Deck : 8 the Material Planning Process1

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Question

Unlock Deck

Sign up to unlock the cards in this deck!

Unlock Deck

Unlock Deck

1/28

Play

Full screen (f)

Deck : 8 the Material Planning Process1

1

Identify and discuss the different types of in-house production times defi ned in the material master.

In-house production time:

The in-house production time is the time taken to manufacture the materials in house and this is useful to compute the procurement of materials required by the companies.

The in-house production time includes the following three time elements such as,

• Setup time

• Processing time

• Interoperation time

Setup time:

Set up time is the time taken to set up the work centers needed for production.

Processing time:

Processing time is the time taken to finish up the operations successfully at the work centers.

Interoperation time:

Interoperation time is the time taken to shift the goods or materials from one work center to another.

The in-house production time is the time taken to manufacture the materials in house and this is useful to compute the procurement of materials required by the companies.

The in-house production time includes the following three time elements such as,

• Setup time

• Processing time

• Interoperation time

Setup time:

Set up time is the time taken to set up the work centers needed for production.

Processing time:

Processing time is the time taken to finish up the operations successfully at the work centers.

Interoperation time:

Interoperation time is the time taken to shift the goods or materials from one work center to another.

2

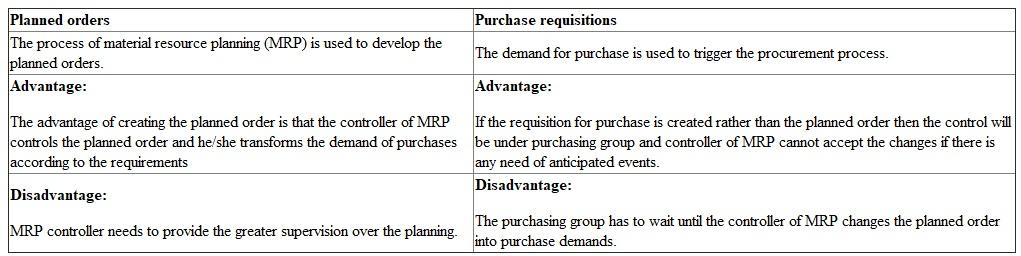

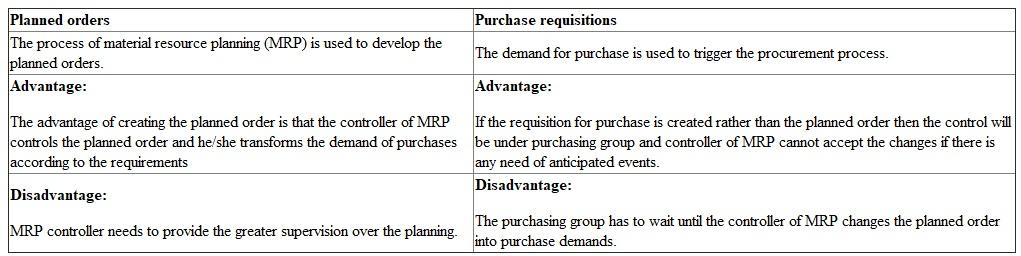

Assess the advantages and disadvantages of creating planned orders and purchase requisitions for externally procured materials.

Difference between the planned orders and purchase requisitions:

3

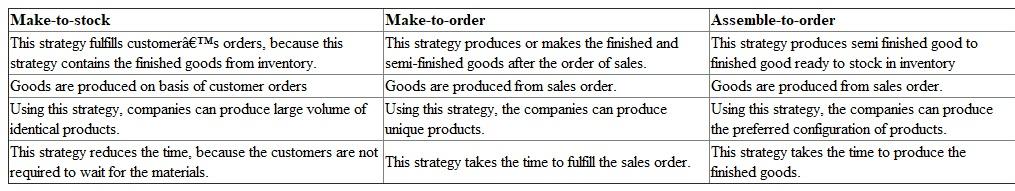

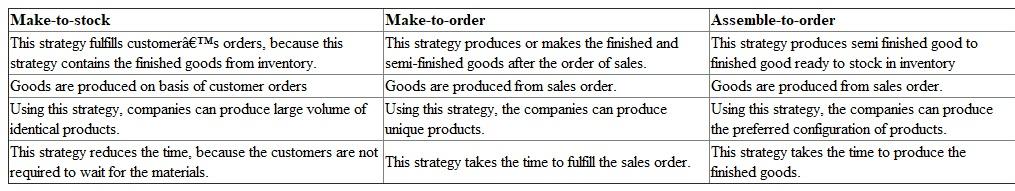

Compare and contrast the three production planning strategies discussed in this chapter.

Production planning strategy:

There are three production planning strategies; they are as follows:

• Make-to-stock

• Make-to-order

• Assemble-to-order

Comparison among the three production planning strategies:

There are three production planning strategies; they are as follows:

• Make-to-stock

• Make-to-order

• Assemble-to-order

Comparison among the three production planning strategies:

4

Defi ne MRP element.

