?

a. A scheduled receipt.

b. A planned receipt.

c. Efficiency and utilization.

d. Sequence of operations on a part.

a. A scheduled receipt.

b. A planned receipt.

c. Efficiency and utilization.

d. Sequence of operations on a part.

Unlock Deck

Unlock for access to all 43 flashcards in this deck.

Unlock Deck

k this deck

19

A firm wishes to determine the efficiency and utilization of a work center composed of 5 machines each working 16 hours per day for 5 days a week. A study undertaken by the materials management department found that over the past 50 weeks the work center was actually working for 16,000 hours, and work performed was 15,200 standard hours. Calculate the utilization, efficiency, and demonstrated weekly capacity.

Unlock Deck

Unlock for access to all 43 flashcards in this deck.

Unlock Deck

k this deck

20

Define capacity available.What are the four factors that affect it?

Unlock Deck

Unlock for access to all 43 flashcards in this deck.

Unlock Deck

k this deck

21

How many standard hours are needed to run an order of 200 pieces if the setup time is 1.3 hours and the run time 0.3 hours per piece? How many actual hours are needed at the work center if the efficiency is 130% and the utilization is 70%?

Unlock Deck

Unlock for access to all 43 flashcards in this deck.

Unlock Deck

k this deck

22

Why is standard time usually used to measure capacity?

Unlock Deck

Unlock for access to all 43 flashcards in this deck.

Unlock Deck

k this deck

23

How many standard hours are needed to run an order of 500 pieces if the setup time is 2.0 hours and the run time 0.3 hours per piece? How many actual hours are needed at the work center if the efficiency is 110% and the utilization is 85%?

Unlock Deck

Unlock for access to all 43 flashcards in this deck.

Unlock Deck

k this deck

24

What are rated capacity, utilization, and efficiency? How are they related?

Unlock Deck

Unlock for access to all 43 flashcards in this deck.

Unlock Deck

k this deck

25

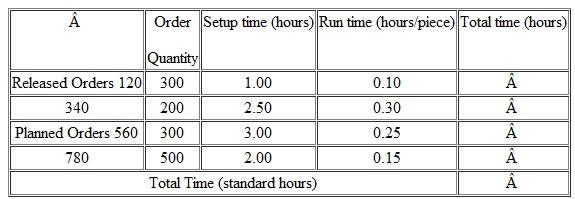

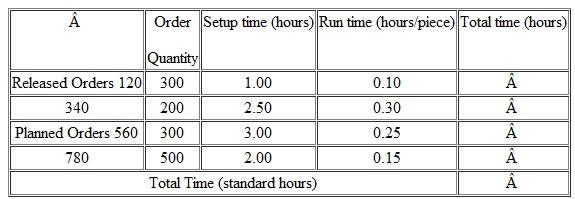

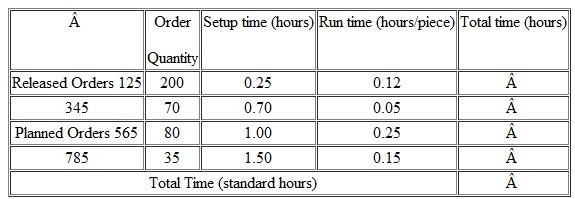

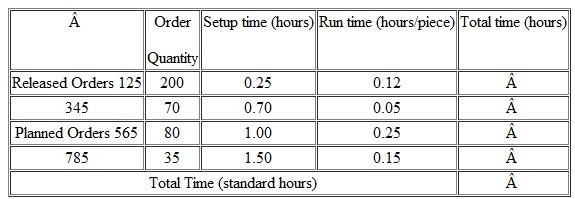

A work center has the following open and planned orders for week 4. Calculate the total standard time required (load).

Unlock Deck

Unlock for access to all 43 flashcards in this deck.

Unlock Deck

k this deck

26

What is measured or demonstrated capacity? How is it different from rated capacity?

Unlock Deck

Unlock for access to all 43 flashcards in this deck.

Unlock Deck

k this deck

27

A work center has the following open and planned orders for week 4. Calculate the total standard time required (load).

Unlock Deck

Unlock for access to all 43 flashcards in this deck.

Unlock Deck

k this deck

28

What is load?

Unlock Deck

Unlock for access to all 43 flashcards in this deck.

Unlock Deck

k this deck

29

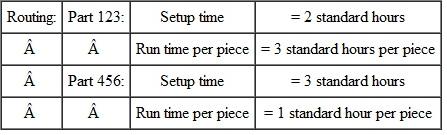

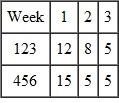

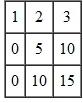

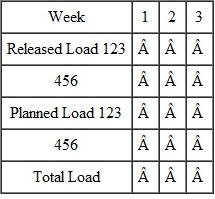

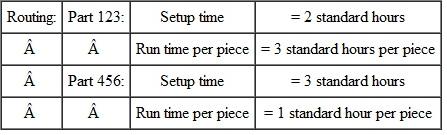

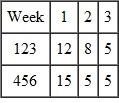

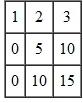

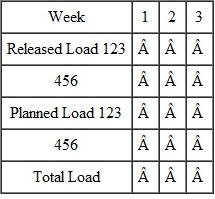

Using the information in the following route file, open order file, and MRP planned orders, calculate the load on the work center.  Open Orders for parts

Open Orders for parts  Planned Orders for parts

Planned Orders for parts  Load report

Load report

Open Orders for parts

Open Orders for parts  Planned Orders for parts

Planned Orders for parts  Load report

Load report

Unlock Deck

Unlock for access to all 43 flashcards in this deck.

