Deck 2: Operations and Supply Chain Strategy

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Unlock Deck

Sign up to unlock the cards in this deck!

Unlock Deck

Unlock Deck

1/23

Play

Full screen (f)

Deck 2: Operations and Supply Chain Strategy

1

Steinway Sons Piano

Steinway pianos have long been the premier brand among serious pianists.Franz Liszt called his Steinway "a glorious masterpiece." Gioacchino Rossini, a 19th-century composer, described the Steinway sound as "great as thunder, sweet as the fluting of a nightingale." In short, Steinway's product is the piano of choice for the vast majority of concert artists.

From the beginning, Steinways were a work of art.José Feghali, a classical pianist, illustrated this point when he remarked, "With the best pianos, you can walk into a room with 10 pianos and it's like playing 10 different instruments." The prices of the 5,000 or so pianos that Steinway produces each year range from $10,000 for an upright to $62,000 for a special-order concert grand piano.

In the 1990s, Steinway Sons encountered some problems.John and Robert Birmingham purchased the firm in a $53.5 million leveraged buyout deal.John's previous experience involved making plastic windows for envelopes.Robert's most recent experience was with a mail-order business selling products with bear themes.Robert Birmingham said that they were delighted with the purchase because they viewed Steinway as a "great opportunity" given the firm's "great name and great tradition."

Steinway's craft-driven organization had not fared too well under its previous owner, CBS.The turmoil resulting from frequent management changes had reduced the consistency of Steinway's cherished reputation.Dealers complained that Steinways weren't of the same quality any more-they were often badly tuned and had sloppy finishes.Finally, in 1978, CBS hired a long-time piano industry executive who helped restore much of Steinway's reputation.

Now, a new set of outsiders owned the company.That the owners liked classical music did not assure Steinway's 1,000 employees that they knew how to make classic quality pianos.To make matters worse, the Birmingham brothers were now talking about using their "extensive manufacturing experience" to streamline operations.One commented that the operation was "too reliant on a few craftsmen."

Soon modern manufacturing methods crept into the Steinway operation.A computer control system was introduced to keep track of parts and inventory.Eight million dollars was invested in new equipment to make the quality of small parts, such as piano hammers, more consistent.The loose-leaf binders that specified how pianos were to be built were replaced with engineering drawings.By the late 1980s, Steinway had entered the 20th century.John Birmingham lamented: "The music industry is made up largely of people enamored of music and the instruments they make, but they don't necessarily have great management skills."

As Steinway became more scientific, some stakeholders began to be concerned.Many of the older craftsmen found the new work environment not to their liking, and they left.Equally important, some within the industry began to be concerned that Steinway pianos were losing their personality.Some dealers and their customers even began to question the quality of Steinway's latest pianos.One classical pianist fumed that he had to use a 30-year-old Steinway because he could not find a new one he liked.Another dealer hired a consultant to review the quality of the pianos he had purchased from Steinway.He claimed that the soundboard, a key contributor to a piano's quality, had developed cracks.The consultant reported that this problem "indicated inadequate or improper controls over wood moisture content during various stages of manufacture." Subsequent study indicated that Steinway's new production quotas might have caused workers to pull wood from the conditioning rooms before it was ready to be bent, say, into a piano.

Assume that you are hired as a consultant to help Steinway deal with these latest problems.How could you use a value-driven approach to help this firm address these problems? What would you recommend?

Steinway pianos have long been the premier brand among serious pianists.Franz Liszt called his Steinway "a glorious masterpiece." Gioacchino Rossini, a 19th-century composer, described the Steinway sound as "great as thunder, sweet as the fluting of a nightingale." In short, Steinway's product is the piano of choice for the vast majority of concert artists.

From the beginning, Steinways were a work of art.José Feghali, a classical pianist, illustrated this point when he remarked, "With the best pianos, you can walk into a room with 10 pianos and it's like playing 10 different instruments." The prices of the 5,000 or so pianos that Steinway produces each year range from $10,000 for an upright to $62,000 for a special-order concert grand piano.

In the 1990s, Steinway Sons encountered some problems.John and Robert Birmingham purchased the firm in a $53.5 million leveraged buyout deal.John's previous experience involved making plastic windows for envelopes.Robert's most recent experience was with a mail-order business selling products with bear themes.Robert Birmingham said that they were delighted with the purchase because they viewed Steinway as a "great opportunity" given the firm's "great name and great tradition."

Steinway's craft-driven organization had not fared too well under its previous owner, CBS.The turmoil resulting from frequent management changes had reduced the consistency of Steinway's cherished reputation.Dealers complained that Steinways weren't of the same quality any more-they were often badly tuned and had sloppy finishes.Finally, in 1978, CBS hired a long-time piano industry executive who helped restore much of Steinway's reputation.

Now, a new set of outsiders owned the company.That the owners liked classical music did not assure Steinway's 1,000 employees that they knew how to make classic quality pianos.To make matters worse, the Birmingham brothers were now talking about using their "extensive manufacturing experience" to streamline operations.One commented that the operation was "too reliant on a few craftsmen."

Soon modern manufacturing methods crept into the Steinway operation.A computer control system was introduced to keep track of parts and inventory.Eight million dollars was invested in new equipment to make the quality of small parts, such as piano hammers, more consistent.The loose-leaf binders that specified how pianos were to be built were replaced with engineering drawings.By the late 1980s, Steinway had entered the 20th century.John Birmingham lamented: "The music industry is made up largely of people enamored of music and the instruments they make, but they don't necessarily have great management skills."

As Steinway became more scientific, some stakeholders began to be concerned.Many of the older craftsmen found the new work environment not to their liking, and they left.Equally important, some within the industry began to be concerned that Steinway pianos were losing their personality.Some dealers and their customers even began to question the quality of Steinway's latest pianos.One classical pianist fumed that he had to use a 30-year-old Steinway because he could not find a new one he liked.Another dealer hired a consultant to review the quality of the pianos he had purchased from Steinway.He claimed that the soundboard, a key contributor to a piano's quality, had developed cracks.The consultant reported that this problem "indicated inadequate or improper controls over wood moisture content during various stages of manufacture." Subsequent study indicated that Steinway's new production quotas might have caused workers to pull wood from the conditioning rooms before it was ready to be bent, say, into a piano.

Assume that you are hired as a consultant to help Steinway deal with these latest problems.How could you use a value-driven approach to help this firm address these problems? What would you recommend?

Facts of the case:

The case is about a piano manufacturing company S S.It was popular for the work of art that they produced in their pianos but the company encountered certain problems.This led to the change in the management of the company.The new management had no experience of manufacturing musical instruments.They have changed the manufacturing process by introducing modern manufacturing methods and machines.This was not liked by the old employees of the company and some of the skilled employees quit the company.The company lost its reputation of manufacturing good quality pianos.

Dealing with the problem:

The company has a new management at the top level.The policy making and decisions are taken by these top management people only.They however, fail to understand that manufacturing a piano is different from making plastic windows or mail ordering business selling products.So, first the business structure and its intricacies has to be understood by the top level management.Then, they will have to appreciate the fact that the company has such workers who understand the art of piano making very well and also implement it in making the pianos.

A value-driven approach has to be followed to handle this problem.The management believes that they should manufacture more number of units and sell it for profits but pianos are a work of art and they cannot be made in bulk like any other product.The value of the management and the values of the employees of the company should match with each other.The main aim as well as the basic value of the company is to manufacture and provide the best quality product to the customers of the company.This is possible by creating awareness about the importance of good quality products and implementing quality programmes.The company has to move towards pursuing manufacturing excellence only then will they be able to overcome the given situation and succeed.

