Deck 13: Control Systems: Financial and Human

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Unlock Deck

Sign up to unlock the cards in this deck!

Unlock Deck

Unlock Deck

1/29

Play

Full screen (f)

Deck 13: Control Systems: Financial and Human

1

Objective

To improve your skill at developing a control system for an organization/department.

Skills

The primary skills developed through this exercise are:

1. Management skill - decision making

2. AACSB competency - analytic

3. Management function - controlling

Situation

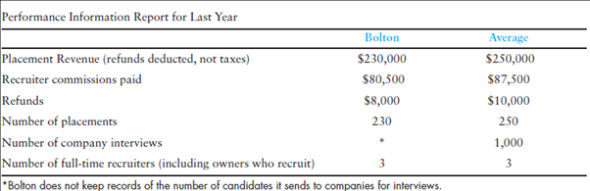

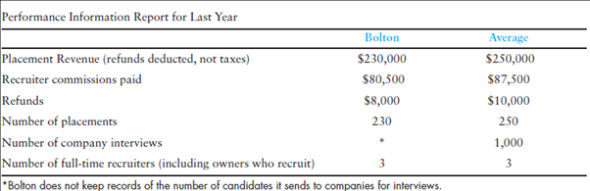

Marie Bolton owns and operates the Bolton Clerical Employment Agency. As the name indicates, her agency focuses on providing clerical employees to its business clients. It has a file of clerical employees looking for jobs or better jobs. When employers place job orders with the agency, the agency recruiter tries to find a person who fits the job specifications. The agency sends possible candidates to the employer. The employment agency charges the employer a fee only when one of its referred candidates is hired by the company. The fee is based on the employee's first-year salary. The average fee paid by employers is $1,000.

Each agency recruiter gets 35 percent of the fee charged as a salary. Pay is 100 percent commission. Refunds are made if the person placed does not stay on the job for three months.

Marie has two employees called recruiters. With only two employees, Marie is also a full-time recruiter. She does the management functions in addition to recruiting. Marie has no formal control methods because her two recruiters are very competent professionals who are paid only by commission; she places minimal restrictions on them. Marie is somewhat satisfied with the way her business is operating. However, through a professional association she found out that her business is not doing as well as the average employment agency. Being competitive by nature, Marie does not want to be below average.

Marie has asked you to set up a control system to help her improve her agency's performance. She has provided you with the following performance report, comparing her agency figures to those of the average agency. The professional association forecasts that revenues for next year will not increase for the industry.

Procedure

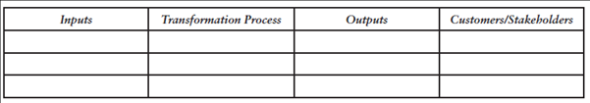

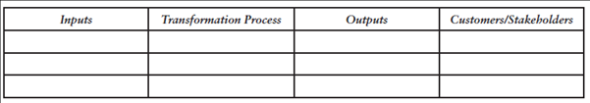

Identify the systems process for Bolton by identifying its primary inputs, transformation process, outputs, and customers/stakeholders:

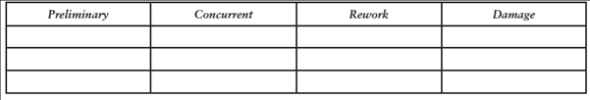

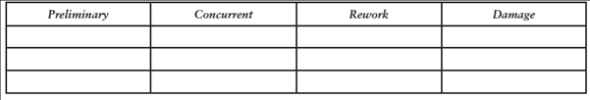

Identify major types of control for each stage of the systems process.

To set up a control system for Bolton, follow the steps in the control systems process.

Step 1. Setting Objectives and Standards

Marie's objective is to earn $250,000 in revenue for the next year, which is the industry average. Establish standards for the year that will enable Marie to reach her objective.

Quantity. Quantity of interviews per recruiter: ___________

Quantity of placements per recruiter: ___________

Calculate the number of additional interviews needed to meet the standard per recruiter: ___________

Calculate the percent increase: % ___________

Quality. State the dollar value of acceptable refunds per recruiter: $ ___________

State the corresponding number of refunds: ___________

Time. State the time period in which the quantity and quality standards should be met: ___________

Cost. State the cost based on commissions per recruiter:

$ ___________

Behavior. Identify any behaviors employees should change to help them meet the standards.

Step 2. Measuring Performance

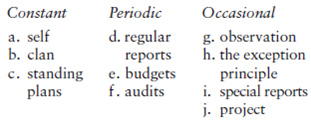

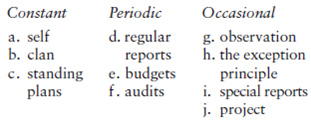

What are the critical success factors for employment agencies? Have you identified the critical success factors within your standards? If not, rework them. How often should Marie measure performance and what methods of control should she use?

Time frequency for measuring performance: ____________

Quantity of interviews per recruiter for time period: ____________

Quantity of placements per recruiter for time period: ____________

Specific control methods to use:

_________________________________________________________

_________________________________________________________

Step 3. Comparing Performance to Standards

How should Marie compare her agency's performance to her new standards?

Step 4. Correcting or Reinforcing

What type of corrective action should Marie take if standards are not being met or what type of reinforcement if they are?

_________________________________________________________

_________________________________________________________

Assume that Bolton does exactly meet the standard.

Calculate the rate of productivity for Bolton's past performance

(average agency): ___________________________

Calculate the rate of productivity for the new performance standard: ___________________________

Is there a change in productivity? ______________ yes ___________ no

If yes, by what percent did it increase or decrease? ___________________________

Base the inputs on recruiter commissions only.

Calculate the past commission per employee (average agency): _____________________

Calculate the new commission per employee: _____________________

What percent pay increase do recruiters get? _____________________

Do profits increase when the new standards are met? _____________________

How do you think the employees will react to your proposed control system? Do you think they will resist the control? Why or why not?

_________________________________________________________

_________________________________________________________

Apply It

What did I learn from this exercise? How will I use this knowledge in the future?

_________________________________________________________

_________________________________________________________

Your instructor may ask you to do this Skill Builder in class in a group. If so, the instructor will provide you with any necessary information or additional instructions.

To improve your skill at developing a control system for an organization/department.

Skills

The primary skills developed through this exercise are:

1. Management skill - decision making

2. AACSB competency - analytic

3. Management function - controlling

Situation

Marie Bolton owns and operates the Bolton Clerical Employment Agency. As the name indicates, her agency focuses on providing clerical employees to its business clients. It has a file of clerical employees looking for jobs or better jobs. When employers place job orders with the agency, the agency recruiter tries to find a person who fits the job specifications. The agency sends possible candidates to the employer. The employment agency charges the employer a fee only when one of its referred candidates is hired by the company. The fee is based on the employee's first-year salary. The average fee paid by employers is $1,000.

Each agency recruiter gets 35 percent of the fee charged as a salary. Pay is 100 percent commission. Refunds are made if the person placed does not stay on the job for three months.

Marie has two employees called recruiters. With only two employees, Marie is also a full-time recruiter. She does the management functions in addition to recruiting. Marie has no formal control methods because her two recruiters are very competent professionals who are paid only by commission; she places minimal restrictions on them. Marie is somewhat satisfied with the way her business is operating. However, through a professional association she found out that her business is not doing as well as the average employment agency. Being competitive by nature, Marie does not want to be below average.

