Deck 19: Capital Investment

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Unlock Deck

Sign up to unlock the cards in this deck!

Unlock Deck

Unlock Deck

1/47

Play

Full screen (f)

Deck 19: Capital Investment

1

What is the accounting rate of return?

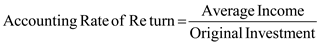

Accounting rate of return (ARR):

• The accounting rate of return (ARR) is a commonly used non-discounting model. It is also known as annual rate of return.

• Annual rate of return shows the profitability of a capital expenditure by dividing anticipated annual net income by the average investment.

• Annual rate of return is based on accrual accounting data rather than on cash flows.

• Formula for annual rate of return is below:

• The accounting rate of return (ARR) is a commonly used non-discounting model. It is also known as annual rate of return.

• Annual rate of return shows the profitability of a capital expenditure by dividing anticipated annual net income by the average investment.

• Annual rate of return is based on accrual accounting data rather than on cash flows.

• Formula for annual rate of return is below:

2

NPV: Basic Concepts

Buena Vision Clinic is considering an investment that requires an outlay of $600,000 and promises a net cash inflow one year from now of $810,000. Assume the cost of capital is 10 percent.

Required:

1. Break the $810,000 future cash inflow into three components:

a. The return of the original investment

b. The cost of capital

c. The profit earned on the investment

2. Now, compute the present value of the profit earned on the investment.

3. Compute the NPV of the investment. Compare this with the present value of the profit computed in Requirement 2. What does this tell you about the meaning of NPV?

Buena Vision Clinic is considering an investment that requires an outlay of $600,000 and promises a net cash inflow one year from now of $810,000. Assume the cost of capital is 10 percent.

Required:

1. Break the $810,000 future cash inflow into three components:

a. The return of the original investment

b. The cost of capital

c. The profit earned on the investment

2. Now, compute the present value of the profit earned on the investment.

3. Compute the NPV of the investment. Compare this with the present value of the profit computed in Requirement 2. What does this tell you about the meaning of NPV?

1. The cash flows of $810,000 include three components, the cost of capital, return on investment and profit earned. The profit earned is $210,000 and original capital is $600,000.

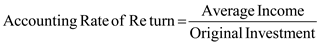

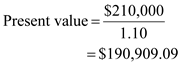

2. The present value of profit earned of $210,000 can be calculated as:

Thus, the present value of the profit earned on investment is $190,909.09.

Thus, the present value of the profit earned on investment is $190,909.09.

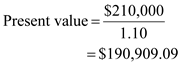

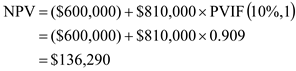

3. The net present value (NPV) is the present value of cash inflows discounted at required rate of return less the present value of cash outflows. The NPV of the project using the given annual cash flows at the required return of 10% will be:

Thus, the NPV of the project is $136,290. The value calculated in 2 part indicates the present value of profit while this is the present value of cash outflows less present value of cash inflows.

Thus, the NPV of the project is $136,290. The value calculated in 2 part indicates the present value of profit while this is the present value of cash outflows less present value of cash inflows.

2. The present value of profit earned of $210,000 can be calculated as:

Thus, the present value of the profit earned on investment is $190,909.09.

Thus, the present value of the profit earned on investment is $190,909.09.3. The net present value (NPV) is the present value of cash inflows discounted at required rate of return less the present value of cash outflows. The NPV of the project using the given annual cash flows at the required return of 10% will be:

Thus, the NPV of the project is $136,290. The value calculated in 2 part indicates the present value of profit while this is the present value of cash outflows less present value of cash inflows.

Thus, the NPV of the project is $136,290. The value calculated in 2 part indicates the present value of profit while this is the present value of cash outflows less present value of cash inflows. 3

Payback, NPV, Managerial Incentives, Ethical Behavior

Kent Tessman, manager of a Dairy Products Division, was pleased with his division's performance over the past three years. Each year, divisional profits had increased, and he had earned a sizable bonus. (Bonuses are a linear function of the division's reported income.) He had also received considerable attention from higher management. A vice president had told him in confidence that if his performance over the next three years matched his first three, he would be promoted to higher management.

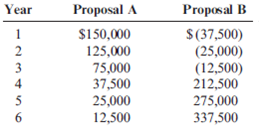

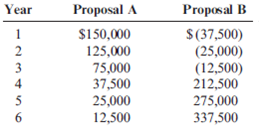

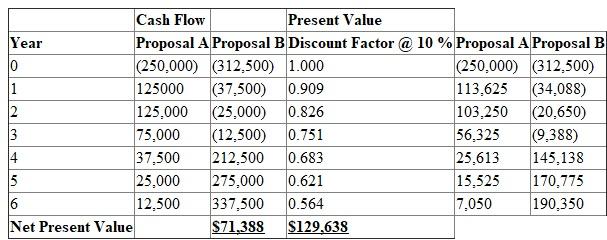

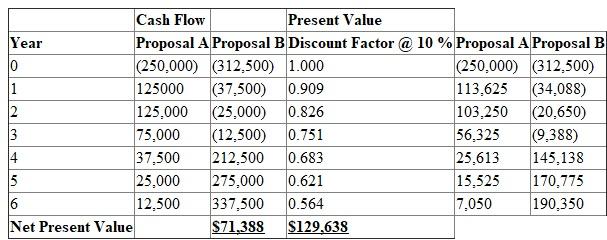

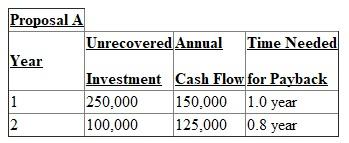

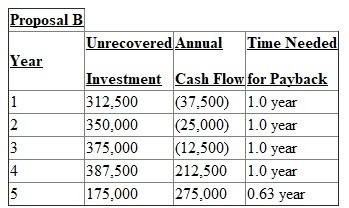

Determined to fulfill these expectations, Kent made sure that he personally reviewed every capital budget request. He wanted to be certain that any funds invested would provide good, solid returns. (The division's cost of capital is 10 percent.) At the moment, he is reviewing two independent requests. Proposal A involves automating a manufacturing operation that is currently labor intensive. Proposal B centers on developing and marketing a new ice cream product. Proposal A requires an initial outlay of $250,000, and Proposal B requires $312,500. Both projects could be funded, given the status of the division's capital budget. Both have an expected life of six years and have the following projected after-tax cash flows:

After careful consideration of each investment, Kent approved funding of Proposal A and rejected Proposal B.

Required:

1. Compute the NPV for each proposal.

2. Compute the payback period for each proposal.

3. According to your analysis, which proposal(s) should be accepted? Explain.

4. Explain why Kent accepted only Proposal A. Considering the possible reasons for rejection, would you judge his behavior to be ethical? Explain.

Kent Tessman, manager of a Dairy Products Division, was pleased with his division's performance over the past three years. Each year, divisional profits had increased, and he had earned a sizable bonus. (Bonuses are a linear function of the division's reported income.) He had also received considerable attention from higher management. A vice president had told him in confidence that if his performance over the next three years matched his first three, he would be promoted to higher management.

Determined to fulfill these expectations, Kent made sure that he personally reviewed every capital budget request. He wanted to be certain that any funds invested would provide good, solid returns. (The division's cost of capital is 10 percent.) At the moment, he is reviewing two independent requests. Proposal A involves automating a manufacturing operation that is currently labor intensive. Proposal B centers on developing and marketing a new ice cream product. Proposal A requires an initial outlay of $250,000, and Proposal B requires $312,500. Both projects could be funded, given the status of the division's capital budget. Both have an expected life of six years and have the following projected after-tax cash flows:

After careful consideration of each investment, Kent approved funding of Proposal A and rejected Proposal B.

Required:

1. Compute the NPV for each proposal.

2. Compute the payback period for each proposal.

3. According to your analysis, which proposal(s) should be accepted? Explain.

4. Explain why Kent accepted only Proposal A. Considering the possible reasons for rejection, would you judge his behavior to be ethical? Explain.

1.Calculate NPV for each proposal:

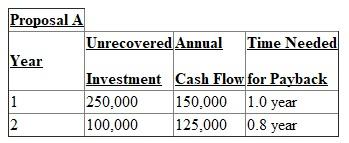

2.Calculate Payback period for each proposal:

2.Calculate Payback period for each proposal:

Payback period is 1.8 years.

Payback period is 1.8 years.

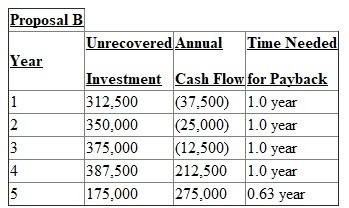

Payback period is 4.63 years.