The case is about a piano manufacturing company S S.It was popular for the work of art that they produced in their pianos but the company encountered certain problems.This led to the change in the management of the company.The new management had no experience of manufacturing musical instruments.They have changed the manufacturing process by introducing modern manufacturing methods and machines.This was not liked by the old employees of the company and some of the skilled employees quit the company.The company lost its reputation of manufacturing good quality pianos.

Dealing with the problem:

The company has a new management at the top level.The policy making and decisions are taken by these top management people only.They however, fail to understand that manufacturing a piano is different from making plastic windows or mail ordering business selling products.So, first the business structure and its intricacies has to be understood by the top level management.Then, they will have to appreciate the fact that the company has such workers who understand the art of piano making very well and also implement it in making the pianos.

A value-driven approach has to be followed to handle this problem.The management believes that they should manufacture more number of units and sell it for profits but pianos are a work of art and they cannot be made in bulk like any other product.The value of the management and the values of the employees of the company should match with each other.The main aim as well as the basic value of the company is to manufacture and provide the best quality product to the customers of the company.This is possible by creating awareness about the importance of good quality products and implementing quality programmes.The company has to move towards pursuing manufacturing excellence only then will they be able to overcome the given situation and succeed.

2

Why should metrics be regarded as primarily methods of communication? Think about the relationship between a metric, the strategy, and the task being carried out by an operations person.

Metrics are representatives of organizations strategy and priorities related to the process.They provided a narrow down approach and communicate important process performance criteria, which forms the basis by which managers can monitor, control and improve performance of a process by directing efforts and decisions toward the specific objectives.

Operations processes consist of multiple steps and numerous process parameters associated with them.Different functional groups interpret and measure each one in different ways.In addition to this each process parameter doesn't represents company's priorities.

Use of metrics as a primary mode of communication acts as a funnel to communicate the strategic measures important to company, as formulated at the strategic level, to the operational personnel.This helps operation personnel to understand what is expected out of him and thus can direct his efforts on the attributes or parameters important to organizations and customers.Thus it helps in saving time, money and resources.

Operations processes consist of multiple steps and numerous process parameters associated with them.Different functional groups interpret and measure each one in different ways.In addition to this each process parameter doesn't represents company's priorities.

Use of metrics as a primary mode of communication acts as a funnel to communicate the strategic measures important to company, as formulated at the strategic level, to the operational personnel.This helps operation personnel to understand what is expected out of him and thus can direct his efforts on the attributes or parameters important to organizations and customers.Thus it helps in saving time, money and resources.

3

Trail Frames Chassis

Trail Frames Chassis (TFC)of Elkhart, Indiana, is a major manufacturer of chassis for the motor home and van markets.Since it was founded in 1976 by two unemployed truck-manufacturing engineers, TFC has grown into one of the major suppliers in this market.Success in the motor home and van markets is difficult because of the constant rate of change taking place.Increasingly, motor homes and vans are bought by people in their late 40s to 60s.What these people want is a motor home that rides like a car.They are willing to pay for innovations such as ABS (antilock breaking systems), assisted steering, GPS, voice-activated control, and computer-balanced suspension.TFC produces a pusher type of chassis.This is one powered by a diesel engine in which the engine is located in the rear.While expensive to build, this design offers the customer a large number of advantages (no tunnel for the transmission, reduced engine noise, better handling).However, these chassis are used in motor homes that are very expensive ($150,000 and up).TFC builds its chassis for the large manufacturers-companies such as Winnebago, Airstream, and Gulf Stream.In general, these companies place orders for small quantities (5 to 10 in a batch).Many of the units in a batch are customized to a specific customer's requirements.

TFC has become successful because of its ability to develop new lines of designs in a timely fashion.These designs build on TFC's extensive experience with motor home users.They also build on TFC's knowledge of new technological advances and its ability to incorporate these advances into its designs.As a result, TFC has become the technological leader in this market.It is generally recognized that no one in the industry can match TFC's design and marketing knowledge base.

TFC is proud of its ability to design and build highly customized chassis.As John Stickley, its young and aggressive chief operating officer, is proud of pointing out, "Trail Frames has never met a customized chassis it didn't like." Complementing this focus on customization and speed, TFC has developed a culture of doing anything necessary to meet the needs of the customer.Changes are often introduced on the fly with an engineer taking a change down to the assembly line.In many cases, the bills of materials (the recipes for what goes into a given chassis)that were generated initially in engineering do not agree with the components and parts actually put into the chassis.

This approach has served TFC well for a number of years.However, recently sales for TFC have begun to level off.After visiting numerous customers in the field, John Stickley identified what he thought was the reason for this leveling off-the market for high-end, customized motor home chassis had been effectively saturated.There were only just so many customized motor homes that people wanted.Several of the major customers for TFC had strongly hinted that there was another market that TFC could enter that was consistent with its design strengths and its reputation.

Many of TFC's customers had noticed that there was a significant gap between the high-end motor homes that TFC served and the low-end market.The high-end consisted primarily of "pushers," and it began at $150,000; the low-end consisted of "pullers," and these products sold for between $35,000 and $70,000.That is, a motor home manufacturer would take an existing truck body (which consisted of the front end and the cab)and mount on it a motor home body.Obviously, there was a significant gap between the two markets.

One of TFC's major customers, Gulf Stream, approached TFC with an interesting proposal.It wanted TFC to design and build a low-end pusher chassis for this market.This chassis would go into a motor home that would cost between $75,000 and $90,000.In contrast to the current line of products, this chassis would not be customized.Rather, once the chassis was designed, it would not be changed.Production runs would go up from batches of five to batch runs of 100.Critical to success in this market would be cost and conformance to the schedule.If TFC could be the first to produce such a chassis, it would own the market.The financials were very attractive.Theoretically, it seemed easy for TFC to enter this market.All that had to be done was to take an existing chassis and to take out the "costs" by using less-expensive components.While TFC had never built such a chassis, there was no reason why it should not work.The only danger that the people at TFC could identify was that once it entered this market, it would be potentially competing with such firms as Ford, GM, and Toyota (major suppliers of the existing chassis).However, these firms supplied pullers (a chassis with the engine in front)-not pushers, like the proposed TFC product.In light of these issues, John was not sure whether this was the right market for TFc.Compare the order winners, order qualifiers, and order losers for the customized chassis and for the proposed TFC chassis.To what extent are these factors similar?

Trail Frames Chassis (TFC)of Elkhart, Indiana, is a major manufacturer of chassis for the motor home and van markets.Since it was founded in 1976 by two unemployed truck-manufacturing engineers, TFC has grown into one of the major suppliers in this market.Success in the motor home and van markets is difficult because of the constant rate of change taking place.Increasingly, motor homes and vans are bought by people in their late 40s to 60s.What these people want is a motor home that rides like a car.They are willing to pay for innovations such as ABS (antilock breaking systems), assisted steering, GPS, voice-activated control, and computer-balanced suspension.TFC produces a pusher type of chassis.This is one powered by a diesel engine in which the engine is located in the rear.While expensive to build, this design offers the customer a large number of advantages (no tunnel for the transmission, reduced engine noise, better handling).However, these chassis are used in motor homes that are very expensive ($150,000 and up).TFC builds its chassis for the large manufacturers-companies such as Winnebago, Airstream, and Gulf Stream.In general, these companies place orders for small quantities (5 to 10 in a batch).Many of the units in a batch are customized to a specific customer's requirements.