Marie has asked you to set up a control system to help her improve her agency's performance. She has provided you with the following performance report, comparing her agency figures to those of the average agency. The professional association forecasts that revenues for next year will not increase for the industry.

Procedure

Identify the systems process for Bolton by identifying its primary inputs, transformation process, outputs, and customers/stakeholders:

Identify major types of control for each stage of the systems process.

To set up a control system for Bolton, follow the steps in the control systems process.

Step 1. Setting Objectives and Standards

Marie's objective is to earn $250,000 in revenue for the next year, which is the industry average. Establish standards for the year that will enable Marie to reach her objective.

Quantity. Quantity of interviews per recruiter: ___________

Quantity of placements per recruiter: ___________

Calculate the number of additional interviews needed to meet the standard per recruiter: ___________

Calculate the percent increase: % ___________

Quality. State the dollar value of acceptable refunds per recruiter: $ ___________

State the corresponding number of refunds: ___________

Time. State the time period in which the quantity and quality standards should be met: ___________

Cost. State the cost based on commissions per recruiter:

$ ___________

Behavior. Identify any behaviors employees should change to help them meet the standards.

Step 2. Measuring Performance

What are the critical success factors for employment agencies? Have you identified the critical success factors within your standards? If not, rework them. How often should Marie measure performance and what methods of control should she use?

Time frequency for measuring performance: ____________

Quantity of interviews per recruiter for time period: ____________

Quantity of placements per recruiter for time period: ____________

Specific control methods to use:

_________________________________________________________

_________________________________________________________

Step 3. Comparing Performance to Standards

How should Marie compare her agency's performance to her new standards?

Step 4. Correcting or Reinforcing

What type of corrective action should Marie take if standards are not being met or what type of reinforcement if they are?

_________________________________________________________

_________________________________________________________

Assume that Bolton does exactly meet the standard.

Calculate the rate of productivity for Bolton's past performance

(average agency): ___________________________

Calculate the rate of productivity for the new performance standard: ___________________________

Is there a change in productivity? ______________ yes ___________ no

If yes, by what percent did it increase or decrease? ___________________________

Base the inputs on recruiter commissions only.

Calculate the past commission per employee (average agency): _____________________

Calculate the new commission per employee: _____________________

What percent pay increase do recruiters get? _____________________

Do profits increase when the new standards are met? _____________________

How do you think the employees will react to your proposed control system? Do you think they will resist the control? Why or why not?

_________________________________________________________

_________________________________________________________

Apply It

What did I learn from this exercise? How will I use this knowledge in the future?

_________________________________________________________

_________________________________________________________

Your instructor may ask you to do this Skill Builder in class in a group. If so, the instructor will provide you with any necessary information or additional instructions.

not answer

2

Jack Chen started his small business about five years ago in the Garment District in New York City. Chen Clothes Manufacturing employs around 35 people. The five teams at Chen work in one big room in which all clothes are made. One of the teams makes custom shirts for quality men's clothing stores. Jack works in a separate office and spends most of his time on marketing, finance, and human resources management. He does not spend much time with the manufacturing employees. Team leaders are responsible for keeping team production records and hours worked, training team members, and helping them when there is a problem. Team leaders do not get involved with discipline.

Unlike some of his competitors, Jack does not want to run a sweatshop, so he pays employees a salary rather than a low piece rate for actual work performed. However, if employees don't produce an average of 48 shirts, they lose their jobs. Jack's employees have a higher rate of job satisfaction than competitors' employees do, and Chen has a quality reputation.

With all the competition, Jack is not making much money. He wants to get employees to produce more shirts. Jack thought about buying new machines as a capital expenditure, but he really did not have the money or the desire, because his current machines were working fine. Jack also considered changing to piece-rate pay. However, he figured that paying employees more to produce more would have an offsetting effect and would not benefit him much. He also feared that if he went to piece-rate pay he might have quality problems, which he did not want to risk. Jack prides himself on being ethical and socially responsible to all stakeholders.

Jack came up with the idea of setting a new quota in addition to the 48-shirt standard. Employees could leave work early once they had met the new 53-shirt quota. Jack figured that he was not pushing his employees too hard and that they could get out of work around a half-hour earlier each day.

Jack met with the employees in the shirt team and told them, "I want to try a new idea, which I think is fair to everyone, for the next two weeks. If you produce 53 shirts, you can go home for the day and get your full pay. I figure you can get out around 4:30 instead of 5 o'clock without having to rush your work. The same level of quality is required, and quality will be checked as usual. If you want, you can continue to produce 48 shirts and work the full eight hours." They discussed the new system, and they all liked the idea of working less hours for the same pay. If it did not work, they would go back to the old system.

On the Monday following the first week, Jack got his weekly production reports, which state the number of units made by each worker and the hours each employee worked, arranged by team. Jack got around to reading them after closing time, as usual. He went right to the shirt team report to see how the new system was working. Jack was happy to see that everyone was producing 53 shirts and getting out around 4:30. However, on Friday, Sue made 53 shirts and left at 2:30. Jack did not understand how this was possible. He decided to talk to Sue to see what was going on.

On Tuesday morning, Jack visited Sue at work and asked her how it was possible to get out at 2:30. Sue said, "All I did was adjust my machine and place this new gadget on it to speed it up. Plus I developed a new procedural sequence in which I make shirts. Watch how much faster I can sew now; especially placing buttons on is so much faster." Jack watched her in amazement as she made a shirt. He did not know what to say. He told her to keep up the good work and went back to his office.

As Jack walked back to his office, he wondered to himself: "Should I continue to let her leave that early? Do the other workers think it's fair for Sue to get out so much earlier than they do? This is only a two-week trial, subject to changes that are fair to everyone. What is the fair thing to do?"

Be sure that you are prepared to explain your answers to the following questions.

______ Jack's new leave-early control system had a meaningful direct effect on.

A) the income statement

B) the balance sheet

C) the cash flow

D) none of these

Unlike some of his competitors, Jack does not want to run a sweatshop, so he pays employees a salary rather than a low piece rate for actual work performed. However, if employees don't produce an average of 48 shirts, they lose their jobs. Jack's employees have a higher rate of job satisfaction than competitors' employees do, and Chen has a quality reputation.

With all the competition, Jack is not making much money. He wants to get employees to produce more shirts. Jack thought about buying new machines as a capital expenditure, but he really did not have the money or the desire, because his current machines were working fine. Jack also considered changing to piece-rate pay. However, he figured that paying employees more to produce more would have an offsetting effect and would not benefit him much. He also feared that if he went to piece-rate pay he might have quality problems, which he did not want to risk. Jack prides himself on being ethical and socially responsible to all stakeholders.

Jack came up with the idea of setting a new quota in addition to the 48-shirt standard. Employees could leave work early once they had met the new 53-shirt quota. Jack figured that he was not pushing his employees too hard and that they could get out of work around a half-hour earlier each day.

Jack met with the employees in the shirt team and told them, "I want to try a new idea, which I think is fair to everyone, for the next two weeks. If you produce 53 shirts, you can go home for the day and get your full pay. I figure you can get out around 4:30 instead of 5 o'clock without having to rush your work. The same level of quality is required, and quality will be checked as usual. If you want, you can continue to produce 48 shirts and work the full eight hours." They discussed the new system, and they all liked the idea of working less hours for the same pay. If it did not work, they would go back to the old system.