Payback period is 4.63 years.

3.Decision:

According to our analysis, Proposal B should be accepted as it has higher NPV.

4.Kent accepted Proposal A as it entails positive cash flows over the six year period. In case his performance over the next three years matched his first three, he would be promoted to higher management.

Given this incentive, if Proposal B is accepted, which entails negative cash flows in the first three years but which as a whole increases the shareholders wealth over a six year period, would affect his promotion. The manager's behaviour of fulfilling personal goals is not ethical and is at the cost to shareholders.

2.Calculate Payback period for each proposal:

2.Calculate Payback period for each proposal:  Payback period is 1.8 years.

Payback period is 1.8 years. Payback period is 4.63 years.

Payback period is 4.63 years.3.Decision:

According to our analysis, Proposal B should be accepted as it has higher NPV.

4.Kent accepted Proposal A as it entails positive cash flows over the six year period. In case his performance over the next three years matched his first three, he would be promoted to higher management.

Given this incentive, if Proposal B is accepted, which entails negative cash flows in the first three years but which as a whole increases the shareholders wealth over a six year period, would affect his promotion. The manager's behaviour of fulfilling personal goals is not ethical and is at the cost to shareholders.

4

After-Tax Cash Flows

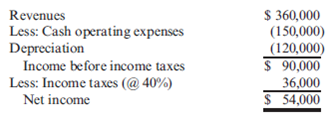

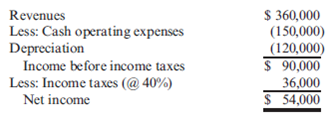

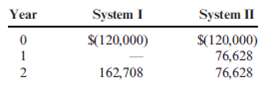

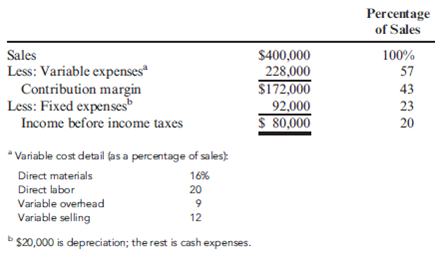

Warren Company plans to open a new repair service center for one of its electronic products. The center requires an investment in depreciable assets costing $480,000. The assets will be depreciated on a straight-line basis, over four years, and have no expected salvage value. The annual income statement for the center is given below.

Required:

1. Using the income approach, calculate the after-tax cash flows.

2. Using the decomposition approach, calculate the after-tax cash flows for each item of the income statement and show that the total is the same as the income approach.

3. What if it is desirable to express the decomposition approach in a spreadsheet format for the four years to facilitate the use of spreadsheet software packages? Express the decomposition approach in a spreadsheet format, with a column for each income item and a total column.

Warren Company plans to open a new repair service center for one of its electronic products. The center requires an investment in depreciable assets costing $480,000. The assets will be depreciated on a straight-line basis, over four years, and have no expected salvage value. The annual income statement for the center is given below.

Required:

1. Using the income approach, calculate the after-tax cash flows.

2. Using the decomposition approach, calculate the after-tax cash flows for each item of the income statement and show that the total is the same as the income approach.

3. What if it is desirable to express the decomposition approach in a spreadsheet format for the four years to facilitate the use of spreadsheet software packages? Express the decomposition approach in a spreadsheet format, with a column for each income item and a total column.

Unlock Deck

Unlock for access to all 47 flashcards in this deck.

Unlock Deck

k this deck

5

Explain what a postaudit is and how it can provide useful input for future capital investment decisions-especially those involving advanced technology.

Unlock Deck

Unlock for access to all 47 flashcards in this deck.

Unlock Deck

k this deck

6

Basic IRR Analysis

Friedman Company is considering installing a new IT system. The cost of the new system is estimated to be $2,250,0000, but it would produce after-tax savings of $450,000 per year in labor costs. The estimated life of the new system is 10 years, with no salvage value expected. Intrigued by the possibility of saving $450,000 per year and having a more reliable information system, the president of Friedman has asked for an analysis of the project's economic viability. All capital projects are required to earn at least the firm's cost of capital, which is 12 percent.

Required:

1. Calculate the project's internal rate of return. Should the company acquire the new IT system?

2. Suppose that savings are less than claimed. Calculate the minimum annual cash savings that must be realized for the project to earn a rate equal to the firm's cost of capital. Comment on the safety margin that exists, if any.

3. Suppose that the life of the IT system is overestimated by two years. Repeat Requirements 1 and 2 under this assumption. Comment on the usefulness of this information.

Friedman Company is considering installing a new IT system. The cost of the new system is estimated to be $2,250,0000, but it would produce after-tax savings of $450,000 per year in labor costs. The estimated life of the new system is 10 years, with no salvage value expected. Intrigued by the possibility of saving $450,000 per year and having a more reliable information system, the president of Friedman has asked for an analysis of the project's economic viability. All capital projects are required to earn at least the firm's cost of capital, which is 12 percent.

Required:

1. Calculate the project's internal rate of return. Should the company acquire the new IT system?

2. Suppose that savings are less than claimed. Calculate the minimum annual cash savings that must be realized for the project to earn a rate equal to the firm's cost of capital. Comment on the safety margin that exists, if any.

3. Suppose that the life of the IT system is overestimated by two years. Repeat Requirements 1 and 2 under this assumption. Comment on the usefulness of this information.

Unlock Deck

Unlock for access to all 47 flashcards in this deck.

Unlock Deck

k this deck

7

What is the cost of capital? What role does it play in capital investment decisions?

Unlock Deck

Unlock for access to all 47 flashcards in this deck.

Unlock Deck

k this deck

8

Solving for Unknowns

Consider each of the following independent cases.

Required:

1. Hal's Stunt Company is investing $120,000 in a project that will yield a uniform series of cash inflows over the next four years. If the internal rate of return is 14 percent, how much cash inflow per year can be expected?

2. Warner Medical Clinic has decided to invest in some new blood diagnostic equipment. The equipment will have a three-year life and will produce a uniform series of cash savings. The net present value of the equipment is $1,750, using a discount rate of 8 percent. The internal rate of return is 12 percent. Determine the investment and the amount of cash savings realized each year.

3. A new lathe costing $60,096 will produce savings of $12,000 per year. How many years must the lathe last if an IRR of 18 percent is realized?

4. The NPV of a new product (a new brand of candy) is $6,075. The product has a life of four years and produces the following cash flows:

The cost of the project is three times the cash flow produced in Year 4. The discount rate is 10 percent. Find the cost of the project and the cash flow for Year 4.

Consider each of the following independent cases.

Required:

1. Hal's Stunt Company is investing $120,000 in a project that will yield a uniform series of cash inflows over the next four years. If the internal rate of return is 14 percent, how much cash inflow per year can be expected?

2. Warner Medical Clinic has decided to invest in some new blood diagnostic equipment. The equipment will have a three-year life and will produce a uniform series of cash savings. The net present value of the equipment is $1,750, using a discount rate of 8 percent. The internal rate of return is 12 percent. Determine the investment and the amount of cash savings realized each year.

3. A new lathe costing $60,096 will produce savings of $12,000 per year. How many years must the lathe last if an IRR of 18 percent is realized?

4. The NPV of a new product (a new brand of candy) is $6,075. The product has a life of four years and produces the following cash flows:

The cost of the project is three times the cash flow produced in Year 4. The discount rate is 10 percent. Find the cost of the project and the cash flow for Year 4.

Unlock Deck

Unlock for access to all 47 flashcards in this deck.

Unlock Deck

k this deck

9

Replacement Decision, Computing After-Tax Cash Flows, Basic NPV Analysis

Okmulgee Hospital (a large metropolitan for-profit hospital) is considering replacing its MRI equipment with a new model manufactured by a different company. The old MRI equipment was acquired three years ago, has a remaining life of five years, and will have a salvage value of $100,000. The book value is $2,000,000. Straight-line depreciation with a half-year convention is being used for tax purposes. The cash operating costs of the existing MRI equipment total $1,000,000 per year.

The new MRI equipment has an initial cost of $5,000,000 and will have cash operating costs of $500,000 per year. The new MRI will have a life of five years and a salvage value of $1,000,000 at the end of the fifth year. MACRS depreciation will be used for tax purposes. If the new MRI equipment is purchased, the old one will be sold for $500,000. The company needs to decide whether to keep the old MRI equipment or buy the new one. The cost of capital is 12 percent. The combined federal and state tax rate is 40 percent.