TFC has become successful because of its ability to develop new lines of designs in a timely fashion.These designs build on TFC's extensive experience with motor home users.They also build on TFC's knowledge of new technological advances and its ability to incorporate these advances into its designs.As a result, TFC has become the technological leader in this market.It is generally recognized that no one in the industry can match TFC's design and marketing knowledge base.

TFC is proud of its ability to design and build highly customized chassis.As John Stickley, its young and aggressive chief operating officer, is proud of pointing out, "Trail Frames has never met a customized chassis it didn't like." Complementing this focus on customization and speed, TFC has developed a culture of doing anything necessary to meet the needs of the customer.Changes are often introduced on the fly with an engineer taking a change down to the assembly line.In many cases, the bills of materials (the recipes for what goes into a given chassis)that were generated initially in engineering do not agree with the components and parts actually put into the chassis.

This approach has served TFC well for a number of years.However, recently sales for TFC have begun to level off.After visiting numerous customers in the field, John Stickley identified what he thought was the reason for this leveling off-the market for high-end, customized motor home chassis had been effectively saturated.There were only just so many customized motor homes that people wanted.Several of the major customers for TFC had strongly hinted that there was another market that TFC could enter that was consistent with its design strengths and its reputation.

Many of TFC's customers had noticed that there was a significant gap between the high-end motor homes that TFC served and the low-end market.The high-end consisted primarily of "pushers," and it began at $150,000; the low-end consisted of "pullers," and these products sold for between $35,000 and $70,000.That is, a motor home manufacturer would take an existing truck body (which consisted of the front end and the cab)and mount on it a motor home body.Obviously, there was a significant gap between the two markets.

One of TFC's major customers, Gulf Stream, approached TFC with an interesting proposal.It wanted TFC to design and build a low-end pusher chassis for this market.This chassis would go into a motor home that would cost between $75,000 and $90,000.In contrast to the current line of products, this chassis would not be customized.Rather, once the chassis was designed, it would not be changed.Production runs would go up from batches of five to batch runs of 100.Critical to success in this market would be cost and conformance to the schedule.If TFC could be the first to produce such a chassis, it would own the market.The financials were very attractive.Theoretically, it seemed easy for TFC to enter this market.All that had to be done was to take an existing chassis and to take out the "costs" by using less-expensive components.While TFC had never built such a chassis, there was no reason why it should not work.The only danger that the people at TFC could identify was that once it entered this market, it would be potentially competing with such firms as Ford, GM, and Toyota (major suppliers of the existing chassis).However, these firms supplied pullers (a chassis with the engine in front)-not pushers, like the proposed TFC product.In light of these issues, John was not sure whether this was the right market for TFc.Compare the order winners, order qualifiers, and order losers for the customized chassis and for the proposed TFC chassis.To what extent are these factors similar?

Order winner: Order winners have the competitive advantages that cause a firm's customers to choose the firm's product or service over its competitors.

Order qualifiers: These are those competitive advantages that a firm must exhibit in order to be a viable competitor in the marketplace.

Order losers: Order losers are simply not meeting the order winners.

Order winners for customized chassis are:

Innovation: TFC produces a pusher type of chassis powered by a diesel engine in which the engine is located in the rear.They also build on TFC's knowledge of new technologies advances and its ability to incorporate these advances into its design.

Customization: TFC was very creative in designing and building highly customized chassis.

Fast production: TFC develops new line of designs in timely fashion.Their design and market knowledge base was the best in industry.

Order winner for proposed TFC chassis are:

Innovation: TFC could be the first to produce low-end pusher chassis.They have a first mover advantage.They can easily increase their sales and production.

Low-end pusher chassis: TFC was asked to design and build a low-end pusher chassis; this chassis would not be customized.

Order qualifiers for customized chassis are:

Quality of product: TFC was proud of its ability to design and build highly customized chassis.

Customization of product: TFC builds its product for large manufacturers- companies such as Winnebago, Airstream and Gulf Stream.These companies place orders for small quantity (5 to 10 in a batch).These units in a batch are customized to a specific customer's requirement.

Order qualifiers for proposed chassis are:

Competitive Price: The low-end pusher chassis would go into a motor home that would cost between $75000 and $90000.

Standardization of product: The chassis would not be customized.Standardization of products will be followed, once the chassis was designed, it would not be changed.

Increase in production: production run of low-end chassis would go up from batches of five to batches run of 100.

Order losers for customized chassis are:

Market saturation leads to stagnant business and decline in future sales.Inability to accurately predict future market demand was the main reason for decline in sales.

Order losers for proposed chassis are:

TFC would be the first to produce low-end pusher chassis.Inability to understand and adjust to new production strategy may result in error in the work place which will result in poor quality products.They will have to compete with firms such as Ford, GM, and Toyota to remain in the market.Ford, GM, and Toyota supplied pullers not pushers, like the proposed Trail Frames Chassis product.

Order winners

TFC constantly focus on innovation and its ability to develop new lines of design in a timely manner and delivering the product in short time.Earlier they were manufacturing for high-end pusher chassis and know they are asked to manufactures low-end pusher chassis.

Order qualifiers

TFC maintain the quality of the product and quality of service offered.Earlier the focus of TFC was towards customization of the product but the Gulf Stream proposal was not interested in customization.Rather once, the chassis was design it would not be changed.

Order losers

Inability to accurately predict future market demand was the main problem for Trail Frames Chassis.Eventually it may result in poor sales in future.

Order qualifiers: These are those competitive advantages that a firm must exhibit in order to be a viable competitor in the marketplace.

Order losers: Order losers are simply not meeting the order winners.

Order winners for customized chassis are:

Innovation: TFC produces a pusher type of chassis powered by a diesel engine in which the engine is located in the rear.They also build on TFC's knowledge of new technologies advances and its ability to incorporate these advances into its design.

Customization: TFC was very creative in designing and building highly customized chassis.

Fast production: TFC develops new line of designs in timely fashion.Their design and market knowledge base was the best in industry.

Order winner for proposed TFC chassis are:

Innovation: TFC could be the first to produce low-end pusher chassis.They have a first mover advantage.They can easily increase their sales and production.

Low-end pusher chassis: TFC was asked to design and build a low-end pusher chassis; this chassis would not be customized.

Order qualifiers for customized chassis are:

Quality of product: TFC was proud of its ability to design and build highly customized chassis.

Customization of product: TFC builds its product for large manufacturers- companies such as Winnebago, Airstream and Gulf Stream.These companies place orders for small quantity (5 to 10 in a batch).These units in a batch are customized to a specific customer's requirement.

Order qualifiers for proposed chassis are:

Competitive Price: The low-end pusher chassis would go into a motor home that would cost between $75000 and $90000.

Standardization of product: The chassis would not be customized.Standardization of products will be followed, once the chassis was designed, it would not be changed.

Increase in production: production run of low-end chassis would go up from batches of five to batches run of 100.

Order losers for customized chassis are:

Market saturation leads to stagnant business and decline in future sales.Inability to accurately predict future market demand was the main reason for decline in sales.

Order losers for proposed chassis are:

TFC would be the first to produce low-end pusher chassis.Inability to understand and adjust to new production strategy may result in error in the work place which will result in poor quality products.They will have to compete with firms such as Ford, GM, and Toyota to remain in the market.Ford, GM, and Toyota supplied pullers not pushers, like the proposed Trail Frames Chassis product.

Order winners

TFC constantly focus on innovation and its ability to develop new lines of design in a timely manner and delivering the product in short time.Earlier they were manufacturing for high-end pusher chassis and know they are asked to manufactures low-end pusher chassis.

Order qualifiers

TFC maintain the quality of the product and quality of service offered.Earlier the focus of TFC was towards customization of the product but the Gulf Stream proposal was not interested in customization.Rather once, the chassis was design it would not be changed.