On the Monday following the first week, Jack got his weekly production reports, which state the number of units made by each worker and the hours each employee worked, arranged by team. Jack got around to reading them after closing time, as usual. He went right to the shirt team report to see how the new system was working. Jack was happy to see that everyone was producing 53 shirts and getting out around 4:30. However, on Friday, Sue made 53 shirts and left at 2:30. Jack did not understand how this was possible. He decided to talk to Sue to see what was going on.

On Tuesday morning, Jack visited Sue at work and asked her how it was possible to get out at 2:30. Sue said, "All I did was adjust my machine and place this new gadget on it to speed it up. Plus I developed a new procedural sequence in which I make shirts. Watch how much faster I can sew now; especially placing buttons on is so much faster." Jack watched her in amazement as she made a shirt. He did not know what to say. He told her to keep up the good work and went back to his office.

As Jack walked back to his office, he wondered to himself: "Should I continue to let her leave that early? Do the other workers think it's fair for Sue to get out so much earlier than they do? This is only a two-week trial, subject to changes that are fair to everyone. What is the fair thing to do?"

Be sure that you are prepared to explain your answers to the following questions.

______ Jack's new leave-early control system had a meaningful direct effect on.

A) the income statement

B) the balance sheet

C) the cash flow

D) none of these

The answer is (a) the income statement

Jack's new early leave method had a direct effect on the income statement because if an employee is leaving early then he is producing 53 shirts means increasing the productivity resulting in increased revenue from sales.

Jack's new early leave method had a direct effect on the income statement because if an employee is leaving early then he is producing 53 shirts means increasing the productivity resulting in increased revenue from sales.

3

The following critical-thinking questions can be used for class discussion and/or as written assignments to develop communication skills. Be sure to give complete explanations for all questions.

Apply the control systems process to your college education. What are your major objectives and standards? How do you measure and compare performance to your objectives and standards? What current and future corrective action have you taken? Do you reinforce your performance when meeting goals? If so, how?

Apply the control systems process to your college education. What are your major objectives and standards? How do you measure and compare performance to your objectives and standards? What current and future corrective action have you taken? Do you reinforce your performance when meeting goals? If so, how?

In the college, first we will set the objectives and standard of the college. In this we will let faculties and students know what is expected of them like the number of classes to be taken, minimum passing marks, the code of conduct which need to be followed, the cost of education, etc.

Next we will measure the performance of the college by interacting with the students and taking the feedback regarding the faculty members or by judging the performance of students.

Another control process is comparing the performance to standards. In this we will check that the standards set by the college and the results achieved are similar or not. And if the results are not same then what is the reason behind and what solution is required to correct them. For example, in college at inter college level in basketball competition the college could not win the trophy. The reason behind was that the coach was inefficient and incapable.

Lastly the correct action was taken which means a new coach was appointed so that the college could win the trophy. This is how performance was reinforced for meeting goals.

Next we will measure the performance of the college by interacting with the students and taking the feedback regarding the faculty members or by judging the performance of students.

Another control process is comparing the performance to standards. In this we will check that the standards set by the college and the results achieved are similar or not. And if the results are not same then what is the reason behind and what solution is required to correct them. For example, in college at inter college level in basketball competition the college could not win the trophy. The reason behind was that the coach was inefficient and incapable.

Lastly the correct action was taken which means a new coach was appointed so that the college could win the trophy. This is how performance was reinforced for meeting goals.

4

Jack Chen started his small business about five years ago in the Garment District in New York City. Chen Clothes Manufacturing employs around 35 people. The five teams at Chen work in one big room in which all clothes are made. One of the teams makes custom shirts for quality men's clothing stores. Jack works in a separate office and spends most of his time on marketing, finance, and human resources management. He does not spend much time with the manufacturing employees. Team leaders are responsible for keeping team production records and hours worked, training team members, and helping them when there is a problem. Team leaders do not get involved with discipline.

Unlike some of his competitors, Jack does not want to run a sweatshop, so he pays employees a salary rather than a low piece rate for actual work performed. However, if employees don't produce an average of 48 shirts, they lose their jobs. Jack's employees have a higher rate of job satisfaction than competitors' employees do, and Chen has a quality reputation.

With all the competition, Jack is not making much money. He wants to get employees to produce more shirts. Jack thought about buying new machines as a capital expenditure, but he really did not have the money or the desire, because his current machines were working fine. Jack also considered changing to piece-rate pay. However, he figured that paying employees more to produce more would have an offsetting effect and would not benefit him much. He also feared that if he went to piece-rate pay he might have quality problems, which he did not want to risk. Jack prides himself on being ethical and socially responsible to all stakeholders.

Jack came up with the idea of setting a new quota in addition to the 48-shirt standard. Employees could leave work early once they had met the new 53-shirt quota. Jack figured that he was not pushing his employees too hard and that they could get out of work around a half-hour earlier each day.

Jack met with the employees in the shirt team and told them, "I want to try a new idea, which I think is fair to everyone, for the next two weeks. If you produce 53 shirts, you can go home for the day and get your full pay. I figure you can get out around 4:30 instead of 5 o'clock without having to rush your work. The same level of quality is required, and quality will be checked as usual. If you want, you can continue to produce 48 shirts and work the full eight hours." They discussed the new system, and they all liked the idea of working less hours for the same pay. If it did not work, they would go back to the old system.

On the Monday following the first week, Jack got his weekly production reports, which state the number of units made by each worker and the hours each employee worked, arranged by team. Jack got around to reading them after closing time, as usual. He went right to the shirt team report to see how the new system was working. Jack was happy to see that everyone was producing 53 shirts and getting out around 4:30. However, on Friday, Sue made 53 shirts and left at 2:30. Jack did not understand how this was possible. He decided to talk to Sue to see what was going on.

On Tuesday morning, Jack visited Sue at work and asked her how it was possible to get out at 2:30. Sue said, "All I did was adjust my machine and place this new gadget on it to speed it up. Plus I developed a new procedural sequence in which I make shirts. Watch how much faster I can sew now; especially placing buttons on is so much faster." Jack watched her in amazement as she made a shirt. He did not know what to say. He told her to keep up the good work and went back to his office.

As Jack walked back to his office, he wondered to himself: "Should I continue to let her leave that early? Do the other workers think it's fair for Sue to get out so much earlier than they do? This is only a two-week trial, subject to changes that are fair to everyone. What is the fair thing to do?"

Be sure that you are prepared to explain your answers to the following questions.

______ Jack uses management by walking around (MBWA).

A) true

B) false

Unlike some of his competitors, Jack does not want to run a sweatshop, so he pays employees a salary rather than a low piece rate for actual work performed. However, if employees don't produce an average of 48 shirts, they lose their jobs. Jack's employees have a higher rate of job satisfaction than competitors' employees do, and Chen has a quality reputation.

With all the competition, Jack is not making much money. He wants to get employees to produce more shirts. Jack thought about buying new machines as a capital expenditure, but he really did not have the money or the desire, because his current machines were working fine. Jack also considered changing to piece-rate pay. However, he figured that paying employees more to produce more would have an offsetting effect and would not benefit him much. He also feared that if he went to piece-rate pay he might have quality problems, which he did not want to risk. Jack prides himself on being ethical and socially responsible to all stakeholders.

Jack came up with the idea of setting a new quota in addition to the 48-shirt standard. Employees could leave work early once they had met the new 53-shirt quota. Jack figured that he was not pushing his employees too hard and that they could get out of work around a half-hour earlier each day.