Required:

Compute the NPV of each alternative. Should the company keep the old MRI equipment or buy the new one?

Okmulgee Hospital (a large metropolitan for-profit hospital) is considering replacing its MRI equipment with a new model manufactured by a different company. The old MRI equipment was acquired three years ago, has a remaining life of five years, and will have a salvage value of $100,000. The book value is $2,000,000. Straight-line depreciation with a half-year convention is being used for tax purposes. The cash operating costs of the existing MRI equipment total $1,000,000 per year.

The new MRI equipment has an initial cost of $5,000,000 and will have cash operating costs of $500,000 per year. The new MRI will have a life of five years and a salvage value of $1,000,000 at the end of the fifth year. MACRS depreciation will be used for tax purposes. If the new MRI equipment is purchased, the old one will be sold for $500,000. The company needs to decide whether to keep the old MRI equipment or buy the new one. The cost of capital is 12 percent. The combined federal and state tax rate is 40 percent.

Required:

Compute the NPV of each alternative. Should the company keep the old MRI equipment or buy the new one?

Unlock Deck

Unlock for access to all 47 flashcards in this deck.

Unlock Deck

k this deck

10

The IRR is the true or actual rate of return being earned by the project. Do you agree or disagree? Discuss.

Unlock Deck

Unlock for access to all 47 flashcards in this deck.

Unlock Deck

k this deck

11

Explain what sensitivity analysis is. How can it help in capital budgeting decisions?

Unlock Deck

Unlock for access to all 47 flashcards in this deck.

Unlock Deck

k this deck

12

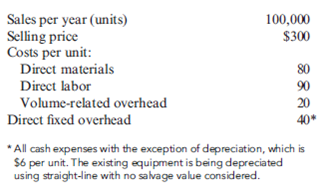

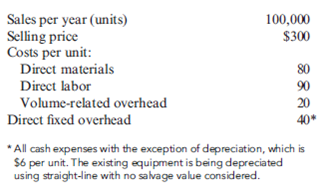

Capital Investment, Discount Rates, Intangible and Indirect Benefits, Time Horizon, Contemporary Manufacturing Environment

Mallette Manufacturing, Inc., produces washing machines, dryers, and dishwashers. Because of increasing competition, Mallette is considering investing in an automated manufacturing system. Since competition is most keen for dishwashers, the production process for this line has been selected for initial evaluation. The automated system for the dishwasher line would replace an existing system (purchased one year ago for $6 million). Although the existing system will be fully depreciated in nine years, it is expected to last another 10 years. The automated system would also have a useful life of 10 years.

The automated system will cost $34 million to purchase, plus an estimated $20 million in software and implementation. (Assume that all investment outlays occur at the beginning of the first year.) If the automated equipment is purchased, the old equipment can be sold for $3 million.

The automated system will require fewer parts for production and will produce with less waste. Because of this, the direct material cost per unit will be reduced by 25 percent. Automation will also require fewer support activities, and as a consequence, volume-related overhead will be reduced by $4 per unit and direct fixed overhead (other than depreciation) by $17 per unit. Direct labor is reduced by 60 percent. Assume, for simplicity, that the new investment will be depreciated on a pure straight-line basis for tax purposes with no salvage value. Ignore the half-life convention.

The firm's cost of capital is 12 percent, but management chooses to use 20 percent as the required rate of return for evaluation of investments. The combined federal and state tax rate is 40 percent.

Required:

1. Compute the net present value for the old system and the automated system. Which system would the company choose?

2. Repeat the net present value analysis of Requirement 1, using 12 percent as the discount rate.

3. Upon seeing the projected sales for the old system, the marketing manager commented: "Sales of 100,000 units per year cannot be maintained in the current competitive environment for more than one year unless we buy the automated system. The automated system will allow us to compete on the basis of quality and lead time. If we keep the old system, our sales will drop by 10,000 units per year." Repeat the net present value analysis, using this new information and a 12 percent discount rate.

4. An industrial engineer for Mallette noticed that salvage value for the automated equipment had not been included in the analysis. He estimated that the equipment could be sold for $4 million at the end of 10 years. He also estimated that the equipment of the old system would have no salvage value at the end of 10 years. Repeat the net present value analysis using this information, the information in Requirement 3, and a 12 percent discount rate.

5. Given the outcomes of the previous four requirements, comment on the importance of providing accurate inputs for assessing investments in automated manufacturing systems.

Mallette Manufacturing, Inc., produces washing machines, dryers, and dishwashers. Because of increasing competition, Mallette is considering investing in an automated manufacturing system. Since competition is most keen for dishwashers, the production process for this line has been selected for initial evaluation. The automated system for the dishwasher line would replace an existing system (purchased one year ago for $6 million). Although the existing system will be fully depreciated in nine years, it is expected to last another 10 years. The automated system would also have a useful life of 10 years.

The automated system will cost $34 million to purchase, plus an estimated $20 million in software and implementation. (Assume that all investment outlays occur at the beginning of the first year.) If the automated equipment is purchased, the old equipment can be sold for $3 million.

The automated system will require fewer parts for production and will produce with less waste. Because of this, the direct material cost per unit will be reduced by 25 percent. Automation will also require fewer support activities, and as a consequence, volume-related overhead will be reduced by $4 per unit and direct fixed overhead (other than depreciation) by $17 per unit. Direct labor is reduced by 60 percent. Assume, for simplicity, that the new investment will be depreciated on a pure straight-line basis for tax purposes with no salvage value. Ignore the half-life convention.

The firm's cost of capital is 12 percent, but management chooses to use 20 percent as the required rate of return for evaluation of investments. The combined federal and state tax rate is 40 percent.

Required:

1. Compute the net present value for the old system and the automated system. Which system would the company choose?

2. Repeat the net present value analysis of Requirement 1, using 12 percent as the discount rate.

3. Upon seeing the projected sales for the old system, the marketing manager commented: "Sales of 100,000 units per year cannot be maintained in the current competitive environment for more than one year unless we buy the automated system. The automated system will allow us to compete on the basis of quality and lead time. If we keep the old system, our sales will drop by 10,000 units per year." Repeat the net present value analysis, using this new information and a 12 percent discount rate.

4. An industrial engineer for Mallette noticed that salvage value for the automated equipment had not been included in the analysis. He estimated that the equipment could be sold for $4 million at the end of 10 years. He also estimated that the equipment of the old system would have no salvage value at the end of 10 years. Repeat the net present value analysis using this information, the information in Requirement 3, and a 12 percent discount rate.

5. Given the outcomes of the previous four requirements, comment on the importance of providing accurate inputs for assessing investments in automated manufacturing systems.

Unlock Deck

Unlock for access to all 47 flashcards in this deck.

Unlock Deck

k this deck

13

Payback and ARR

Each of the following scenarios is independent. All cash flows are after-tax cash flows.

Required:

1. Brad Blaylock has purchased a tractor for $93,750. He expects to receive a net cash flow of $31,250 per year from the investment. What is the payback period for Jim?

2. Bertha Lafferty invested $360,000 in a laundromat. The facility has a 10-year life expectancy with no expected salvage value. The laundromat will produce a net cash flow of $108,000 per year. What is the accounting rate of return?

3. Melannie Bayless has purchased a business building for $336,000. She expects to receive the following cash flows over a 10-year period:

Year 1: $42,000

Year 2: $58,800

Years 3-10: $84,000

What is the payback period for Melannie? What is the accounting rate of return?

Each of the following scenarios is independent. All cash flows are after-tax cash flows.

Required:

1. Brad Blaylock has purchased a tractor for $93,750. He expects to receive a net cash flow of $31,250 per year from the investment. What is the payback period for Jim?

2. Bertha Lafferty invested $360,000 in a laundromat. The facility has a 10-year life expectancy with no expected salvage value. The laundromat will produce a net cash flow of $108,000 per year. What is the accounting rate of return?

3. Melannie Bayless has purchased a business building for $336,000. She expects to receive the following cash flows over a 10-year period:

Year 1: $42,000

Year 2: $58,800

Years 3-10: $84,000

What is the payback period for Melannie? What is the accounting rate of return?

Unlock Deck

Unlock for access to all 47 flashcards in this deck.

Unlock Deck

k this deck

14

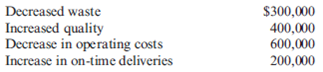

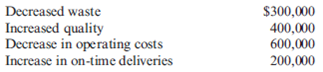

Advanced Technology, Payback, NPV, IRR, Sensitivity Analysis

Gina Ripley, president of Dearing Company, is considering the purchase of a computer-aided manufacturing system. The annual net cash benefits and savings associated with the system are described as follows:

The system will cost $9,000,000 and last 10 years. The company's cost of capital is 12 percent.