Order losers

Inability to accurately predict future market demand was the main problem for Trail Frames Chassis.Eventually it may result in poor sales in future.

4

A metric consists of three elements: the measure, the standard (what is expected), and the reward.Why are all three elements critical? What happens to the effectiveness of a metric when one of these three elements is missing?

Unlock Deck

Unlock for access to all 23 flashcards in this deck.

Unlock Deck

k this deck

5

Why should the firm never outsource its core capabilities? What happens if the firm is approached by a supplier who is willing to supply goods and services based on these core capabilities at a significantly lower price? What should the firm do?

Unlock Deck

Unlock for access to all 23 flashcards in this deck.

Unlock Deck

k this deck

6

What is the impact of sustainability on the business model? How does it affect issues such as the Order Winners, Order Losers, and Order Qualifiers? How does it affect the identification of the critical customer? When addressing this question, look up such products as Chrome or Timbuk2 for bags or Teva or Mio or Timberlane for shoes.

Unlock Deck

Unlock for access to all 23 flashcards in this deck.

Unlock Deck

k this deck

7

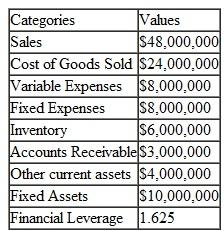

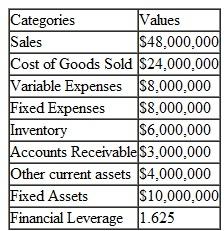

Given the information above:

Given the information above:?a.?What is the Net profit margin for this firm?

Unlock Deck

Unlock for access to all 23 flashcards in this deck.

Unlock Deck

k this deck

8

Why is there a need for the four dimensions of the balanced scorecard?

Unlock Deck

Unlock for access to all 23 flashcards in this deck.

Unlock Deck

k this deck

9

Otis Toy Trains Explores the Supply Chain

Otis Toy Trains of Minneapolis, Minnesota, was a landmark company in the toy business.Since the 1900s, it had been responsible for building electrical and steam-driven toy trains.Since the 1950s, Otis trains had developed a major presence on children's television shows.Every person (especially boys)knew about Otis toy trains and nearly everyone wanted one.For many kids growing up in the 1960s to the 1980s, waking up on Christmas day and finding an Otis toy train set under the tree was a dream come true.However, the 1990s had not been good to Otis Toy Trains.The preferences of many children had changed.Instead of toys, what many children wanted was a game playing system (like Sony's PS2 or Microsoft Xbox or Nintindo's GameBoy Advanced).After a lot of investigation and assessment, the management at Otis had decided to reorient the product and the market.Consequently, it decided to target the adult male customer in the 30 to 50 year age bracket.This market was selected for several reasons.First, they had grown up with Otis toy trains and, as a result, Otis had excellent brand recognition among these buyers.Second, since Otis had decided to maintain the bulk of its production facilities in the areas around Minneapolis (the major production facility was located in Rochester, Minnesota), it needed a buyer who was willing to pay the premium now demanded by Otis Toy Trains for its products.Adult males in the 30 to 50 year age bracket typically had the income that supported luxury buys such as the Otis toy trains.Finally, the new target market was attractive because they tended to buy more than one system and they tended to buy a large number of accessories with their toy train purchases.

To sell to this new market, Otis introduced in 1995 the Otis Premium Trains of the Past series.This was a line of highly detailed, highly accurate trains drawn from critical points in North American history.The first launch consisted of the De Witt Clinton Rocket (the first train operated in the United States), the Abraham Lincoln train (a train model based on the train coaches that were used to transport the body of the recently assassinated President Lincoln from Washington, DC, to Springfield, IL, for final burial), the Zephyr (the famous streamlined train that ran between Chicago and Denver during the 1930s), and the Orange Blossom Special.Launched in limited numbers, this first series was an unqualified success.Subsequent launches were almost as successful.Over this time, the designers at Otis Toy Trains developed and refined the skill of identifying attractive train series and of designing products that were detailed, attractive, accurate, and highly evocative of past times.

By 2006, however, Otis Toy Trains found itself faced by the challenge of dealing with increasing labor costs.It was during this time period that the Joyous Luck Prosperity Toy Company (JLPTC)of China approached the management of the Otis Toy Train Company with a proposal that had already secured the support of Otis corporate accountants.They proposed to work closely with the designers of the Otis Toy Train Company with the goal of taking over the bulk of production of the Otis Premium Trains of the Past series.What JLPTC offered Otis was a landed price per unit that was between 40 to 60 percent lower than current manufacturing costs.This was a price that was too good to pass up.

Assume that Otis decided to accept this proposal.Identify and discuss the most appropriate relationship that you would recommend for Otis and JLPTC? What risks are present in this proposal? How could Otis protect itself from these risks?

Otis Toy Trains of Minneapolis, Minnesota, was a landmark company in the toy business.Since the 1900s, it had been responsible for building electrical and steam-driven toy trains.Since the 1950s, Otis trains had developed a major presence on children's television shows.Every person (especially boys)knew about Otis toy trains and nearly everyone wanted one.For many kids growing up in the 1960s to the 1980s, waking up on Christmas day and finding an Otis toy train set under the tree was a dream come true.However, the 1990s had not been good to Otis Toy Trains.The preferences of many children had changed.Instead of toys, what many children wanted was a game playing system (like Sony's PS2 or Microsoft Xbox or Nintindo's GameBoy Advanced).After a lot of investigation and assessment, the management at Otis had decided to reorient the product and the market.Consequently, it decided to target the adult male customer in the 30 to 50 year age bracket.This market was selected for several reasons.First, they had grown up with Otis toy trains and, as a result, Otis had excellent brand recognition among these buyers.Second, since Otis had decided to maintain the bulk of its production facilities in the areas around Minneapolis (the major production facility was located in Rochester, Minnesota), it needed a buyer who was willing to pay the premium now demanded by Otis Toy Trains for its products.Adult males in the 30 to 50 year age bracket typically had the income that supported luxury buys such as the Otis toy trains.Finally, the new target market was attractive because they tended to buy more than one system and they tended to buy a large number of accessories with their toy train purchases.

To sell to this new market, Otis introduced in 1995 the Otis Premium Trains of the Past series.This was a line of highly detailed, highly accurate trains drawn from critical points in North American history.The first launch consisted of the De Witt Clinton Rocket (the first train operated in the United States), the Abraham Lincoln train (a train model based on the train coaches that were used to transport the body of the recently assassinated President Lincoln from Washington, DC, to Springfield, IL, for final burial), the Zephyr (the famous streamlined train that ran between Chicago and Denver during the 1930s), and the Orange Blossom Special.Launched in limited numbers, this first series was an unqualified success.Subsequent launches were almost as successful.Over this time, the designers at Otis Toy Trains developed and refined the skill of identifying attractive train series and of designing products that were detailed, attractive, accurate, and highly evocative of past times.

By 2006, however, Otis Toy Trains found itself faced by the challenge of dealing with increasing labor costs.It was during this time period that the Joyous Luck Prosperity Toy Company (JLPTC)of China approached the management of the Otis Toy Train Company with a proposal that had already secured the support of Otis corporate accountants.They proposed to work closely with the designers of the Otis Toy Train Company with the goal of taking over the bulk of production of the Otis Premium Trains of the Past series.What JLPTC offered Otis was a landed price per unit that was between 40 to 60 percent lower than current manufacturing costs.This was a price that was too good to pass up.