Jack met with the employees in the shirt team and told them, "I want to try a new idea, which I think is fair to everyone, for the next two weeks. If you produce 53 shirts, you can go home for the day and get your full pay. I figure you can get out around 4:30 instead of 5 o'clock without having to rush your work. The same level of quality is required, and quality will be checked as usual. If you want, you can continue to produce 48 shirts and work the full eight hours." They discussed the new system, and they all liked the idea of working less hours for the same pay. If it did not work, they would go back to the old system.

On the Monday following the first week, Jack got his weekly production reports, which state the number of units made by each worker and the hours each employee worked, arranged by team. Jack got around to reading them after closing time, as usual. He went right to the shirt team report to see how the new system was working. Jack was happy to see that everyone was producing 53 shirts and getting out around 4:30. However, on Friday, Sue made 53 shirts and left at 2:30. Jack did not understand how this was possible. He decided to talk to Sue to see what was going on.

On Tuesday morning, Jack visited Sue at work and asked her how it was possible to get out at 2:30. Sue said, "All I did was adjust my machine and place this new gadget on it to speed it up. Plus I developed a new procedural sequence in which I make shirts. Watch how much faster I can sew now; especially placing buttons on is so much faster." Jack watched her in amazement as she made a shirt. He did not know what to say. He told her to keep up the good work and went back to his office.

As Jack walked back to his office, he wondered to himself: "Should I continue to let her leave that early? Do the other workers think it's fair for Sue to get out so much earlier than they do? This is only a two-week trial, subject to changes that are fair to everyone. What is the fair thing to do?"

Be sure that you are prepared to explain your answers to the following questions.

______ Jack uses management by walking around (MBWA).

A) true

B) false

Unlock Deck

Unlock for access to all 29 flashcards in this deck.

Unlock Deck

k this deck

5

Jack Chen started his small business about five years ago in the Garment District in New York City. Chen Clothes Manufacturing employs around 35 people. The five teams at Chen work in one big room in which all clothes are made. One of the teams makes custom shirts for quality men's clothing stores. Jack works in a separate office and spends most of his time on marketing, finance, and human resources management. He does not spend much time with the manufacturing employees. Team leaders are responsible for keeping team production records and hours worked, training team members, and helping them when there is a problem. Team leaders do not get involved with discipline.

Unlike some of his competitors, Jack does not want to run a sweatshop, so he pays employees a salary rather than a low piece rate for actual work performed. However, if employees don't produce an average of 48 shirts, they lose their jobs. Jack's employees have a higher rate of job satisfaction than competitors' employees do, and Chen has a quality reputation.

With all the competition, Jack is not making much money. He wants to get employees to produce more shirts. Jack thought about buying new machines as a capital expenditure, but he really did not have the money or the desire, because his current machines were working fine. Jack also considered changing to piece-rate pay. However, he figured that paying employees more to produce more would have an offsetting effect and would not benefit him much. He also feared that if he went to piece-rate pay he might have quality problems, which he did not want to risk. Jack prides himself on being ethical and socially responsible to all stakeholders.

Jack came up with the idea of setting a new quota in addition to the 48-shirt standard. Employees could leave work early once they had met the new 53-shirt quota. Jack figured that he was not pushing his employees too hard and that they could get out of work around a half-hour earlier each day.

Jack met with the employees in the shirt team and told them, "I want to try a new idea, which I think is fair to everyone, for the next two weeks. If you produce 53 shirts, you can go home for the day and get your full pay. I figure you can get out around 4:30 instead of 5 o'clock without having to rush your work. The same level of quality is required, and quality will be checked as usual. If you want, you can continue to produce 48 shirts and work the full eight hours." They discussed the new system, and they all liked the idea of working less hours for the same pay. If it did not work, they would go back to the old system.

On the Monday following the first week, Jack got his weekly production reports, which state the number of units made by each worker and the hours each employee worked, arranged by team. Jack got around to reading them after closing time, as usual. He went right to the shirt team report to see how the new system was working. Jack was happy to see that everyone was producing 53 shirts and getting out around 4:30. However, on Friday, Sue made 53 shirts and left at 2:30. Jack did not understand how this was possible. He decided to talk to Sue to see what was going on.

On Tuesday morning, Jack visited Sue at work and asked her how it was possible to get out at 2:30. Sue said, "All I did was adjust my machine and place this new gadget on it to speed it up. Plus I developed a new procedural sequence in which I make shirts. Watch how much faster I can sew now; especially placing buttons on is so much faster." Jack watched her in amazement as she made a shirt. He did not know what to say. He told her to keep up the good work and went back to his office.

As Jack walked back to his office, he wondered to himself: "Should I continue to let her leave that early? Do the other workers think it's fair for Sue to get out so much earlier than they do? This is only a two-week trial, subject to changes that are fair to everyone. What is the fair thing to do?"

Be sure that you are prepared to explain your answers to the following questions.

______ A customer's returning a shirt because the sleeves are not the same length is an example of a ______ system control.

A) preliminary

B) concurrent

C) rework

D) damage

Unlike some of his competitors, Jack does not want to run a sweatshop, so he pays employees a salary rather than a low piece rate for actual work performed. However, if employees don't produce an average of 48 shirts, they lose their jobs. Jack's employees have a higher rate of job satisfaction than competitors' employees do, and Chen has a quality reputation.

With all the competition, Jack is not making much money. He wants to get employees to produce more shirts. Jack thought about buying new machines as a capital expenditure, but he really did not have the money or the desire, because his current machines were working fine. Jack also considered changing to piece-rate pay. However, he figured that paying employees more to produce more would have an offsetting effect and would not benefit him much. He also feared that if he went to piece-rate pay he might have quality problems, which he did not want to risk. Jack prides himself on being ethical and socially responsible to all stakeholders.

Jack came up with the idea of setting a new quota in addition to the 48-shirt standard. Employees could leave work early once they had met the new 53-shirt quota. Jack figured that he was not pushing his employees too hard and that they could get out of work around a half-hour earlier each day.

Jack met with the employees in the shirt team and told them, "I want to try a new idea, which I think is fair to everyone, for the next two weeks. If you produce 53 shirts, you can go home for the day and get your full pay. I figure you can get out around 4:30 instead of 5 o'clock without having to rush your work. The same level of quality is required, and quality will be checked as usual. If you want, you can continue to produce 48 shirts and work the full eight hours." They discussed the new system, and they all liked the idea of working less hours for the same pay. If it did not work, they would go back to the old system.

On the Monday following the first week, Jack got his weekly production reports, which state the number of units made by each worker and the hours each employee worked, arranged by team. Jack got around to reading them after closing time, as usual. He went right to the shirt team report to see how the new system was working. Jack was happy to see that everyone was producing 53 shirts and getting out around 4:30. However, on Friday, Sue made 53 shirts and left at 2:30. Jack did not understand how this was possible. He decided to talk to Sue to see what was going on.

On Tuesday morning, Jack visited Sue at work and asked her how it was possible to get out at 2:30. Sue said, "All I did was adjust my machine and place this new gadget on it to speed it up. Plus I developed a new procedural sequence in which I make shirts. Watch how much faster I can sew now; especially placing buttons on is so much faster." Jack watched her in amazement as she made a shirt. He did not know what to say. He told her to keep up the good work and went back to his office.

As Jack walked back to his office, he wondered to himself: "Should I continue to let her leave that early? Do the other workers think it's fair for Sue to get out so much earlier than they do? This is only a two-week trial, subject to changes that are fair to everyone. What is the fair thing to do?"