Unlock Deck

Unlock for access to all 28 flashcards in this deck.

Unlock Deck

k this deck

5

Explain the process by which CIRs consume PIRs, and provide an example.

Unlock Deck

Unlock for access to all 28 flashcards in this deck.

Unlock Deck

k this deck

6

Discuss the different reporting tools that are useful in material planning.

Unlock Deck

Unlock for access to all 28 flashcards in this deck.

Unlock Deck

k this deck

7

What are product groups? What is the role of product groups in material planning?

Unlock Deck

Unlock for access to all 28 flashcards in this deck.

Unlock Deck

k this deck

8

Distinguish between the stock/requirements list and the MRP list.

Unlock Deck

Unlock for access to all 28 flashcards in this deck.

Unlock Deck

k this deck

9

Compare and contrast aggregation and disaggregation.

Unlock Deck

Unlock for access to all 28 flashcards in this deck.

Unlock Deck

k this deck

10

What is the role of the MRP controller in material planning?

Unlock Deck

Unlock for access to all 28 flashcards in this deck.

Unlock Deck

k this deck

11

Briefl y describe the steps in the material planning process in terms of the triggers, data, tasks, and outcomes.

Unlock Deck

Unlock for access to all 28 flashcards in this deck.

Unlock Deck

k this deck

12

Explain the functions and components of a planning table. Discuss the different methods of generating a production plan with a planning table.

Unlock Deck

Unlock for access to all 28 flashcards in this deck.

Unlock Deck

k this deck

13

What is the main objective of material planning? What are the basic ques-tions addressed by material planning?

Unlock Deck

Unlock for access to all 28 flashcards in this deck.

Unlock Deck

k this deck

14

What are the different options for disaggregating a sales plan or a produc-tion plan?

Unlock Deck

Unlock for access to all 28 flashcards in this deck.

Unlock Deck

k this deck

15

List and describe the steps in the material planning process.

Unlock Deck

Unlock for access to all 28 flashcards in this deck.

Unlock Deck

k this deck

16

Explain the differences between MRP and MPS.

Unlock Deck

Unlock for access to all 28 flashcards in this deck.

Unlock Deck

k this deck

17

Which master data are relevant for material planning?

Unlock Deck

Unlock for access to all 28 flashcards in this deck.

Unlock Deck

k this deck

18

Describe the tasks completed in the MRP step of the material planning process.

Unlock Deck

Unlock for access to all 28 flashcards in this deck.

Unlock Deck

k this deck

19

Defi ne and explain the relevance to material planning of the following data in the material master:

a. Procurement type

b. MRP type

c. Lot size key

d. Scheduling times

e. Planning time fence

f. BOM selection method

g. Availability check group

h. Strategy group

i. Consumption mode

a. Procurement type

b. MRP type

c. Lot size key

d. Scheduling times

e. Planning time fence

f. BOM selection method

g. Availability check group

h. Strategy group

i. Consumption mode

Unlock Deck

Unlock for access to all 28 flashcards in this deck.

Unlock Deck

k this deck

20

Explain the different control parameters that determine the way the tasks in the MRP step are executed.

Unlock Deck

Unlock for access to all 28 flashcards in this deck.

Unlock Deck

k this deck

21

Defi ne and distinguish between consumption-based planning and materi-als requirements planning.

Unlock Deck

Unlock for access to all 28 flashcards in this deck.

Unlock Deck

k this deck

22

Discuss the different MRP processing keys.

Unlock Deck

Unlock for access to all 28 flashcards in this deck.

Unlock Deck

k this deck

23

Explain how reorder point planning works.

Unlock Deck

Unlock for access to all 28 flashcards in this deck.

Unlock Deck

k this deck

24

Describe the net requirements calculation.

Unlock Deck

Unlock for access to all 28 flashcards in this deck.

Unlock Deck

k this deck

25

Explain the differences between

a. Dependent requirements and independent requirements

b. Planned independent requirements (PIRs) and customer requirements (CIRs).

a. Dependent requirements and independent requirements

b. Planned independent requirements (PIRs) and customer requirements (CIRs).

Unlock Deck

Unlock for access to all 28 flashcards in this deck.

Unlock Deck

k this deck

26

Explain the scheduling process in MRP.

Unlock Deck

Unlock for access to all 28 flashcards in this deck.

Unlock Deck

k this deck

27

Explain the common time estimates included in the material master.

Unlock Deck

Unlock for access to all 28 flashcards in this deck.

Unlock Deck

k this deck

28

Defi ne and discuss the types of procurement proposals that can be cre-ated in MRP.

Unlock Deck

Unlock for access to all 28 flashcards in this deck.

Unlock Deck

k this deck