Assume that Otis decided to accept this proposal.Identify and discuss the most appropriate relationship that you would recommend for Otis and JLPTC? What risks are present in this proposal? How could Otis protect itself from these risks?

Unlock Deck

Unlock for access to all 23 flashcards in this deck.

Unlock Deck

k this deck

10

As North American firms increasingly turn to product innovation, the management and protection of intellectual property becomes an important issue.Discuss how intellectual property considerations can affect such areas in supply chain strategy as:

a.Supplier relationships.

b.Supplier contracts.

c.Supplier location.

d.Attractiveness of vertical integration.

a.Supplier relationships.

b.Supplier contracts.

c.Supplier location.

d.Attractiveness of vertical integration.

Unlock Deck

Unlock for access to all 23 flashcards in this deck.

Unlock Deck

k this deck

11

Trail Frames Chassis

Trail Frames Chassis (TFC)of Elkhart, Indiana, is a major manufacturer of chassis for the motor home and van markets.Since it was founded in 1976 by two unemployed truck-manufacturing engineers, TFC has grown into one of the major suppliers in this market.Success in the motor home and van markets is difficult because of the constant rate of change taking place.Increasingly, motor homes and vans are bought by people in their late 40s to 60s.What these people want is a motor home that rides like a car.They are willing to pay for innovations such as ABS (antilock breaking systems), assisted steering, GPS, voice-activated control, and computer-balanced suspension.TFC produces a pusher type of chassis.This is one powered by a diesel engine in which the engine is located in the rear.While expensive to build, this design offers the customer a large number of advantages (no tunnel for the transmission, reduced engine noise, better handling).However, these chassis are used in motor homes that are very expensive ($150,000 and up).TFC builds its chassis for the large manufacturers-companies such as Winnebago, Airstream, and Gulf Stream.In general, these companies place orders for small quantities (5 to 10 in a batch).Many of the units in a batch are customized to a specific customer's requirements.

TFC has become successful because of its ability to develop new lines of designs in a timely fashion.These designs build on TFC's extensive experience with motor home users.They also build on TFC's knowledge of new technological advances and its ability to incorporate these advances into its designs.As a result, TFC has become the technological leader in this market.It is generally recognized that no one in the industry can match TFC's design and marketing knowledge base.

TFC is proud of its ability to design and build highly customized chassis.As John Stickley, its young and aggressive chief operating officer, is proud of pointing out, "Trail Frames has never met a customized chassis it didn't like." Complementing this focus on customization and speed, TFC has developed a culture of doing anything necessary to meet the needs of the customer.Changes are often introduced on the fly with an engineer taking a change down to the assembly line.In many cases, the bills of materials (the recipes for what goes into a given chassis)that were generated initially in engineering do not agree with the components and parts actually put into the chassis.

This approach has served TFC well for a number of years.However, recently sales for TFC have begun to level off.After visiting numerous customers in the field, John Stickley identified what he thought was the reason for this leveling off-the market for high-end, customized motor home chassis had been effectively saturated.There were only just so many customized motor homes that people wanted.Several of the major customers for TFC had strongly hinted that there was another market that TFC could enter that was consistent with its design strengths and its reputation.

Many of TFC's customers had noticed that there was a significant gap between the high-end motor homes that TFC served and the low-end market.The high-end consisted primarily of "pushers," and it began at $150,000; the low-end consisted of "pullers," and these products sold for between $35,000 and $70,000.That is, a motor home manufacturer would take an existing truck body (which consisted of the front end and the cab)and mount on it a motor home body.Obviously, there was a significant gap between the two markets.

One of TFC's major customers, Gulf Stream, approached TFC with an interesting proposal.It wanted TFC to design and build a low-end pusher chassis for this market.This chassis would go into a motor home that would cost between $75,000 and $90,000.In contrast to the current line of products, this chassis would not be customized.Rather, once the chassis was designed, it would not be changed.Production runs would go up from batches of five to batch runs of 100.Critical to success in this market would be cost and conformance to the schedule.If TFC could be the first to produce such a chassis, it would own the market.The financials were very attractive.Theoretically, it seemed easy for TFC to enter this market.All that had to be done was to take an existing chassis and to take out the "costs" by using less-expensive components.While TFC had never built such a chassis, there was no reason why it should not work.The only danger that the people at TFC could identify was that once it entered this market, it would be potentially competing with such firms as Ford, GM, and Toyota (major suppliers of the existing chassis).However, these firms supplied pullers (a chassis with the engine in front)-not pushers, like the proposed TFC product.In light of these issues, John was not sure whether this was the right market for TFc.What type of strategic consistency would you expect to find in TFC for its existing customized chassis? Would this be the same type of consistency that you would find with the proposed chassis?

Trail Frames Chassis (TFC)of Elkhart, Indiana, is a major manufacturer of chassis for the motor home and van markets.Since it was founded in 1976 by two unemployed truck-manufacturing engineers, TFC has grown into one of the major suppliers in this market.Success in the motor home and van markets is difficult because of the constant rate of change taking place.Increasingly, motor homes and vans are bought by people in their late 40s to 60s.What these people want is a motor home that rides like a car.They are willing to pay for innovations such as ABS (antilock breaking systems), assisted steering, GPS, voice-activated control, and computer-balanced suspension.TFC produces a pusher type of chassis.This is one powered by a diesel engine in which the engine is located in the rear.While expensive to build, this design offers the customer a large number of advantages (no tunnel for the transmission, reduced engine noise, better handling).However, these chassis are used in motor homes that are very expensive ($150,000 and up).TFC builds its chassis for the large manufacturers-companies such as Winnebago, Airstream, and Gulf Stream.In general, these companies place orders for small quantities (5 to 10 in a batch).Many of the units in a batch are customized to a specific customer's requirements.

TFC has become successful because of its ability to develop new lines of designs in a timely fashion.These designs build on TFC's extensive experience with motor home users.They also build on TFC's knowledge of new technological advances and its ability to incorporate these advances into its designs.As a result, TFC has become the technological leader in this market.It is generally recognized that no one in the industry can match TFC's design and marketing knowledge base.

TFC is proud of its ability to design and build highly customized chassis.As John Stickley, its young and aggressive chief operating officer, is proud of pointing out, "Trail Frames has never met a customized chassis it didn't like." Complementing this focus on customization and speed, TFC has developed a culture of doing anything necessary to meet the needs of the customer.Changes are often introduced on the fly with an engineer taking a change down to the assembly line.In many cases, the bills of materials (the recipes for what goes into a given chassis)that were generated initially in engineering do not agree with the components and parts actually put into the chassis.

This approach has served TFC well for a number of years.However, recently sales for TFC have begun to level off.After visiting numerous customers in the field, John Stickley identified what he thought was the reason for this leveling off-the market for high-end, customized motor home chassis had been effectively saturated.There were only just so many customized motor homes that people wanted.Several of the major customers for TFC had strongly hinted that there was another market that TFC could enter that was consistent with its design strengths and its reputation.

Many of TFC's customers had noticed that there was a significant gap between the high-end motor homes that TFC served and the low-end market.The high-end consisted primarily of "pushers," and it began at $150,000; the low-end consisted of "pullers," and these products sold for between $35,000 and $70,000.That is, a motor home manufacturer would take an existing truck body (which consisted of the front end and the cab)and mount on it a motor home body.Obviously, there was a significant gap between the two markets.