Be sure that you are prepared to explain your answers to the following questions.

______ A customer's returning a shirt because the sleeves are not the same length is an example of a ______ system control.

A) preliminary

B) concurrent

C) rework

D) damage

Unlock Deck

Unlock for access to all 29 flashcards in this deck.

Unlock Deck

k this deck

6

Jack Chen started his small business about five years ago in the Garment District in New York City. Chen Clothes Manufacturing employs around 35 people. The five teams at Chen work in one big room in which all clothes are made. One of the teams makes custom shirts for quality men's clothing stores. Jack works in a separate office and spends most of his time on marketing, finance, and human resources management. He does not spend much time with the manufacturing employees. Team leaders are responsible for keeping team production records and hours worked, training team members, and helping them when there is a problem. Team leaders do not get involved with discipline.

Unlike some of his competitors, Jack does not want to run a sweatshop, so he pays employees a salary rather than a low piece rate for actual work performed. However, if employees don't produce an average of 48 shirts, they lose their jobs. Jack's employees have a higher rate of job satisfaction than competitors' employees do, and Chen has a quality reputation.

With all the competition, Jack is not making much money. He wants to get employees to produce more shirts. Jack thought about buying new machines as a capital expenditure, but he really did not have the money or the desire, because his current machines were working fine. Jack also considered changing to piece-rate pay. However, he figured that paying employees more to produce more would have an offsetting effect and would not benefit him much. He also feared that if he went to piece-rate pay he might have quality problems, which he did not want to risk. Jack prides himself on being ethical and socially responsible to all stakeholders.

Jack came up with the idea of setting a new quota in addition to the 48-shirt standard. Employees could leave work early once they had met the new 53-shirt quota. Jack figured that he was not pushing his employees too hard and that they could get out of work around a half-hour earlier each day.

Jack met with the employees in the shirt team and told them, "I want to try a new idea, which I think is fair to everyone, for the next two weeks. If you produce 53 shirts, you can go home for the day and get your full pay. I figure you can get out around 4:30 instead of 5 o'clock without having to rush your work. The same level of quality is required, and quality will be checked as usual. If you want, you can continue to produce 48 shirts and work the full eight hours." They discussed the new system, and they all liked the idea of working less hours for the same pay. If it did not work, they would go back to the old system.

On the Monday following the first week, Jack got his weekly production reports, which state the number of units made by each worker and the hours each employee worked, arranged by team. Jack got around to reading them after closing time, as usual. He went right to the shirt team report to see how the new system was working. Jack was happy to see that everyone was producing 53 shirts and getting out around 4:30. However, on Friday, Sue made 53 shirts and left at 2:30. Jack did not understand how this was possible. He decided to talk to Sue to see what was going on.

On Tuesday morning, Jack visited Sue at work and asked her how it was possible to get out at 2:30. Sue said, "All I did was adjust my machine and place this new gadget on it to speed it up. Plus I developed a new procedural sequence in which I make shirts. Watch how much faster I can sew now; especially placing buttons on is so much faster." Jack watched her in amazement as she made a shirt. He did not know what to say. He told her to keep up the good work and went back to his office.

As Jack walked back to his office, he wondered to himself: "Should I continue to let her leave that early? Do the other workers think it's fair for Sue to get out so much earlier than they do? This is only a two-week trial, subject to changes that are fair to everyone. What is the fair thing to do?"

Be sure that you are prepared to explain your answers to the following questions.

Is there any potential problems with Sue's adjusting of her machine?

Unlike some of his competitors, Jack does not want to run a sweatshop, so he pays employees a salary rather than a low piece rate for actual work performed. However, if employees don't produce an average of 48 shirts, they lose their jobs. Jack's employees have a higher rate of job satisfaction than competitors' employees do, and Chen has a quality reputation.

With all the competition, Jack is not making much money. He wants to get employees to produce more shirts. Jack thought about buying new machines as a capital expenditure, but he really did not have the money or the desire, because his current machines were working fine. Jack also considered changing to piece-rate pay. However, he figured that paying employees more to produce more would have an offsetting effect and would not benefit him much. He also feared that if he went to piece-rate pay he might have quality problems, which he did not want to risk. Jack prides himself on being ethical and socially responsible to all stakeholders.

Jack came up with the idea of setting a new quota in addition to the 48-shirt standard. Employees could leave work early once they had met the new 53-shirt quota. Jack figured that he was not pushing his employees too hard and that they could get out of work around a half-hour earlier each day.

Jack met with the employees in the shirt team and told them, "I want to try a new idea, which I think is fair to everyone, for the next two weeks. If you produce 53 shirts, you can go home for the day and get your full pay. I figure you can get out around 4:30 instead of 5 o'clock without having to rush your work. The same level of quality is required, and quality will be checked as usual. If you want, you can continue to produce 48 shirts and work the full eight hours." They discussed the new system, and they all liked the idea of working less hours for the same pay. If it did not work, they would go back to the old system.

On the Monday following the first week, Jack got his weekly production reports, which state the number of units made by each worker and the hours each employee worked, arranged by team. Jack got around to reading them after closing time, as usual. He went right to the shirt team report to see how the new system was working. Jack was happy to see that everyone was producing 53 shirts and getting out around 4:30. However, on Friday, Sue made 53 shirts and left at 2:30. Jack did not understand how this was possible. He decided to talk to Sue to see what was going on.

On Tuesday morning, Jack visited Sue at work and asked her how it was possible to get out at 2:30. Sue said, "All I did was adjust my machine and place this new gadget on it to speed it up. Plus I developed a new procedural sequence in which I make shirts. Watch how much faster I can sew now; especially placing buttons on is so much faster." Jack watched her in amazement as she made a shirt. He did not know what to say. He told her to keep up the good work and went back to his office.

As Jack walked back to his office, he wondered to himself: "Should I continue to let her leave that early? Do the other workers think it's fair for Sue to get out so much earlier than they do? This is only a two-week trial, subject to changes that are fair to everyone. What is the fair thing to do?"

Be sure that you are prepared to explain your answers to the following questions.

Is there any potential problems with Sue's adjusting of her machine?

Unlock Deck

Unlock for access to all 29 flashcards in this deck.

Unlock Deck

k this deck

7

Objective

To develop your skill at improving performance through

coaching.

Skills

The primary skills developed through this exercise are:

1. Management skill - interpersonal

2. AACSB competency - communication

3. Management function - controlling

Procedure 1 (2-4 minutes)

Break into groups of three. Make some groups of two, if necessary. Each member selects one of the following three situations in which to be the manager and a different one in which to be the employee. In each situation, the employee knows the standing plans; he or she is not motivated to follow them. You will take turns coaching and being coached.

Three Problem Employee Situations

1. Employee 1 is a clerical worker. The person uses files, as do the other ten employees in the department. The employees all know that they are supposed to return the files when they are finished so that others can find them when they need them. Employees should have only one file out at a time. The supervisor notices that Employee 1 has five files on the desk, and another employee is looking for one of them. The supervisor thinks that Employee 1 will complain about the heavy workload as an excuse for having more than one file out at a time.

2. Employee 2 is a server in an ice-cream shop. The employee knows that the tables should be cleaned up quickly after customers leave so that new customers do not have to sit at dirty tables. It's a busy night. The supervisor finds dirty dishes on two of this employee's occupied tables. Employee 2 is socializing with some friends at one of the tables. Employees are supposed to be friendly; Employee 2 will probably use this as an excuse for the dirty tables.