Required:

1. Calculate the payback period for the system. Assume that the company has a policy of only accepting projects with a payback of five years or less. Would the system be acquired?

2. Calculate the NPV and IRR for the project. Should the system be purchased-even if it does not meet the payback criterion?

3. The project manager reviewed the projected cash flows and pointed out that two items had been missed. First, the system would have a salvage value, net of any tax effects, of $1,000,000 at the end of 10 years. Second, the increased quality and delivery performance would allow the company to increase its market share by 20 percent. This would produce an additional annual net benefit of $300,000. Recalculate the payback period, NPV, and IRR given this new information. (For the IRR computation, initially ignore salvage value.) Does the decision change? Suppose that the salvage value is only half what is projected. Does this make a difference in the outcome? Does salvage value have any real bearing on the company's decision?

Gina Ripley, president of Dearing Company, is considering the purchase of a computer-aided manufacturing system. The annual net cash benefits and savings associated with the system are described as follows:

The system will cost $9,000,000 and last 10 years. The company's cost of capital is 12 percent.

Required:

1. Calculate the payback period for the system. Assume that the company has a policy of only accepting projects with a payback of five years or less. Would the system be acquired?

2. Calculate the NPV and IRR for the project. Should the system be purchased-even if it does not meet the payback criterion?

3. The project manager reviewed the projected cash flows and pointed out that two items had been missed. First, the system would have a salvage value, net of any tax effects, of $1,000,000 at the end of 10 years. Second, the increased quality and delivery performance would allow the company to increase its market share by 20 percent. This would produce an additional annual net benefit of $300,000. Recalculate the payback period, NPV, and IRR given this new information. (For the IRR computation, initially ignore salvage value.) Does the decision change? Suppose that the salvage value is only half what is projected. Does this make a difference in the outcome? Does salvage value have any real bearing on the company's decision?

Unlock Deck

Unlock for access to all 47 flashcards in this deck.

Unlock Deck

k this deck

15

NPV, Make or Buy, MACRS, Basic Analysis

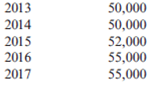

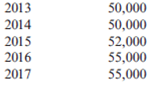

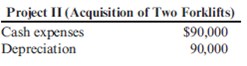

Jonfran Company manufactures three different models of paper shredders including the waste container, which serves as the base. While the shredder heads are different for all three models, the waste container is the same. The number of waste containers that Jonfran will need during the following years is estimated as follows:

The equipment used to manufacture the waste container must be replaced because it is broken and cannot be repaired. The new equipment would have a purchase price of $945,000 with terms of 2/10, n/30; the company's policy is to take all purchase discounts. The freight on the equipment would be $11,000, and installation costs would total $22,900. The equipment would be purchased in December 2012 and placed into service on January 1, 2013. It would have a fiveyear economic life and would be treated as three-year property under MACRS. This equipment is expected to have a salvage value of $12,000 at the end of its economic life in 2017. The new equipment would be more efficient than the old equipment, resulting in a 25 percent reduction in both direct materials and variable overhead. The savings in direct materials would result in an additional one-time decrease in working capital requirements of $2,500, resulting from a reduction in direct material inventories. This working capital reduction would be recognized at the time of equipment acquisition.

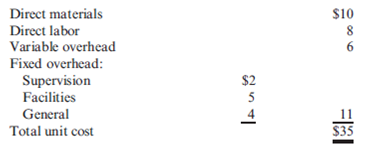

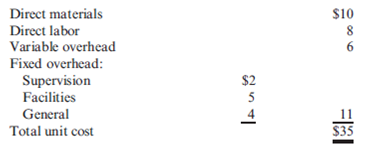

The old equipment is fully depreciated and is not included in the fixed overhead. The old equipment from the plant can be sold for a salvage amount of $1,500. Rather than replace the equipment, one of Jonfran's production managers has suggested that the waste containers be purchased. One supplier has quoted a price of $27 per container. This price is $8 less than Jonfran's current manufacturing cost, which is as follows:

Jonfran uses a plantwide fixed overhead rate in its operations. If the waste containers are purchased outside, the salary and benefits of one supervisor, included in fixed overhead at $45,000, would be eliminated. There would be no other changes in the other cash and noncash items included in fixed overhead except depreciation on the new equipment.

Jonfran is subject to a 40 percent tax rate. Management assumes that all cash flows occur at the end of the year and uses a 12 percent after-tax discount rate.

Required:

1. Prepare a schedule of cash flows for the make alternative. Calculate the NPV of the make alternative.

2. Prepare a schedule of cash flows for the buy alternative. Calculate the NPV of the buy alternative.

3. Which should Jonfran do-make or buy the containers? What qualitative factors should be considered? ( CMA adapted )

Jonfran Company manufactures three different models of paper shredders including the waste container, which serves as the base. While the shredder heads are different for all three models, the waste container is the same. The number of waste containers that Jonfran will need during the following years is estimated as follows:

The equipment used to manufacture the waste container must be replaced because it is broken and cannot be repaired. The new equipment would have a purchase price of $945,000 with terms of 2/10, n/30; the company's policy is to take all purchase discounts. The freight on the equipment would be $11,000, and installation costs would total $22,900. The equipment would be purchased in December 2012 and placed into service on January 1, 2013. It would have a fiveyear economic life and would be treated as three-year property under MACRS. This equipment is expected to have a salvage value of $12,000 at the end of its economic life in 2017. The new equipment would be more efficient than the old equipment, resulting in a 25 percent reduction in both direct materials and variable overhead. The savings in direct materials would result in an additional one-time decrease in working capital requirements of $2,500, resulting from a reduction in direct material inventories. This working capital reduction would be recognized at the time of equipment acquisition.

The old equipment is fully depreciated and is not included in the fixed overhead. The old equipment from the plant can be sold for a salvage amount of $1,500. Rather than replace the equipment, one of Jonfran's production managers has suggested that the waste containers be purchased. One supplier has quoted a price of $27 per container. This price is $8 less than Jonfran's current manufacturing cost, which is as follows:

Jonfran uses a plantwide fixed overhead rate in its operations. If the waste containers are purchased outside, the salary and benefits of one supervisor, included in fixed overhead at $45,000, would be eliminated. There would be no other changes in the other cash and noncash items included in fixed overhead except depreciation on the new equipment.

Jonfran is subject to a 40 percent tax rate. Management assumes that all cash flows occur at the end of the year and uses a 12 percent after-tax discount rate.

Required:

1. Prepare a schedule of cash flows for the make alternative. Calculate the NPV of the make alternative.

2. Prepare a schedule of cash flows for the buy alternative. Calculate the NPV of the buy alternative.

3. Which should Jonfran do-make or buy the containers? What qualitative factors should be considered? ( CMA adapted )

Unlock Deck

Unlock for access to all 47 flashcards in this deck.

Unlock Deck

k this deck

16

Explain how the NPV is used to determine whether a project should be accepted or rejected.

Unlock Deck

Unlock for access to all 47 flashcards in this deck.

Unlock Deck

k this deck

17

NPV Versus IRR

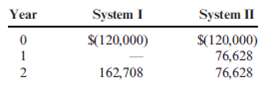

Covington Pharmacies has decided to automate its insurance claims process. Two networked computer systems are being considered. The systems have an expected life of two years. The net cash flows associated with the systems are as follows. The cash benefits represent the savings created by switching from a manual to an automated system.

The company's cost of capital is 10 percent.

Required:

1. Compute the NPV and the IRR for each investment.

2. Show that the project with the larger NPV is the correct choice for the company.

Covington Pharmacies has decided to automate its insurance claims process. Two networked computer systems are being considered. The systems have an expected life of two years. The net cash flows associated with the systems are as follows. The cash benefits represent the savings created by switching from a manual to an automated system.

The company's cost of capital is 10 percent.

Required:

1. Compute the NPV and the IRR for each investment.

2. Show that the project with the larger NPV is the correct choice for the company.

Unlock Deck

Unlock for access to all 47 flashcards in this deck.

Unlock Deck

k this deck

18

Structured Problem Solving, Cash Flows, NPV, Choice of Discount Rate, Advanced Manufacturing Environment

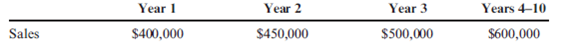

Brindon Thayn, president and owner of Orangeville Metal Works, has just returned from a trip to Europe. While there, he toured several plants that use robotic manufacturing. Seeing the efficiency and success of these companies, Brindon became convinced that robotic manufacturing is essential for Orangeville to maintain its competitive position.