One of TFC's major customers, Gulf Stream, approached TFC with an interesting proposal.It wanted TFC to design and build a low-end pusher chassis for this market.This chassis would go into a motor home that would cost between $75,000 and $90,000.In contrast to the current line of products, this chassis would not be customized.Rather, once the chassis was designed, it would not be changed.Production runs would go up from batches of five to batch runs of 100.Critical to success in this market would be cost and conformance to the schedule.If TFC could be the first to produce such a chassis, it would own the market.The financials were very attractive.Theoretically, it seemed easy for TFC to enter this market.All that had to be done was to take an existing chassis and to take out the "costs" by using less-expensive components.While TFC had never built such a chassis, there was no reason why it should not work.The only danger that the people at TFC could identify was that once it entered this market, it would be potentially competing with such firms as Ford, GM, and Toyota (major suppliers of the existing chassis).However, these firms supplied pullers (a chassis with the engine in front)-not pushers, like the proposed TFC product.In light of these issues, John was not sure whether this was the right market for TFc.What type of strategic consistency would you expect to find in TFC for its existing customized chassis? Would this be the same type of consistency that you would find with the proposed chassis?

Unlock Deck

Unlock for access to all 23 flashcards in this deck.

Unlock Deck

k this deck

12

Elm Furniture Company, a medium-sized, publicly traded manufacturer of wood-based office and home furniture systems, has agreed that its major goal should be to "Become recognized as a value and social leader in the wood furniture industry." Consistent with this macro goal, Elm Furniture had identified the following specific objectives:

• Become recognized as a leader in the use and application of environmentally responsible practices and systems.

• Achieve sales growth averaging 5 percent more than that of the industry average.

• Keep stock price stable relative to that of the industry average.

• Reduce cost and waste at all levels of the fi rm.

• Be recognized as a design leader.

Using these goals and the balanced scorecard approach, what would the corresponding goals and metrics be for the following?

a.Operations management/manufacturing.

b.Product engineering and design.

c.Sales and marketing.

d.Purchasing/supply chain management.

• Become recognized as a leader in the use and application of environmentally responsible practices and systems.

• Achieve sales growth averaging 5 percent more than that of the industry average.

• Keep stock price stable relative to that of the industry average.

• Reduce cost and waste at all levels of the fi rm.

• Be recognized as a design leader.

Using these goals and the balanced scorecard approach, what would the corresponding goals and metrics be for the following?

a.Operations management/manufacturing.

b.Product engineering and design.

c.Sales and marketing.

d.Purchasing/supply chain management.

Unlock Deck

Unlock for access to all 23 flashcards in this deck.

Unlock Deck

k this deck

13

Apply the corporate/SBU/functional planning hierarchy introduced in this chapter to your university/college or business.What would be the equivalent to corporate planning? SBU planning? Functional Planning?

Unlock Deck

Unlock for access to all 23 flashcards in this deck.

Unlock Deck

k this deck

14

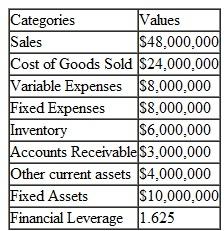

The managers of the firm described in problem 1 claim that the Return on Net Worth for the firm is

58.70? If this is the case, then what financial leverage is required to achieve this return?

(In Reference Problem 1)

58.70? If this is the case, then what financial leverage is required to achieve this return?

(In Reference Problem 1)

Unlock Deck

Unlock for access to all 23 flashcards in this deck.

Unlock Deck

k this deck

15

Trail Frames Chassis

Trail Frames Chassis (TFC)of Elkhart, Indiana, is a major manufacturer of chassis for the motor home and van markets.Since it was founded in 1976 by two unemployed truck-manufacturing engineers, TFC has grown into one of the major suppliers in this market.Success in the motor home and van markets is difficult because of the constant rate of change taking place.Increasingly, motor homes and vans are bought by people in their late 40s to 60s.What these people want is a motor home that rides like a car.They are willing to pay for innovations such as ABS (antilock breaking systems), assisted steering, GPS, voice-activated control, and computer-balanced suspension.TFC produces a pusher type of chassis.This is one powered by a diesel engine in which the engine is located in the rear.While expensive to build, this design offers the customer a large number of advantages (no tunnel for the transmission, reduced engine noise, better handling).However, these chassis are used in motor homes that are very expensive ($150,000 and up).TFC builds its chassis for the large manufacturers-companies such as Winnebago, Airstream, and Gulf Stream.In general, these companies place orders for small quantities (5 to 10 in a batch).Many of the units in a batch are customized to a specific customer's requirements.

TFC has become successful because of its ability to develop new lines of designs in a timely fashion.These designs build on TFC's extensive experience with motor home users.They also build on TFC's knowledge of new technological advances and its ability to incorporate these advances into its designs.As a result, TFC has become the technological leader in this market.It is generally recognized that no one in the industry can match TFC's design and marketing knowledge base.

TFC is proud of its ability to design and build highly customized chassis.As John Stickley, its young and aggressive chief operating officer, is proud of pointing out, "Trail Frames has never met a customized chassis it didn't like." Complementing this focus on customization and speed, TFC has developed a culture of doing anything necessary to meet the needs of the customer.Changes are often introduced on the fly with an engineer taking a change down to the assembly line.In many cases, the bills of materials (the recipes for what goes into a given chassis)that were generated initially in engineering do not agree with the components and parts actually put into the chassis.

This approach has served TFC well for a number of years.However, recently sales for TFC have begun to level off.After visiting numerous customers in the field, John Stickley identified what he thought was the reason for this leveling off-the market for high-end, customized motor home chassis had been effectively saturated.There were only just so many customized motor homes that people wanted.Several of the major customers for TFC had strongly hinted that there was another market that TFC could enter that was consistent with its design strengths and its reputation.

Many of TFC's customers had noticed that there was a significant gap between the high-end motor homes that TFC served and the low-end market.The high-end consisted primarily of "pushers," and it began at $150,000; the low-end consisted of "pullers," and these products sold for between $35,000 and $70,000.That is, a motor home manufacturer would take an existing truck body (which consisted of the front end and the cab)and mount on it a motor home body.Obviously, there was a significant gap between the two markets.

One of TFC's major customers, Gulf Stream, approached TFC with an interesting proposal.It wanted TFC to design and build a low-end pusher chassis for this market.This chassis would go into a motor home that would cost between $75,000 and $90,000.In contrast to the current line of products, this chassis would not be customized.Rather, once the chassis was designed, it would not be changed.Production runs would go up from batches of five to batch runs of 100.Critical to success in this market would be cost and conformance to the schedule.If TFC could be the first to produce such a chassis, it would own the market.The financials were very attractive.Theoretically, it seemed easy for TFC to enter this market.All that had to be done was to take an existing chassis and to take out the "costs" by using less-expensive components.While TFC had never built such a chassis, there was no reason why it should not work.The only danger that the people at TFC could identify was that once it entered this market, it would be potentially competing with such firms as Ford, GM, and Toyota (major suppliers of the existing chassis).However, these firms supplied pullers (a chassis with the engine in front)-not pushers, like the proposed TFC product.In light of these issues, John was not sure whether this was the right market for TFc.Evaluate the proposal for this new line of chassis.Is this a business that TFC should get into? If yes, why? If no, why not?

Trail Frames Chassis (TFC)of Elkhart, Indiana, is a major manufacturer of chassis for the motor home and van markets.Since it was founded in 1976 by two unemployed truck-manufacturing engineers, TFC has grown into one of the major suppliers in this market.Success in the motor home and van markets is difficult because of the constant rate of change taking place.Increasingly, motor homes and vans are bought by people in their late 40s to 60s.What these people want is a motor home that rides like a car.They are willing to pay for innovations such as ABS (antilock breaking systems), assisted steering, GPS, voice-activated control, and computer-balanced suspension.TFC produces a pusher type of chassis.This is one powered by a diesel engine in which the engine is located in the rear.While expensive to build, this design offers the customer a large number of advantages (no tunnel for the transmission, reduced engine noise, better handling).However, these chassis are used in motor homes that are very expensive ($150,000 and up).TFC builds its chassis for the large manufacturers-companies such as Winnebago, Airstream, and Gulf Stream.In general, these companies place orders for small quantities (5 to 10 in a batch).Many of the units in a batch are customized to a specific customer's requirements.