Unlock Deck

k this deck

30

What is a work center load report? What information does it contain?

Unlock Deck

Unlock for access to all 43 flashcards in this deck.

Unlock Deck

k this deck

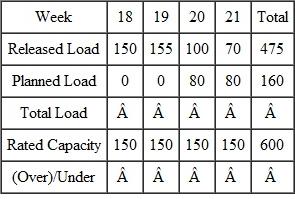

31

Complete the following load report and suggest possible courses of action.

Unlock Deck

Unlock for access to all 43 flashcards in this deck.

Unlock Deck

k this deck

32

What is a schedule?

Unlock Deck

Unlock for access to all 43 flashcards in this deck.

Unlock Deck

k this deck

33

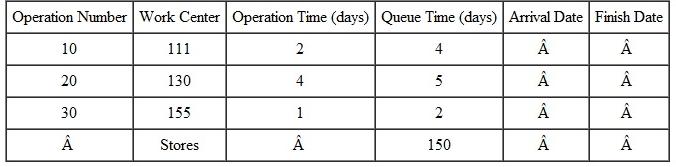

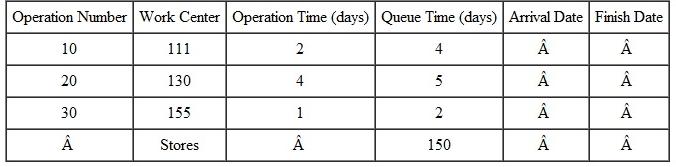

Back schedule the following shop order. All times are given in days. Move time between operations is 1 day, and wait time is 1 day. Due date is day 150. Assume orders start at the beginning of a day and finish at the end of a day.

Unlock Deck

Unlock for access to all 43 flashcards in this deck.

Unlock Deck

k this deck

34

Describe the process of back scheduling.

Unlock Deck

Unlock for access to all 43 flashcards in this deck.

Unlock Deck

k this deck

35

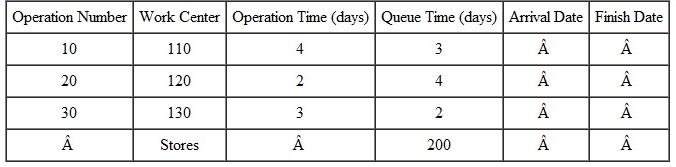

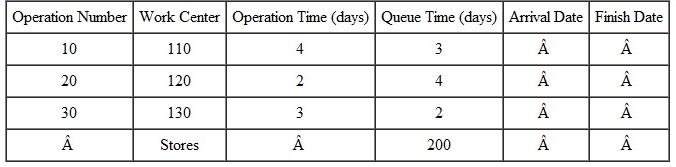

Back schedule the following shop order. All times are given in days. Move time between operations is 1 day, and wait time is 1 day. Due date is day 200. Assume orders start at the beginning of a day and finish at the end of a day.

Unlock Deck

Unlock for access to all 43 flashcards in this deck.

Unlock Deck

k this deck

36

What are the two ways of balancing capacity available and load? Which is preferred? Why?

Unlock Deck

Unlock for access to all 43 flashcards in this deck.

Unlock Deck

k this deck

37

What are some of the ways capacity available can be altered in the short run?

Unlock Deck

Unlock for access to all 43 flashcards in this deck.

Unlock Deck

k this deck

38

Why is feedback necessary in a control system?

Unlock Deck

Unlock for access to all 43 flashcards in this deck.

Unlock Deck

k this deck

39

What might be some of the problems in scheduling rated capacity too closely to the load?

Unlock Deck

Unlock for access to all 43 flashcards in this deck.

Unlock Deck

k this deck

40

How is safety capacity used?

Unlock Deck

Unlock for access to all 43 flashcards in this deck.

Unlock Deck

k this deck

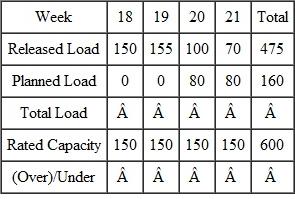

41

Discuss the nature and probable sources of the problem.

Unlock Deck

Unlock for access to all 43 flashcards in this deck.

Unlock Deck

k this deck

42

Examine the rough-cut capacity situation using the data Jason gathered. Discuss the results and how they are linked to the problems identified in question 1.

Unlock Deck

Unlock for access to all 43 flashcards in this deck.

Unlock Deck

k this deck

43

Use the information and your knowledge of the situation to develop a complete plan for Jason to use in the future. Part of this plan should be to build and demonstrate the approach to master scheduling for the data given in the case

Unlock Deck

Unlock for access to all 43 flashcards in this deck.

Unlock Deck

k this deck