Based on this conviction, Brindon requested an analysis detailing the costs and benefits of robotic manufacturing for the materials handling and merchandising equipment group. This group of products consists of such items as cooler shelving, stocking carts, and bakery racks. The products are sold directly to supermarkets.

A committee, consisting of the controller, the marketing manager, and the production manager, was given the responsibility to prepare the analysis. As a starting point, the controller provided the following information on expected revenues and expenses for the existing manual system:

Given the current competitive environment, the marketing manager thought that the preceding level of profitability would not likely change for the next decade.

After some investigation into various robotic equipment, the committee settled on an Aide 900 system, a robot that has the capability to weld stainless steel or aluminum. It is capable of being programmed to adjust the path, angle, and speed of the torch. The production manager was excited about the robotic system because it would eliminate the need to hire welders. This was an attractive possibility because the market for welders seemed perpetually tight. By reducing the dependence on welders, better production scheduling and fewer late deliveries would result. Moreover, the robot's production rate is four times that of a person.

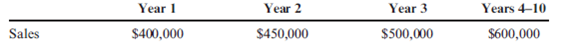

It was also discovered that robotic welding is superior in quality to manual welding. As a consequence, some of the costs of poor quality could be reduced. By providing better-quality products and avoiding late deliveries, the marketing manager was convinced that the company would have such a competitive edge that it would increase sales by 50 percent for the affected product group by the end of the fourth year. The marketing manager provided the following projections for the next 10 years, the useful life of the robotic equipment:

Currently, the company employs four welders, who work 40 hours per week and 50 weeks per year at an average wage of $10 per hour. If the robot is acquired, it will need one operator, who will be paid $10 per hour. Because of improved quality, the robotic system will also reduce the cost of direct materials by 25 percent, the cost of variable overhead by 33.33 percent, and variable selling expenses by 10 percent. All of these reductions will take place immediately after the robotic system is in place and operating. Fixed costs will be increased by the depreciation associated with the robot. The robot will be depreciated using MACRS. (The manual system uses straight-line depreciation without a half-year convention and has a current book value of $200,000.) If the robotic system is acquired, the old system will be sold for $40,000.

The robotic system requires the following initial investment:

At the end of 10 years, the robot will have a salvage value of $20,000. Assume that the company's cost of capital is 12 percent. The tax rate is 40 percent.

Required:

1. Prepare a schedule of after-tax cash flows for the manual and robotic systems.

2. Using the schedule of cash flows computed in Requirement 1, compute the NPV for each system. Should the company invest in the robotic system?

3. In practice, many financial officers tend to use a higher discount rate than is justified by the firm's cost of capital. For example, a firm may use a discount rate of 20 percent when its cost of capital is or could be 12 percent. Offer some reasons for this practice. Assume that the annual after-tax cash benefit of adopting the robotic system is $80,000 per year more than the manual system. The initial outlay for the robotic system is $340,000. Compute the NPV using 12 percent and 20 percent. Would the robotic system be acquired if 20 percent is used? Could this conservative approach have a negative impact on a firm's ability to stay competitive?

Brindon Thayn, president and owner of Orangeville Metal Works, has just returned from a trip to Europe. While there, he toured several plants that use robotic manufacturing. Seeing the efficiency and success of these companies, Brindon became convinced that robotic manufacturing is essential for Orangeville to maintain its competitive position.

Based on this conviction, Brindon requested an analysis detailing the costs and benefits of robotic manufacturing for the materials handling and merchandising equipment group. This group of products consists of such items as cooler shelving, stocking carts, and bakery racks. The products are sold directly to supermarkets.

A committee, consisting of the controller, the marketing manager, and the production manager, was given the responsibility to prepare the analysis. As a starting point, the controller provided the following information on expected revenues and expenses for the existing manual system:

Given the current competitive environment, the marketing manager thought that the preceding level of profitability would not likely change for the next decade.

After some investigation into various robotic equipment, the committee settled on an Aide 900 system, a robot that has the capability to weld stainless steel or aluminum. It is capable of being programmed to adjust the path, angle, and speed of the torch. The production manager was excited about the robotic system because it would eliminate the need to hire welders. This was an attractive possibility because the market for welders seemed perpetually tight. By reducing the dependence on welders, better production scheduling and fewer late deliveries would result. Moreover, the robot's production rate is four times that of a person.

It was also discovered that robotic welding is superior in quality to manual welding. As a consequence, some of the costs of poor quality could be reduced. By providing better-quality products and avoiding late deliveries, the marketing manager was convinced that the company would have such a competitive edge that it would increase sales by 50 percent for the affected product group by the end of the fourth year. The marketing manager provided the following projections for the next 10 years, the useful life of the robotic equipment:

Currently, the company employs four welders, who work 40 hours per week and 50 weeks per year at an average wage of $10 per hour. If the robot is acquired, it will need one operator, who will be paid $10 per hour. Because of improved quality, the robotic system will also reduce the cost of direct materials by 25 percent, the cost of variable overhead by 33.33 percent, and variable selling expenses by 10 percent. All of these reductions will take place immediately after the robotic system is in place and operating. Fixed costs will be increased by the depreciation associated with the robot. The robot will be depreciated using MACRS. (The manual system uses straight-line depreciation without a half-year convention and has a current book value of $200,000.) If the robotic system is acquired, the old system will be sold for $40,000.

The robotic system requires the following initial investment:

At the end of 10 years, the robot will have a salvage value of $20,000. Assume that the company's cost of capital is 12 percent. The tax rate is 40 percent.

Required:

1. Prepare a schedule of after-tax cash flows for the manual and robotic systems.

2. Using the schedule of cash flows computed in Requirement 1, compute the NPV for each system. Should the company invest in the robotic system?

3. In practice, many financial officers tend to use a higher discount rate than is justified by the firm's cost of capital. For example, a firm may use a discount rate of 20 percent when its cost of capital is or could be 12 percent. Offer some reasons for this practice. Assume that the annual after-tax cash benefit of adopting the robotic system is $80,000 per year more than the manual system. The initial outlay for the robotic system is $340,000. Compute the NPV using 12 percent and 20 percent. Would the robotic system be acquired if 20 percent is used? Could this conservative approach have a negative impact on a firm's ability to stay competitive?

Unlock Deck

Unlock for access to all 47 flashcards in this deck.

Unlock Deck

k this deck

19

(Appendix A) Future Value, Present Value

The following cases are each independent of the others.

Required:

1. Sam Lilliam places $5,000 in a savings account that pays 3 percent. Suppose Sam leaves the original deposit plus any interest in the account for two years. How much will Sam have in savings after two years?

2. Suppose that the parents of a 12-year-old son want to have $80,000 in a fund six years from now to provide support for his college education. How much must they invest now to have the desired amount if the investment can earn 4 percent? 6 percent? 8 percent?

3. Killian Manufacturing is asking $500,000 for automated equipment, which is expected to last six years and will generate equal annual net cash inflows (because of reductions in labor costs, material waste, and so on). What is the minimum cash inflow that must be realized each year to justify the acquisition? The cost of capital is 8 percent.

The following cases are each independent of the others.

Required:

1. Sam Lilliam places $5,000 in a savings account that pays 3 percent. Suppose Sam leaves the original deposit plus any interest in the account for two years. How much will Sam have in savings after two years?

2. Suppose that the parents of a 12-year-old son want to have $80,000 in a fund six years from now to provide support for his college education. How much must they invest now to have the desired amount if the investment can earn 4 percent? 6 percent? 8 percent?

3. Killian Manufacturing is asking $500,000 for automated equipment, which is expected to last six years and will generate equal annual net cash inflows (because of reductions in labor costs, material waste, and so on). What is the minimum cash inflow that must be realized each year to justify the acquisition? The cost of capital is 8 percent.

Unlock Deck

Unlock for access to all 47 flashcards in this deck.

Unlock Deck

k this deck

20

Computation of After-Tax Cash Flows

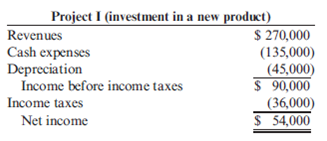

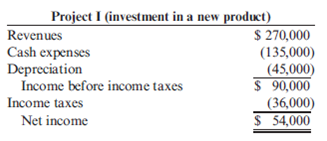

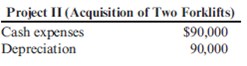

Postman Company is considering two independent projects. One project involves a new product line, and the other involves the acquisition of forklifts for the Materials Handling Department. The projected annual operating revenues and expenses are as follows:

Required:

Compute the after-tax cash flows of each project. The tax rate is 40 percent and includes federal and state assessments.