TFC has become successful because of its ability to develop new lines of designs in a timely fashion.These designs build on TFC's extensive experience with motor home users.They also build on TFC's knowledge of new technological advances and its ability to incorporate these advances into its designs.As a result, TFC has become the technological leader in this market.It is generally recognized that no one in the industry can match TFC's design and marketing knowledge base.

TFC is proud of its ability to design and build highly customized chassis.As John Stickley, its young and aggressive chief operating officer, is proud of pointing out, "Trail Frames has never met a customized chassis it didn't like." Complementing this focus on customization and speed, TFC has developed a culture of doing anything necessary to meet the needs of the customer.Changes are often introduced on the fly with an engineer taking a change down to the assembly line.In many cases, the bills of materials (the recipes for what goes into a given chassis)that were generated initially in engineering do not agree with the components and parts actually put into the chassis.

This approach has served TFC well for a number of years.However, recently sales for TFC have begun to level off.After visiting numerous customers in the field, John Stickley identified what he thought was the reason for this leveling off-the market for high-end, customized motor home chassis had been effectively saturated.There were only just so many customized motor homes that people wanted.Several of the major customers for TFC had strongly hinted that there was another market that TFC could enter that was consistent with its design strengths and its reputation.

Many of TFC's customers had noticed that there was a significant gap between the high-end motor homes that TFC served and the low-end market.The high-end consisted primarily of "pushers," and it began at $150,000; the low-end consisted of "pullers," and these products sold for between $35,000 and $70,000.That is, a motor home manufacturer would take an existing truck body (which consisted of the front end and the cab)and mount on it a motor home body.Obviously, there was a significant gap between the two markets.

One of TFC's major customers, Gulf Stream, approached TFC with an interesting proposal.It wanted TFC to design and build a low-end pusher chassis for this market.This chassis would go into a motor home that would cost between $75,000 and $90,000.In contrast to the current line of products, this chassis would not be customized.Rather, once the chassis was designed, it would not be changed.Production runs would go up from batches of five to batch runs of 100.Critical to success in this market would be cost and conformance to the schedule.If TFC could be the first to produce such a chassis, it would own the market.The financials were very attractive.Theoretically, it seemed easy for TFC to enter this market.All that had to be done was to take an existing chassis and to take out the "costs" by using less-expensive components.While TFC had never built such a chassis, there was no reason why it should not work.The only danger that the people at TFC could identify was that once it entered this market, it would be potentially competing with such firms as Ford, GM, and Toyota (major suppliers of the existing chassis).However, these firms supplied pullers (a chassis with the engine in front)-not pushers, like the proposed TFC product.In light of these issues, John was not sure whether this was the right market for TFc.Evaluate the proposal for this new line of chassis.Is this a business that TFC should get into? If yes, why? If no, why not?

Unlock Deck

Unlock for access to all 23 flashcards in this deck.

Unlock Deck

k this deck

16

How would you define capabilities within a school or business?

Unlock Deck

Unlock for access to all 23 flashcards in this deck.

Unlock Deck

k this deck

17

Trail Frames Chassis

Trail Frames Chassis (TFC)of Elkhart, Indiana, is a major manufacturer of chassis for the motor home and van markets.Since it was founded in 1976 by two unemployed truck-manufacturing engineers, TFC has grown into one of the major suppliers in this market.Success in the motor home and van markets is difficult because of the constant rate of change taking place.Increasingly, motor homes and vans are bought by people in their late 40s to 60s.What these people want is a motor home that rides like a car.They are willing to pay for innovations such as ABS (antilock breaking systems), assisted steering, GPS, voice-activated control, and computer-balanced suspension.TFC produces a pusher type of chassis.This is one powered by a diesel engine in which the engine is located in the rear.While expensive to build, this design offers the customer a large number of advantages (no tunnel for the transmission, reduced engine noise, better handling).However, these chassis are used in motor homes that are very expensive ($150,000 and up).TFC builds its chassis for the large manufacturers-companies such as Winnebago, Airstream, and Gulf Stream.In general, these companies place orders for small quantities (5 to 10 in a batch).Many of the units in a batch are customized to a specific customer's requirements.

TFC has become successful because of its ability to develop new lines of designs in a timely fashion.These designs build on TFC's extensive experience with motor home users.They also build on TFC's knowledge of new technological advances and its ability to incorporate these advances into its designs.As a result, TFC has become the technological leader in this market.It is generally recognized that no one in the industry can match TFC's design and marketing knowledge base.

TFC is proud of its ability to design and build highly customized chassis.As John Stickley, its young and aggressive chief operating officer, is proud of pointing out, "Trail Frames has never met a customized chassis it didn't like." Complementing this focus on customization and speed, TFC has developed a culture of doing anything necessary to meet the needs of the customer.Changes are often introduced on the fly with an engineer taking a change down to the assembly line.In many cases, the bills of materials (the recipes for what goes into a given chassis)that were generated initially in engineering do not agree with the components and parts actually put into the chassis.

This approach has served TFC well for a number of years.However, recently sales for TFC have begun to level off.After visiting numerous customers in the field, John Stickley identified what he thought was the reason for this leveling off-the market for high-end, customized motor home chassis had been effectively saturated.There were only just so many customized motor homes that people wanted.Several of the major customers for TFC had strongly hinted that there was another market that TFC could enter that was consistent with its design strengths and its reputation.

Many of TFC's customers had noticed that there was a significant gap between the high-end motor homes that TFC served and the low-end market.The high-end consisted primarily of "pushers," and it began at $150,000; the low-end consisted of "pullers," and these products sold for between $35,000 and $70,000.That is, a motor home manufacturer would take an existing truck body (which consisted of the front end and the cab)and mount on it a motor home body.Obviously, there was a significant gap between the two markets.

One of TFC's major customers, Gulf Stream, approached TFC with an interesting proposal.It wanted TFC to design and build a low-end pusher chassis for this market.This chassis would go into a motor home that would cost between $75,000 and $90,000.In contrast to the current line of products, this chassis would not be customized.Rather, once the chassis was designed, it would not be changed.Production runs would go up from batches of five to batch runs of 100.Critical to success in this market would be cost and conformance to the schedule.If TFC could be the first to produce such a chassis, it would own the market.The financials were very attractive.Theoretically, it seemed easy for TFC to enter this market.All that had to be done was to take an existing chassis and to take out the "costs" by using less-expensive components.While TFC had never built such a chassis, there was no reason why it should not work.The only danger that the people at TFC could identify was that once it entered this market, it would be potentially competing with such firms as Ford, GM, and Toyota (major suppliers of the existing chassis).However, these firms supplied pullers (a chassis with the engine in front)-not pushers, like the proposed TFC product.In light of these issues, John was not sure whether this was the right market for TFc.What would you recommend to John Stickley that TFC should do to increase its sales and to stimulate demand?