3. Employee 3 is an auto technician. All employees at the garage where this person works know that they are supposed to put a paper mat on the floor of each car so that the carpets don't get dirty. When the service supervisor got into a car Employee 3 repaired, the car did not have a mat and there was grease on the carpet. Employee 3 does excellent work and will probably make reference to this fact when coached.

Procedure 2 (3-7 minutes)

Prepare for coaching to improve performance. Below, each group member writes an outline of what he or she will say when coaching Employee 1, 2, or 3, following the steps below:

1. Describe current performance.

_________________________________________________________

_________________________________________________________

2. Describe desired performance. (Don't forget to have the employee state why it is important.)

_________________________________________________________

_________________________________________________________

3. Get a commitment to the change.

_________________________________________________________

_________________________________________________________

4. Follow up.

_________________________________________________________

_________________________________________________________

Procedure 3 (5-8 minutes)

Role-Playing. The manager of Employee 1, the clerical worker, coaches him or her as planned. (Use the actual name of the group member playing Employee 1.) Talk- do not read your written plan. Employee 1, put yourself in the worker's position. You work hard; there is a lot of pressure to work fast. It's easier when you have more than one file. Refer to the workload while being coached. Both the manager and the employee will have to ad lib. The person not playing a role is the observer. He or she makes notes on the observer form below. Try to make positive comments and point out areas for improvement. Give the manager alternative suggestions about what he or she could have said to improve the coaching session.

Observer Form

1. How well did the manager describe current behavior?

_________________________________________________________

_________________________________________________________

2. How well did the manager describe desired behavior? Did the employee state why the behavior is important?

_________________________________________________________

_________________________________________________________

3. How successful was the manager at getting a commitment to the change? Do you think the employee will change?

_________________________________________________________

_________________________________________________________

4. How well did the manager describe how he or she was going to follow up to ensure that the employee performed the desired behavior?

_________________________________________________________

_________________________________________________________

Feedback. The observer leads a discussion of how well the manager coached the employee. (This should be a discussion, not a lecture.) Focus on what the manager did well and how the manager could improve. The employee should also give feedback on how he or she felt and what might have been more effective in getting him or her to change. Do not go on to the next interview until you are told to do so. If you finish early, wait for the others to finish.

Procedure 4 (5-8 minutes)

Same as procedure 3, but change roles so that Employee 2, the server, is coached. Employee 2 should make a comment about the importance of talking to customers to make them feel welcome. The job is not much fun if you can't talk to your friends.

Procedure 5 (5-8 minutes)

Same as procedure 3, but change roles so that Employee 3, the auto technician, is coached. Employee 3 should comment on the excellent work he or she does.

Apply It

What did I learn from this experience? How will I use this knowledge in the future?

_________________________________________________________

_________________________________________________________

To develop your skill at improving performance through

coaching.

Skills

The primary skills developed through this exercise are:

1. Management skill - interpersonal

2. AACSB competency - communication

3. Management function - controlling

Procedure 1 (2-4 minutes)

Break into groups of three. Make some groups of two, if necessary. Each member selects one of the following three situations in which to be the manager and a different one in which to be the employee. In each situation, the employee knows the standing plans; he or she is not motivated to follow them. You will take turns coaching and being coached.

Three Problem Employee Situations

1. Employee 1 is a clerical worker. The person uses files, as do the other ten employees in the department. The employees all know that they are supposed to return the files when they are finished so that others can find them when they need them. Employees should have only one file out at a time. The supervisor notices that Employee 1 has five files on the desk, and another employee is looking for one of them. The supervisor thinks that Employee 1 will complain about the heavy workload as an excuse for having more than one file out at a time.

2. Employee 2 is a server in an ice-cream shop. The employee knows that the tables should be cleaned up quickly after customers leave so that new customers do not have to sit at dirty tables. It's a busy night. The supervisor finds dirty dishes on two of this employee's occupied tables. Employee 2 is socializing with some friends at one of the tables. Employees are supposed to be friendly; Employee 2 will probably use this as an excuse for the dirty tables.

3. Employee 3 is an auto technician. All employees at the garage where this person works know that they are supposed to put a paper mat on the floor of each car so that the carpets don't get dirty. When the service supervisor got into a car Employee 3 repaired, the car did not have a mat and there was grease on the carpet. Employee 3 does excellent work and will probably make reference to this fact when coached.

Procedure 2 (3-7 minutes)

Prepare for coaching to improve performance. Below, each group member writes an outline of what he or she will say when coaching Employee 1, 2, or 3, following the steps below:

1. Describe current performance.

_________________________________________________________

_________________________________________________________

2. Describe desired performance. (Don't forget to have the employee state why it is important.)

_________________________________________________________

_________________________________________________________

3. Get a commitment to the change.

_________________________________________________________

_________________________________________________________

4. Follow up.

_________________________________________________________

_________________________________________________________

Procedure 3 (5-8 minutes)

Role-Playing. The manager of Employee 1, the clerical worker, coaches him or her as planned. (Use the actual name of the group member playing Employee 1.) Talk- do not read your written plan. Employee 1, put yourself in the worker's position. You work hard; there is a lot of pressure to work fast. It's easier when you have more than one file. Refer to the workload while being coached. Both the manager and the employee will have to ad lib. The person not playing a role is the observer. He or she makes notes on the observer form below. Try to make positive comments and point out areas for improvement. Give the manager alternative suggestions about what he or she could have said to improve the coaching session.

Observer Form

1. How well did the manager describe current behavior?

_________________________________________________________

_________________________________________________________

2. How well did the manager describe desired behavior? Did the employee state why the behavior is important?

_________________________________________________________

_________________________________________________________

3. How successful was the manager at getting a commitment to the change? Do you think the employee will change?

_________________________________________________________

_________________________________________________________

4. How well did the manager describe how he or she was going to follow up to ensure that the employee performed the desired behavior?

_________________________________________________________

_________________________________________________________

Feedback. The observer leads a discussion of how well the manager coached the employee. (This should be a discussion, not a lecture.) Focus on what the manager did well and how the manager could improve. The employee should also give feedback on how he or she felt and what might have been more effective in getting him or her to change. Do not go on to the next interview until you are told to do so. If you finish early, wait for the others to finish.

Procedure 4 (5-8 minutes)

Same as procedure 3, but change roles so that Employee 2, the server, is coached. Employee 2 should make a comment about the importance of talking to customers to make them feel welcome. The job is not much fun if you can't talk to your friends.

Procedure 5 (5-8 minutes)

Same as procedure 3, but change roles so that Employee 3, the auto technician, is coached. Employee 3 should comment on the excellent work he or she does.

Apply It

What did I learn from this experience? How will I use this knowledge in the future?

_________________________________________________________

_________________________________________________________

Unlock Deck

Unlock for access to all 29 flashcards in this deck.

Unlock Deck

k this deck

8

Jack Chen started his small business about five years ago in the Garment District in New York City. Chen Clothes Manufacturing employs around 35 people. The five teams at Chen work in one big room in which all clothes are made. One of the teams makes custom shirts for quality men's clothing stores. Jack works in a separate office and spends most of his time on marketing, finance, and human resources management. He does not spend much time with the manufacturing employees. Team leaders are responsible for keeping team production records and hours worked, training team members, and helping them when there is a problem. Team leaders do not get involved with discipline.