Postman Company is considering two independent projects. One project involves a new product line, and the other involves the acquisition of forklifts for the Materials Handling Department. The projected annual operating revenues and expenses are as follows:

Required:

Compute the after-tax cash flows of each project. The tax rate is 40 percent and includes federal and state assessments.

Unlock Deck

Unlock for access to all 47 flashcards in this deck.

Unlock Deck

k this deck

21

Payback Period

Jan Booth is considering investing in either a storage facility or a car wash facility. Both projects have a five-year life and require an investment of $360,000. The cash flow patterns for each project are given below.

Storage facility: Even cash flows of $120,000 per year

Car wash: $112,500, $142,500, $60,000, $120,000, and $90,000

Required:

1. Calculate the payback period for the storage facility (even cash flows).

2. Calculate the payback period for the car wash facility (uneven cash flows). Which project should be accepted based on payback analysis? Explain.

3. What if a third mutually exclusive project, a laundry facility, became available with the same investment and annual cash flows of $150,000? Now which project would be chosen?

Jan Booth is considering investing in either a storage facility or a car wash facility. Both projects have a five-year life and require an investment of $360,000. The cash flow patterns for each project are given below.

Storage facility: Even cash flows of $120,000 per year

Car wash: $112,500, $142,500, $60,000, $120,000, and $90,000

Required:

1. Calculate the payback period for the storage facility (even cash flows).

2. Calculate the payback period for the car wash facility (uneven cash flows). Which project should be accepted based on payback analysis? Explain.

3. What if a third mutually exclusive project, a laundry facility, became available with the same investment and annual cash flows of $150,000? Now which project would be chosen?

Unlock Deck

Unlock for access to all 47 flashcards in this deck.

Unlock Deck

k this deck

22

Explain why NPV is generally preferred over IRR when choosing among competing or mutually exclusive projects. Why would managers continue to use IRR to choose among mutually exclusive projects?

Unlock Deck

Unlock for access to all 47 flashcards in this deck.

Unlock Deck

k this deck

23

MACRS, NPV

Lilly Company is planning to buy a set of special tools for its grinding operation. The cost of the tools is $18,000. The tools have a three-year life and qualify for the use of the three-year MACRS. The tax rate is 40 percent; the cost of capital is 12 percent.

Required:

1. Calculate the present value of the tax depreciation shield, assuming that straight-line depreciation with a half-year life is used.

2. Calculate the present value of the tax depreciation shield, assuming that MACRS is used.

3. What is the benefit to the company of using MACRS?

Lilly Company is planning to buy a set of special tools for its grinding operation. The cost of the tools is $18,000. The tools have a three-year life and qualify for the use of the three-year MACRS. The tax rate is 40 percent; the cost of capital is 12 percent.

Required:

1. Calculate the present value of the tax depreciation shield, assuming that straight-line depreciation with a half-year life is used.

2. Calculate the present value of the tax depreciation shield, assuming that MACRS is used.

3. What is the benefit to the company of using MACRS?

Unlock Deck

Unlock for access to all 47 flashcards in this deck.

Unlock Deck

k this deck

24

Explain the difference between independent projects and mutually exclusive projects.

Unlock Deck

Unlock for access to all 47 flashcards in this deck.

Unlock Deck

k this deck

25

NPV and IRR

Each of the following scenarios is independent. All cash flows are after-tax cash flows.

Required:

1. Patz Corporation is considering the purchase of a computer-aided manufacturing system. The cash benefits will be $800,000 per year. The system costs $4,000,000 and will last eight years. Compute the NPV assuming a discount rate of 10 percent. Should the company buy the new system?

2. Sterling Wetzel has just invested $270,000 in a restaurant specializing in German food. He expects to receive $43,470 per year for the next eight years. His cost of capital is 5.5 percent. Compute the internal rate of return. Did Sterling make a good decision?

Each of the following scenarios is independent. All cash flows are after-tax cash flows.

Required:

1. Patz Corporation is considering the purchase of a computer-aided manufacturing system. The cash benefits will be $800,000 per year. The system costs $4,000,000 and will last eight years. Compute the NPV assuming a discount rate of 10 percent. Should the company buy the new system?

2. Sterling Wetzel has just invested $270,000 in a restaurant specializing in German food. He expects to receive $43,470 per year for the next eight years. His cost of capital is 5.5 percent. Compute the internal rate of return. Did Sterling make a good decision?

Unlock Deck

Unlock for access to all 47 flashcards in this deck.

Unlock Deck

k this deck

26

(2011 CPA Exam, adapted) A corporation is considering purchasing a machine that costs $100,000 and has a $20,000 salvage value. The machine will provide net annual cash inflows of $25,000 per year and has a sixyear life. The corporation uses a discount rate of 10%. The discount factor for the present value of a single sum six years in the future is 0.564. The discount factor for the present value of an annuity for six years is 4.355. What is the net present value of the machine?

A) ($2,405)

B) $8,875

C) $20,155

D) $28,875

A) ($2,405)

B) $8,875

C) $20,155

D) $28,875

Unlock Deck

Unlock for access to all 47 flashcards in this deck.

Unlock Deck

k this deck

27

Accounting Rate of Return

WeCare Clinic is planning on investing in some new echocardiogram equipment that will require an initial outlay of $170,000. The system has an expected life of five years and no expected salvage value. The investment is expected to produce the following net cash flows over its life: $68,000, $68,000, $85,000, $85,000, and $102,000.

Required:

1. Calculate the annual net income for each of the five years.

2. Calculate the accounting rate of return.

3. What if a second competing revenue-producing investment has the same initial outlay and salvage value but the following cash flows (in chronological sequence): $102,000, $102,000, $102,000, $68,000, and $17,000? Using the accounting rate of return metric, which project should be selected: the first or the second? Which project is really the better of the two?

WeCare Clinic is planning on investing in some new echocardiogram equipment that will require an initial outlay of $170,000. The system has an expected life of five years and no expected salvage value. The investment is expected to produce the following net cash flows over its life: $68,000, $68,000, $85,000, $85,000, and $102,000.

Required:

1. Calculate the annual net income for each of the five years.

2. Calculate the accounting rate of return.

3. What if a second competing revenue-producing investment has the same initial outlay and salvage value but the following cash flows (in chronological sequence): $102,000, $102,000, $102,000, $68,000, and $17,000? Using the accounting rate of return metric, which project should be selected: the first or the second? Which project is really the better of the two?

Unlock Deck

Unlock for access to all 47 flashcards in this deck.

Unlock Deck

k this deck

28

Why is it important to have accurate projections of cash flows for potential capital investments?

Unlock Deck

Unlock for access to all 47 flashcards in this deck.

Unlock Deck

k this deck

29

(2011 CPA Exam, adapted) Which of the following metrics equates the present value of a project's expected cash inflows to the present value of the project's expected costs?

A) Internal rate of return

B) Net present value

C) Return on assets

D) Economic value-added

A) Internal rate of return

B) Net present value

C) Return on assets

D) Economic value-added

Unlock Deck

Unlock for access to all 47 flashcards in this deck.

Unlock Deck

k this deck

30

Explain why the timing and quantity of cash flows are important in capital investment decisions.

Unlock Deck

Unlock for access to all 47 flashcards in this deck.

Unlock Deck

k this deck

31

Basic Concepts

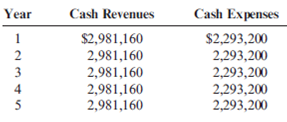

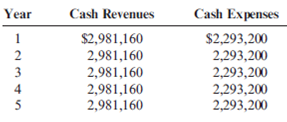

Roberts Company is considering an investment in equipment that is capable of producing more efficiently than the current technology. The outlay required is $2,293,200. The equipment is expected to last five years and will have no salvage value. The expected cash flows associated with the project are as follows:

Required:

1. Compute the project's payback period.

2. Compute the project's accounting rate of return.

3. Compute the project's net present value, assuming a required rate of return of 10 percent.

4. Compute the project's internal rate of return.

Roberts Company is considering an investment in equipment that is capable of producing more efficiently than the current technology. The outlay required is $2,293,200. The equipment is expected to last five years and will have no salvage value. The expected cash flows associated with the project are as follows:

Required:

1. Compute the project's payback period.

2. Compute the project's accounting rate of return.

3. Compute the project's net present value, assuming a required rate of return of 10 percent.

4. Compute the project's internal rate of return.

Unlock Deck

Unlock for access to all 47 flashcards in this deck.