Trail Frames Chassis (TFC)of Elkhart, Indiana, is a major manufacturer of chassis for the motor home and van markets.Since it was founded in 1976 by two unemployed truck-manufacturing engineers, TFC has grown into one of the major suppliers in this market.Success in the motor home and van markets is difficult because of the constant rate of change taking place.Increasingly, motor homes and vans are bought by people in their late 40s to 60s.What these people want is a motor home that rides like a car.They are willing to pay for innovations such as ABS (antilock breaking systems), assisted steering, GPS, voice-activated control, and computer-balanced suspension.TFC produces a pusher type of chassis.This is one powered by a diesel engine in which the engine is located in the rear.While expensive to build, this design offers the customer a large number of advantages (no tunnel for the transmission, reduced engine noise, better handling).However, these chassis are used in motor homes that are very expensive ($150,000 and up).TFC builds its chassis for the large manufacturers-companies such as Winnebago, Airstream, and Gulf Stream.In general, these companies place orders for small quantities (5 to 10 in a batch).Many of the units in a batch are customized to a specific customer's requirements.

TFC has become successful because of its ability to develop new lines of designs in a timely fashion.These designs build on TFC's extensive experience with motor home users.They also build on TFC's knowledge of new technological advances and its ability to incorporate these advances into its designs.As a result, TFC has become the technological leader in this market.It is generally recognized that no one in the industry can match TFC's design and marketing knowledge base.

TFC is proud of its ability to design and build highly customized chassis.As John Stickley, its young and aggressive chief operating officer, is proud of pointing out, "Trail Frames has never met a customized chassis it didn't like." Complementing this focus on customization and speed, TFC has developed a culture of doing anything necessary to meet the needs of the customer.Changes are often introduced on the fly with an engineer taking a change down to the assembly line.In many cases, the bills of materials (the recipes for what goes into a given chassis)that were generated initially in engineering do not agree with the components and parts actually put into the chassis.

This approach has served TFC well for a number of years.However, recently sales for TFC have begun to level off.After visiting numerous customers in the field, John Stickley identified what he thought was the reason for this leveling off-the market for high-end, customized motor home chassis had been effectively saturated.There were only just so many customized motor homes that people wanted.Several of the major customers for TFC had strongly hinted that there was another market that TFC could enter that was consistent with its design strengths and its reputation.

Many of TFC's customers had noticed that there was a significant gap between the high-end motor homes that TFC served and the low-end market.The high-end consisted primarily of "pushers," and it began at $150,000; the low-end consisted of "pullers," and these products sold for between $35,000 and $70,000.That is, a motor home manufacturer would take an existing truck body (which consisted of the front end and the cab)and mount on it a motor home body.Obviously, there was a significant gap between the two markets.

One of TFC's major customers, Gulf Stream, approached TFC with an interesting proposal.It wanted TFC to design and build a low-end pusher chassis for this market.This chassis would go into a motor home that would cost between $75,000 and $90,000.In contrast to the current line of products, this chassis would not be customized.Rather, once the chassis was designed, it would not be changed.Production runs would go up from batches of five to batch runs of 100.Critical to success in this market would be cost and conformance to the schedule.If TFC could be the first to produce such a chassis, it would own the market.The financials were very attractive.Theoretically, it seemed easy for TFC to enter this market.All that had to be done was to take an existing chassis and to take out the "costs" by using less-expensive components.While TFC had never built such a chassis, there was no reason why it should not work.The only danger that the people at TFC could identify was that once it entered this market, it would be potentially competing with such firms as Ford, GM, and Toyota (major suppliers of the existing chassis).However, these firms supplied pullers (a chassis with the engine in front)-not pushers, like the proposed TFC product.In light of these issues, John was not sure whether this was the right market for TFc.What would you recommend to John Stickley that TFC should do to increase its sales and to stimulate demand?

Unlock Deck

Unlock for access to all 23 flashcards in this deck.

Unlock Deck

k this deck

18

When can a consumer be a critical consumer? In other words, when does it make sense to focus on consumers such as retail stores, distributors, or buyers, rather than on the end consumer?

Unlock Deck

Unlock for access to all 23 flashcards in this deck.

Unlock Deck

k this deck

19

A critical concept introduced in this chapter was that of the value proposition.Explore two competing products (e.g., RIM's Blackberry and Apple's Iphone).Identify the underlying value propositions present in these products and how this proposition is evident in the resulting products.

Unlock Deck

Unlock for access to all 23 flashcards in this deck.

Unlock Deck

k this deck

20

Core competencies are critical issues in operations management.Are there any instances in which a firm's core capabilities can be a liability rather than an asset?

Unlock Deck

Unlock for access to all 23 flashcards in this deck.

Unlock Deck

k this deck

21

Fit is critical to the development and maintenance of a successful operations strategy.Suppose that we are faced with a firm in which there is a lack of fit between the outcomes desired by the critical customer, the value proposition, and the firm's capabilities.What options are available to the firm in the short term when dealing with this lack of fit? What is the impact of the lack of fit? What are the implications of the firm trying to improve the fit?

Unlock Deck

Unlock for access to all 23 flashcards in this deck.

Unlock Deck

k this deck

22

Otis Toy Trains Explores the Supply Chain

Otis Toy Trains of Minneapolis, Minnesota, was a landmark company in the toy business.Since the 1900s, it had been responsible for building electrical and steam-driven toy trains.Since the 1950s, Otis trains had developed a major presence on children's television shows.Every person (especially boys)knew about Otis toy trains and nearly everyone wanted one.For many kids growing up in the 1960s to the 1980s, waking up on Christmas day and finding an Otis toy train set under the tree was a dream come true.However, the 1990s had not been good to Otis Toy Trains.The preferences of many children had changed.Instead of toys, what many children wanted was a game playing system (like Sony's PS2 or Microsoft Xbox or Nintindo's GameBoy Advanced).After a lot of investigation and assessment, the management at Otis had decided to reorient the product and the market.Consequently, it decided to target the adult male customer in the 30 to 50 year age bracket.This market was selected for several reasons.First, they had grown up with Otis toy trains and, as a result, Otis had excellent brand recognition among these buyers.Second, since Otis had decided to maintain the bulk of its production facilities in the areas around Minneapolis (the major production facility was located in Rochester, Minnesota), it needed a buyer who was willing to pay the premium now demanded by Otis Toy Trains for its products.Adult males in the 30 to 50 year age bracket typically had the income that supported luxury buys such as the Otis toy trains.Finally, the new target market was attractive because they tended to buy more than one system and they tended to buy a large number of accessories with their toy train purchases.

To sell to this new market, Otis introduced in 1995 the Otis Premium Trains of the Past series.This was a line of highly detailed, highly accurate trains drawn from critical points in North American history.The first launch consisted of the De Witt Clinton Rocket (the first train operated in the United States), the Abraham Lincoln train (a train model based on the train coaches that were used to transport the body of the recently assassinated President Lincoln from Washington, DC, to Springfield, IL, for final burial), the Zephyr (the famous streamlined train that ran between Chicago and Denver during the 1930s), and the Orange Blossom Special.Launched in limited numbers, this first series was an unqualified success.Subsequent launches were almost as successful.Over this time, the designers at Otis Toy Trains developed and refined the skill of identifying attractive train series and of designing products that were detailed, attractive, accurate, and highly evocative of past times.

By 2006, however, Otis Toy Trains found itself faced by the challenge of dealing with increasing labor costs.It was during this time period that the Joyous Luck Prosperity Toy Company (JLPTC)of China approached the management of the Otis Toy Train Company with a proposal that had already secured the support of Otis corporate accountants.They proposed to work closely with the designers of the Otis Toy Train Company with the goal of taking over the bulk of production of the Otis Premium Trains of the Past series.What JLPTC offered Otis was a landed price per unit that was between 40 to 60 percent lower than current manufacturing costs.This was a price that was too good to pass up.