Unlike some of his competitors, Jack does not want to run a sweatshop, so he pays employees a salary rather than a low piece rate for actual work performed. However, if employees don't produce an average of 48 shirts, they lose their jobs. Jack's employees have a higher rate of job satisfaction than competitors' employees do, and Chen has a quality reputation.

With all the competition, Jack is not making much money. He wants to get employees to produce more shirts. Jack thought about buying new machines as a capital expenditure, but he really did not have the money or the desire, because his current machines were working fine. Jack also considered changing to piece-rate pay. However, he figured that paying employees more to produce more would have an offsetting effect and would not benefit him much. He also feared that if he went to piece-rate pay he might have quality problems, which he did not want to risk. Jack prides himself on being ethical and socially responsible to all stakeholders.

Jack came up with the idea of setting a new quota in addition to the 48-shirt standard. Employees could leave work early once they had met the new 53-shirt quota. Jack figured that he was not pushing his employees too hard and that they could get out of work around a half-hour earlier each day.

Jack met with the employees in the shirt team and told them, "I want to try a new idea, which I think is fair to everyone, for the next two weeks. If you produce 53 shirts, you can go home for the day and get your full pay. I figure you can get out around 4:30 instead of 5 o'clock without having to rush your work. The same level of quality is required, and quality will be checked as usual. If you want, you can continue to produce 48 shirts and work the full eight hours." They discussed the new system, and they all liked the idea of working less hours for the same pay. If it did not work, they would go back to the old system.

On the Monday following the first week, Jack got his weekly production reports, which state the number of units made by each worker and the hours each employee worked, arranged by team. Jack got around to reading them after closing time, as usual. He went right to the shirt team report to see how the new system was working. Jack was happy to see that everyone was producing 53 shirts and getting out around 4:30. However, on Friday, Sue made 53 shirts and left at 2:30. Jack did not understand how this was possible. He decided to talk to Sue to see what was going on.

On Tuesday morning, Jack visited Sue at work and asked her how it was possible to get out at 2:30. Sue said, "All I did was adjust my machine and place this new gadget on it to speed it up. Plus I developed a new procedural sequence in which I make shirts. Watch how much faster I can sew now; especially placing buttons on is so much faster." Jack watched her in amazement as she made a shirt. He did not know what to say. He told her to keep up the good work and went back to his office.

As Jack walked back to his office, he wondered to himself: "Should I continue to let her leave that early? Do the other workers think it's fair for Sue to get out so much earlier than they do? This is only a two-week trial, subject to changes that are fair to everyone. What is the fair thing to do?"

Be sure that you are prepared to explain your answers to the following questions.

Should Jack keep the control system the way it is now and continue to let Sue leave two hours earlier than the other employees? If not, what should he do?

Unlike some of his competitors, Jack does not want to run a sweatshop, so he pays employees a salary rather than a low piece rate for actual work performed. However, if employees don't produce an average of 48 shirts, they lose their jobs. Jack's employees have a higher rate of job satisfaction than competitors' employees do, and Chen has a quality reputation.

With all the competition, Jack is not making much money. He wants to get employees to produce more shirts. Jack thought about buying new machines as a capital expenditure, but he really did not have the money or the desire, because his current machines were working fine. Jack also considered changing to piece-rate pay. However, he figured that paying employees more to produce more would have an offsetting effect and would not benefit him much. He also feared that if he went to piece-rate pay he might have quality problems, which he did not want to risk. Jack prides himself on being ethical and socially responsible to all stakeholders.

Jack came up with the idea of setting a new quota in addition to the 48-shirt standard. Employees could leave work early once they had met the new 53-shirt quota. Jack figured that he was not pushing his employees too hard and that they could get out of work around a half-hour earlier each day.

Jack met with the employees in the shirt team and told them, "I want to try a new idea, which I think is fair to everyone, for the next two weeks. If you produce 53 shirts, you can go home for the day and get your full pay. I figure you can get out around 4:30 instead of 5 o'clock without having to rush your work. The same level of quality is required, and quality will be checked as usual. If you want, you can continue to produce 48 shirts and work the full eight hours." They discussed the new system, and they all liked the idea of working less hours for the same pay. If it did not work, they would go back to the old system.

On the Monday following the first week, Jack got his weekly production reports, which state the number of units made by each worker and the hours each employee worked, arranged by team. Jack got around to reading them after closing time, as usual. He went right to the shirt team report to see how the new system was working. Jack was happy to see that everyone was producing 53 shirts and getting out around 4:30. However, on Friday, Sue made 53 shirts and left at 2:30. Jack did not understand how this was possible. He decided to talk to Sue to see what was going on.

On Tuesday morning, Jack visited Sue at work and asked her how it was possible to get out at 2:30. Sue said, "All I did was adjust my machine and place this new gadget on it to speed it up. Plus I developed a new procedural sequence in which I make shirts. Watch how much faster I can sew now; especially placing buttons on is so much faster." Jack watched her in amazement as she made a shirt. He did not know what to say. He told her to keep up the good work and went back to his office.

As Jack walked back to his office, he wondered to himself: "Should I continue to let her leave that early? Do the other workers think it's fair for Sue to get out so much earlier than they do? This is only a two-week trial, subject to changes that are fair to everyone. What is the fair thing to do?"

Be sure that you are prepared to explain your answers to the following questions.

Should Jack keep the control system the way it is now and continue to let Sue leave two hours earlier than the other employees? If not, what should he do?

Unlock Deck

Unlock for access to all 29 flashcards in this deck.

Unlock Deck

k this deck

9

The following critical-thinking questions can be used for class discussion and/or as written assignments to develop communication skills. Be sure to give complete explanations for all questions.

Employees tend to resist control and sometimes break the rules. Give examples of things you or others have done to resist controls

Employees tend to resist control and sometimes break the rules. Give examples of things you or others have done to resist controls

Unlock Deck

Unlock for access to all 29 flashcards in this deck.

Unlock Deck

k this deck

10

Jack Chen started his small business about five years ago in the Garment District in New York City. Chen Clothes Manufacturing employs around 35 people. The five teams at Chen work in one big room in which all clothes are made. One of the teams makes custom shirts for quality men's clothing stores. Jack works in a separate office and spends most of his time on marketing, finance, and human resources management. He does not spend much time with the manufacturing employees. Team leaders are responsible for keeping team production records and hours worked, training team members, and helping them when there is a problem. Team leaders do not get involved with discipline.

Unlike some of his competitors, Jack does not want to run a sweatshop, so he pays employees a salary rather than a low piece rate for actual work performed. However, if employees don't produce an average of 48 shirts, they lose their jobs. Jack's employees have a higher rate of job satisfaction than competitors' employees do, and Chen has a quality reputation.

With all the competition, Jack is not making much money. He wants to get employees to produce more shirts. Jack thought about buying new machines as a capital expenditure, but he really did not have the money or the desire, because his current machines were working fine. Jack also considered changing to piece-rate pay. However, he figured that paying employees more to produce more would have an offsetting effect and would not benefit him much. He also feared that if he went to piece-rate pay he might have quality problems, which he did not want to risk. Jack prides himself on being ethical and socially responsible to all stakeholders.

Jack came up with the idea of setting a new quota in addition to the 48-shirt standard. Employees could leave work early once they had met the new 53-shirt quota. Jack figured that he was not pushing his employees too hard and that they could get out of work around a half-hour earlier each day.