Unlock Deck

k this deck

32

(2009 CPA Exam, adapted) Which of the following rates is most commonly compared to the internal rate of return to evaluate whether to make an investment?

A) Short-term rate on U.S. Treasury bonds

B) Prime rate of interest

C) Weighted average cost of capital

D) Long-term rate on U.S. Treasury bonds

A) Short-term rate on U.S. Treasury bonds

B) Prime rate of interest

C) Weighted average cost of capital

D) Long-term rate on U.S. Treasury bonds

Unlock Deck

Unlock for access to all 47 flashcards in this deck.

Unlock Deck

k this deck

33

Net Present Value

Carsen Sorensen, controller of Thayn Company, just received the following data associated with production of a new product:

• Expected annual revenues: $750,000

• Projected product life cycle: five years

• Equipment: $800,000 with a salvage value of $100,000 after five years

• Expected increase in working capital: $100,000 (recoverable at the end of five years)

• Annual cash operating expenses: estimated at $450,000

• Required rate of return: 8 percent

Required:

1. Estimate the annual cash flows for the new product.

2. Using the estimated annual cash flows, calculate the NPV.

3. What if revenues were overestimated by $150,000? Redo the NPV analysis, correcting for this error. Assume the operating expenses remain the same.

Carsen Sorensen, controller of Thayn Company, just received the following data associated with production of a new product:

• Expected annual revenues: $750,000

• Projected product life cycle: five years

• Equipment: $800,000 with a salvage value of $100,000 after five years

• Expected increase in working capital: $100,000 (recoverable at the end of five years)

• Annual cash operating expenses: estimated at $450,000

• Required rate of return: 8 percent

Required:

1. Estimate the annual cash flows for the new product.

2. Using the estimated annual cash flows, calculate the NPV.

3. What if revenues were overestimated by $150,000? Redo the NPV analysis, correcting for this error. Assume the operating expenses remain the same.

Unlock Deck

Unlock for access to all 47 flashcards in this deck.

Unlock Deck

k this deck

34

What are the principal tax implications that should be considered in Year 0?

Unlock Deck

Unlock for access to all 47 flashcards in this deck.

Unlock Deck

k this deck

35

(2010 CPA Exam, adapted) Salem Co. is considering a project that yields annual net cash inflows of $420,000 for years 1 through 5, and a net cash inflow of $100,000 in year 6. The project will require an initial investment of $1,800,000. Salem's cost of capital is 10 percent. Present value information is presented below:

Present value of $1 for five years at 10 percent is 0.62.

Present value of $1 for six years at 10 percent is 0.56.

Present value of an annuity of $1 for five years at 10 percent is 3.79.

What was Salem's expected net present value for this project?

A) $83,000

B) ($108,200)

C) ($152,200)

D) ($442,000)

Present value of $1 for five years at 10 percent is 0.62.

Present value of $1 for six years at 10 percent is 0.56.

Present value of an annuity of $1 for five years at 10 percent is 3.79.

What was Salem's expected net present value for this project?

A) $83,000

B) ($108,200)

C) ($152,200)

D) ($442,000)

Unlock Deck

Unlock for access to all 47 flashcards in this deck.

Unlock Deck

k this deck

36

The time value of money is ignored by the payback period and the accounting rate of return. Explain why this is a major deficiency in these two models.

Unlock Deck

Unlock for access to all 47 flashcards in this deck.

Unlock Deck

k this deck

37

NPV

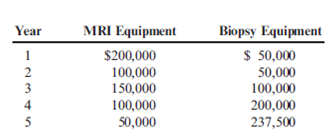

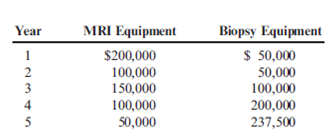

A clinic is considering the possibility of two new purchases: new MRI equipment and new biopsy equipment. Each project requires an investment of $425,000. The expected life for each is five years with no expected salvage value. The net cash inflows associated with the two independent projects are as follows:

Required:

Compute the net present value of each project, assuming a required rate of 12 percent.

A clinic is considering the possibility of two new purchases: new MRI equipment and new biopsy equipment. Each project requires an investment of $425,000. The expected life for each is five years with no expected salvage value. The net cash inflows associated with the two independent projects are as follows:

Required:

Compute the net present value of each project, assuming a required rate of 12 percent.

Unlock Deck

Unlock for access to all 47 flashcards in this deck.

Unlock Deck

k this deck

38

(2010 CPA Exam, adapted) Which of the following statements is correct regarding the payback method as a capital budgeting technique?

A) The payback method considers the time value of money.

B) An advantage of the payback method is that it indicates if an investment will be profitable.

C) The payback method provides the years needed to recoup the investment in a project.

D) Payback is calculated by dividing the annual cash inflows by the net investment.

A) The payback method considers the time value of money.

B) An advantage of the payback method is that it indicates if an investment will be profitable.

C) The payback method provides the years needed to recoup the investment in a project.

D) Payback is calculated by dividing the annual cash inflows by the net investment.

Unlock Deck

Unlock for access to all 47 flashcards in this deck.

Unlock Deck

k this deck

39

Internal Rate of Return

Manzer Enterprises is considering two independent investments:

A new automated materials handling system that costs $900,000 and will produce net cash inflows of $300,000 at the end of each year for the next four years.

A computer-aided manufacturing system that costs $775,000 and will produce labor savings of $400,000 and $500,000 at the end of the first year and second year, respectively.

Manzer has a cost of capital of 8 percent.

Required:

1. Calculate the IRR for the first investment and determine if it is acceptable or not.

2. Calculate the IRR of the second investment and comment on its acceptability. Use 12 percent as the first guess.

3. What if the cash flows for the first investment are $250,000 instead of $300,000?

Manzer Enterprises is considering two independent investments:

A new automated materials handling system that costs $900,000 and will produce net cash inflows of $300,000 at the end of each year for the next four years.

A computer-aided manufacturing system that costs $775,000 and will produce labor savings of $400,000 and $500,000 at the end of the first year and second year, respectively.

Manzer has a cost of capital of 8 percent.

Required:

1. Calculate the IRR for the first investment and determine if it is acceptable or not.

2. Calculate the IRR of the second investment and comment on its acceptability. Use 12 percent as the first guess.

3. What if the cash flows for the first investment are $250,000 instead of $300,000?

Unlock Deck

Unlock for access to all 47 flashcards in this deck.

Unlock Deck

k this deck

40

Explain why the MACRS method of recognizing depreciation is better than the straight-line method.

Unlock Deck

Unlock for access to all 47 flashcards in this deck.

Unlock Deck

k this deck

41

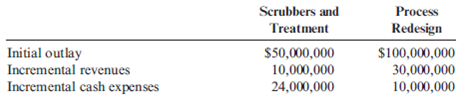

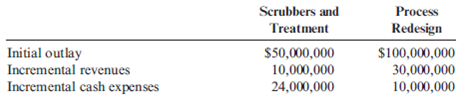

Pollution Prevention, P2 Investment

Heaps Company produces jewelry that requires electroplating with gold, silver, and other valuable metals. Electroplating uses large amounts of water and chemicals, producing wastewater with a number of toxic residuals. Currently, Heaps uses settlement tanks to remove waste; unfortunately, the approach is inefficient, and much of the toxic residue is left in the water that is discharged into a local river. The amount of toxic discharge exceeds the legal, allowable amounts, and the company is faced with substantial, ongoing environmental fines. The environmental violations are also drawing unfavorable public reaction, and sales are being affected. A lawsuit is also impending, which could prove to be quite costly.

Management is now considering the installation of a zero-discharge, closed-loop system to treat the wastewater. The proposed closed-loop system would not only purify the wastewater, but also produce cleaner water than that currently being used, increasing plating quality. The closed-loop system would produce only four pounds of sludge, and the sludge would be virtually pure metal, with significant market value. The system requires an investment of $630,000 and will cost $45,000 in increased annual operation plus an annual purchase of $7,500 of filtration medium. However, management projects the following savings:

The equipment qualifies as a seven-year MACRS asset. Management has decided to use straight-line depreciation for tax purposes, using the required half-year convention. The tax rate is 40 percent. The projected life of the system is 10 years. The hurdle rate is 16 percent for all capital budgeting projects, although the company's cost of capital is 12 percent.

