Introduction to Materials Management 8th Edition by Steve Chapman ,Tony Arnold ,Ann Gatewood ,Lloyd Clive

Edition 8ISBN: 978-0134156323

Introduction to Materials Management 8th Edition by Steve Chapman ,Tony Arnold ,Ann Gatewood ,Lloyd Clive

Edition 8ISBN: 978-0134156323 Exercise 6

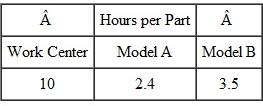

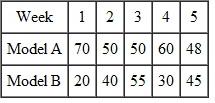

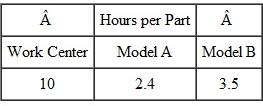

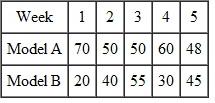

The Acme Widget Company makes widgets in two models, and the bottleneck operation is in work center 10. Following is the resource bill (in hours per part).  The master production schedule for the next 5 weeks is

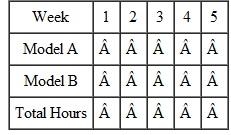

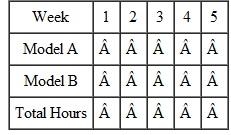

The master production schedule for the next 5 weeks is  a. Using the resource bill and the master production schedule, calculate the number of hours required in work center 10 for each of the 5 weeks. Use the following table to record the required capacity on the work center.

a. Using the resource bill and the master production schedule, calculate the number of hours required in work center 10 for each of the 5 weeks. Use the following table to record the required capacity on the work center.  b. If the available capacity at work station 10 is 260 hours per week, suggest possible ways of meeting the demand in week 3.

b. If the available capacity at work station 10 is 260 hours per week, suggest possible ways of meeting the demand in week 3.

The master production schedule for the next 5 weeks is

The master production schedule for the next 5 weeks is  a. Using the resource bill and the master production schedule, calculate the number of hours required in work center 10 for each of the 5 weeks. Use the following table to record the required capacity on the work center.

a. Using the resource bill and the master production schedule, calculate the number of hours required in work center 10 for each of the 5 weeks. Use the following table to record the required capacity on the work center.  b. If the available capacity at work station 10 is 260 hours per week, suggest possible ways of meeting the demand in week 3.

b. If the available capacity at work station 10 is 260 hours per week, suggest possible ways of meeting the demand in week 3.Explanation

Using resource bill and MPS calculate nu...

Introduction to Materials Management 8th Edition by Steve Chapman ,Tony Arnold ,Ann Gatewood ,Lloyd Clive

Why don’t you like this exercise?

Other Minimum 8 character and maximum 255 character

Character 255