Jack met with the employees in the shirt team and told them, "I want to try a new idea, which I think is fair to everyone, for the next two weeks. If you produce 53 shirts, you can go home for the day and get your full pay. I figure you can get out around 4:30 instead of 5 o'clock without having to rush your work. The same level of quality is required, and quality will be checked as usual. If you want, you can continue to produce 48 shirts and work the full eight hours." They discussed the new system, and they all liked the idea of working less hours for the same pay. If it did not work, they would go back to the old system.

On the Monday following the first week, Jack got his weekly production reports, which state the number of units made by each worker and the hours each employee worked, arranged by team. Jack got around to reading them after closing time, as usual. He went right to the shirt team report to see how the new system was working. Jack was happy to see that everyone was producing 53 shirts and getting out around 4:30. However, on Friday, Sue made 53 shirts and left at 2:30. Jack did not understand how this was possible. He decided to talk to Sue to see what was going on.

On Tuesday morning, Jack visited Sue at work and asked her how it was possible to get out at 2:30. Sue said, "All I did was adjust my machine and place this new gadget on it to speed it up. Plus I developed a new procedural sequence in which I make shirts. Watch how much faster I can sew now; especially placing buttons on is so much faster." Jack watched her in amazement as she made a shirt. He did not know what to say. He told her to keep up the good work and went back to his office.

As Jack walked back to his office, he wondered to himself: "Should I continue to let her leave that early? Do the other workers think it's fair for Sue to get out so much earlier than they do? This is only a two-week trial, subject to changes that are fair to everyone. What is the fair thing to do?"

Be sure that you are prepared to explain your answers to the following questions.

Does the increased production/productivity pose any potential threat to employees? Explain

Unlike some of his competitors, Jack does not want to run a sweatshop, so he pays employees a salary rather than a low piece rate for actual work performed. However, if employees don't produce an average of 48 shirts, they lose their jobs. Jack's employees have a higher rate of job satisfaction than competitors' employees do, and Chen has a quality reputation.

With all the competition, Jack is not making much money. He wants to get employees to produce more shirts. Jack thought about buying new machines as a capital expenditure, but he really did not have the money or the desire, because his current machines were working fine. Jack also considered changing to piece-rate pay. However, he figured that paying employees more to produce more would have an offsetting effect and would not benefit him much. He also feared that if he went to piece-rate pay he might have quality problems, which he did not want to risk. Jack prides himself on being ethical and socially responsible to all stakeholders.

Jack came up with the idea of setting a new quota in addition to the 48-shirt standard. Employees could leave work early once they had met the new 53-shirt quota. Jack figured that he was not pushing his employees too hard and that they could get out of work around a half-hour earlier each day.

Jack met with the employees in the shirt team and told them, "I want to try a new idea, which I think is fair to everyone, for the next two weeks. If you produce 53 shirts, you can go home for the day and get your full pay. I figure you can get out around 4:30 instead of 5 o'clock without having to rush your work. The same level of quality is required, and quality will be checked as usual. If you want, you can continue to produce 48 shirts and work the full eight hours." They discussed the new system, and they all liked the idea of working less hours for the same pay. If it did not work, they would go back to the old system.

On the Monday following the first week, Jack got his weekly production reports, which state the number of units made by each worker and the hours each employee worked, arranged by team. Jack got around to reading them after closing time, as usual. He went right to the shirt team report to see how the new system was working. Jack was happy to see that everyone was producing 53 shirts and getting out around 4:30. However, on Friday, Sue made 53 shirts and left at 2:30. Jack did not understand how this was possible. He decided to talk to Sue to see what was going on.

On Tuesday morning, Jack visited Sue at work and asked her how it was possible to get out at 2:30. Sue said, "All I did was adjust my machine and place this new gadget on it to speed it up. Plus I developed a new procedural sequence in which I make shirts. Watch how much faster I can sew now; especially placing buttons on is so much faster." Jack watched her in amazement as she made a shirt. He did not know what to say. He told her to keep up the good work and went back to his office.

As Jack walked back to his office, he wondered to himself: "Should I continue to let her leave that early? Do the other workers think it's fair for Sue to get out so much earlier than they do? This is only a two-week trial, subject to changes that are fair to everyone. What is the fair thing to do?"

Be sure that you are prepared to explain your answers to the following questions.

Does the increased production/productivity pose any potential threat to employees? Explain

Unlock Deck

Unlock for access to all 29 flashcards in this deck.

Unlock Deck

k this deck

11

Jack Chen started his small business about five years ago in the Garment District in New York City. Chen Clothes Manufacturing employs around 35 people. The five teams at Chen work in one big room in which all clothes are made. One of the teams makes custom shirts for quality men's clothing stores. Jack works in a separate office and spends most of his time on marketing, finance, and human resources management. He does not spend much time with the manufacturing employees. Team leaders are responsible for keeping team production records and hours worked, training team members, and helping them when there is a problem. Team leaders do not get involved with discipline.

Unlike some of his competitors, Jack does not want to run a sweatshop, so he pays employees a salary rather than a low piece rate for actual work performed. However, if employees don't produce an average of 48 shirts, they lose their jobs. Jack's employees have a higher rate of job satisfaction than competitors' employees do, and Chen has a quality reputation.

With all the competition, Jack is not making much money. He wants to get employees to produce more shirts. Jack thought about buying new machines as a capital expenditure, but he really did not have the money or the desire, because his current machines were working fine. Jack also considered changing to piece-rate pay. However, he figured that paying employees more to produce more would have an offsetting effect and would not benefit him much. He also feared that if he went to piece-rate pay he might have quality problems, which he did not want to risk. Jack prides himself on being ethical and socially responsible to all stakeholders.

Jack came up with the idea of setting a new quota in addition to the 48-shirt standard. Employees could leave work early once they had met the new 53-shirt quota. Jack figured that he was not pushing his employees too hard and that they could get out of work around a half-hour earlier each day.

Jack met with the employees in the shirt team and told them, "I want to try a new idea, which I think is fair to everyone, for the next two weeks. If you produce 53 shirts, you can go home for the day and get your full pay. I figure you can get out around 4:30 instead of 5 o'clock without having to rush your work. The same level of quality is required, and quality will be checked as usual. If you want, you can continue to produce 48 shirts and work the full eight hours." They discussed the new system, and they all liked the idea of working less hours for the same pay. If it did not work, they would go back to the old system.

On the Monday following the first week, Jack got his weekly production reports, which state the number of units made by each worker and the hours each employee worked, arranged by team. Jack got around to reading them after closing time, as usual. He went right to the shirt team report to see how the new system was working. Jack was happy to see that everyone was producing 53 shirts and getting out around 4:30. However, on Friday, Sue made 53 shirts and left at 2:30. Jack did not understand how this was possible. He decided to talk to Sue to see what was going on.

On Tuesday morning, Jack visited Sue at work and asked her how it was possible to get out at 2:30. Sue said, "All I did was adjust my machine and place this new gadget on it to speed it up. Plus I developed a new procedural sequence in which I make shirts. Watch how much faster I can sew now; especially placing buttons on is so much faster." Jack watched her in amazement as she made a shirt. He did not know what to say. He told her to keep up the good work and went back to his office.

As Jack walked back to his office, he wondered to himself: "Should I continue to let her leave that early? Do the other workers think it's fair for Sue to get out so much earlier than they do? This is only a two-week trial, subject to changes that are fair to everyone. What is the fair thing to do?"

Be sure that you are prepared to explain your answers to the following questions.