Required:

1. Based on the financial data provided, prepare a schedule of expected cash flows.

2. What is the payback period?

3. Calculate the NPV of the closed-loop system. Should the company invest in the system?

4. The calculation in Requirement 3 ignored several factors that could affect the project's viability: savings from avoiding the annual fines, positive effect on sales due to favorable environmental publicity, increased plating quality from the new system, and the avoidance of the lawsuit. Can these factors be quantified? If so, should they have been included in the analysis? Suppose, for example, that the annual fines being incurred are $75,000, the sales effect is $60,000 per year, the quality effect is not estimable, and cancellation of the lawsuit because of the new system would avoid an expected settlement at the end of Year 3 (including legal fees) of $300,000. Assuming these are all after-tax amounts, what effect would their inclusion have on the payback period? On the NPV?

Heaps Company produces jewelry that requires electroplating with gold, silver, and other valuable metals. Electroplating uses large amounts of water and chemicals, producing wastewater with a number of toxic residuals. Currently, Heaps uses settlement tanks to remove waste; unfortunately, the approach is inefficient, and much of the toxic residue is left in the water that is discharged into a local river. The amount of toxic discharge exceeds the legal, allowable amounts, and the company is faced with substantial, ongoing environmental fines. The environmental violations are also drawing unfavorable public reaction, and sales are being affected. A lawsuit is also impending, which could prove to be quite costly.

Management is now considering the installation of a zero-discharge, closed-loop system to treat the wastewater. The proposed closed-loop system would not only purify the wastewater, but also produce cleaner water than that currently being used, increasing plating quality. The closed-loop system would produce only four pounds of sludge, and the sludge would be virtually pure metal, with significant market value. The system requires an investment of $630,000 and will cost $45,000 in increased annual operation plus an annual purchase of $7,500 of filtration medium. However, management projects the following savings:

The equipment qualifies as a seven-year MACRS asset. Management has decided to use straight-line depreciation for tax purposes, using the required half-year convention. The tax rate is 40 percent. The projected life of the system is 10 years. The hurdle rate is 16 percent for all capital budgeting projects, although the company's cost of capital is 12 percent.

Required:

1. Based on the financial data provided, prepare a schedule of expected cash flows.

2. What is the payback period?

3. Calculate the NPV of the closed-loop system. Should the company invest in the system?

4. The calculation in Requirement 3 ignored several factors that could affect the project's viability: savings from avoiding the annual fines, positive effect on sales due to favorable environmental publicity, increased plating quality from the new system, and the avoidance of the lawsuit. Can these factors be quantified? If so, should they have been included in the analysis? Suppose, for example, that the annual fines being incurred are $75,000, the sales effect is $60,000 per year, the quality effect is not estimable, and cancellation of the lawsuit because of the new system would avoid an expected settlement at the end of Year 3 (including legal fees) of $300,000. Assuming these are all after-tax amounts, what effect would their inclusion have on the payback period? On the NPV?

Unlock Deck

Unlock for access to all 47 flashcards in this deck.

Unlock Deck

k this deck

42

What is the payback period? Name and discuss three possible reasons that the payback period is used to help make capital investment decisions.

Unlock Deck

Unlock for access to all 47 flashcards in this deck.

Unlock Deck

k this deck

43

Payback, Accounting Rate of Return

Refer to Exercise 19.11.

1. Compute the payback period for each project. Assume that the manager of the clinic accepts only projects with a payback period of three years or less. Offer some reasons why this may be a rational strategy even though the NPV computed in Exercise 19.11 may indicate otherwise.

2. Compute the accounting rate of return for each project.

Refer to Exercise 19.11.

1. Compute the payback period for each project. Assume that the manager of the clinic accepts only projects with a payback period of three years or less. Offer some reasons why this may be a rational strategy even though the NPV computed in Exercise 19.11 may indicate otherwise.

2. Compute the accounting rate of return for each project.

Unlock Deck

Unlock for access to all 47 flashcards in this deck.

Unlock Deck

k this deck

44

Discount Rates, Quality, Market Share, Contemporary Manufacturing Environment

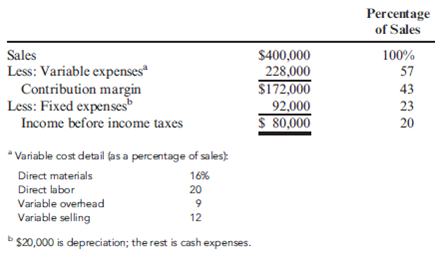

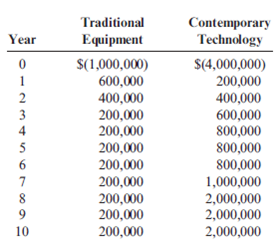

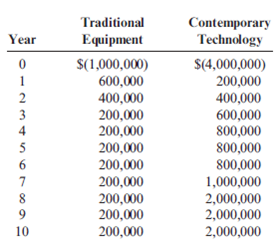

Sweeney Manufacturing has a plant where the equipment is essentially worn out. The equipment must be replaced, and Sweeney is considering two competing investment alternatives. The first alternative would replace the worn-out equipment with traditional production equipment; the second alternative uses contemporary technology and has computer-aided design and manufacturing capabilities. The investment and after-tax operating cash flows for each alternative are as follows:

The company uses a discount rate of 18 percent for all of its investments. The company's cost of capital is 14 percent.

Required:

1. Calculate the net present value for each investment using a discount rate of 18 percent.

2. Calculate the net present value for each investment using a discount rate of 14 percent.

3. Which rate should the company use to compute the net present value? Explain.

4. Now, assume that if the traditional equipment is purchased, the competitive position of the firm will deteriorate because of lower quality (relative to competitors who did automate). Marketing estimates that the loss in market share will decrease the projected net cash inflows by 50 percent for Years 3-10. Recalculate the NPV of the traditional equipment given this outcome. What is the decision now? Discuss the importance of assessing the effect of intangible and indirect benefits.

Sweeney Manufacturing has a plant where the equipment is essentially worn out. The equipment must be replaced, and Sweeney is considering two competing investment alternatives. The first alternative would replace the worn-out equipment with traditional production equipment; the second alternative uses contemporary technology and has computer-aided design and manufacturing capabilities. The investment and after-tax operating cash flows for each alternative are as follows:

The company uses a discount rate of 18 percent for all of its investments. The company's cost of capital is 14 percent.

Required:

1. Calculate the net present value for each investment using a discount rate of 18 percent.

2. Calculate the net present value for each investment using a discount rate of 14 percent.

3. Which rate should the company use to compute the net present value? Explain.

4. Now, assume that if the traditional equipment is purchased, the competitive position of the firm will deteriorate because of lower quality (relative to competitors who did automate). Marketing estimates that the loss in market share will decrease the projected net cash inflows by 50 percent for Years 3-10. Recalculate the NPV of the traditional equipment given this outcome. What is the decision now? Discuss the importance of assessing the effect of intangible and indirect benefits.

Unlock Deck

Unlock for access to all 47 flashcards in this deck.

Unlock Deck

k this deck

45

NPV Versus Internal Rate of Return

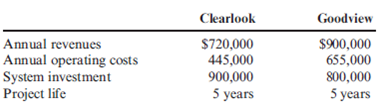

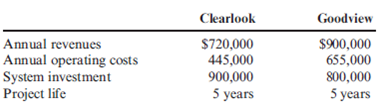

Keating Hospital is considering two different low-field MRI systems: the Clearlook System and the Goodview System. The projected annual revenues, annual costs, capital outlays, and project life for each system (in after-tax cash flows) are as follows:

Assume that the cost of capital for the company is 8 percent.

Required:

1. Calculate the NPV for the Clearlook System.

2. Calculate the NPV for the Goodview System. Which MRI system would be chosen?

3. What if Keating Hospital wants to know why IRR is not being used for the investment analysis? Calculate the IRR for each project and explain why it is not suitable for choosing among mutually exclusive investments.

Keating Hospital is considering two different low-field MRI systems: the Clearlook System and the Goodview System. The projected annual revenues, annual costs, capital outlays, and project life for each system (in after-tax cash flows) are as follows:

Assume that the cost of capital for the company is 8 percent.

Required:

1. Calculate the NPV for the Clearlook System.

2. Calculate the NPV for the Goodview System. Which MRI system would be chosen?

3. What if Keating Hospital wants to know why IRR is not being used for the investment analysis? Calculate the IRR for each project and explain why it is not suitable for choosing among mutually exclusive investments.

Unlock Deck

Unlock for access to all 47 flashcards in this deck.

Unlock Deck

k this deck

46