Business & Professional Ethics 7th Edition by Leonard Brooks,Paul Dunn

Edition 7ISBN: 978-1285182223

Business & Professional Ethics 7th Edition by Leonard Brooks,Paul Dunn

Edition 7ISBN: 978-1285182223 Exercise 30

In order to meet strong competition from Volkswagen as well as other foreign domestic subcompacts, Lee Iacocca, then president of Ford Motor Co., decided to introduce a new vehicle by 1970, to be known as the Pinto. The overall objective was to produce a car at or below 2,000 pounds with a price tag of $2,000 or less. Although preproduction design and testing normally requires about three-and-a-half years and the arrangement of actual production somewhat longer, design was started in 1968 and production commenced in 1970.

The Pinto project was overseen by Robert Alexander, vice president of car engineering, and was approved by Ford's Product Planning Committee, consisting of Iacocca, Alexander, and Ford's group vice president of car engineering, Harold MacDonald. The engineers throughout Ford who worked on the project "signed off" to their immediate supervisors, who did likewise in turn to their superiors, and so on to Alexander and MacDonald and, finally, Iacocca.

Many reports were passed up the chain of command during the design and approval process, including several outlining the results of crash tests, and a proposal to remedy the tendency for the car to burst into flames when rear-ended at 21 miles per hour. This tendency was caused by the placement of the car's gas tank between the rear axle and the rear bumper such that a rear-end collision was likely to drive the gas tank forward to rupture on a flange and bolts on a rear axle housing for the differential. The ruptured tank would then spew gas into the passenger compartment to be ignited immediately by sparks or a hot exhaust.

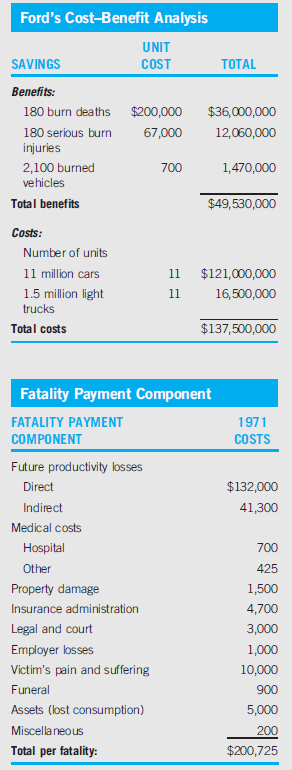

The remedies available to Ford included mounting the gas tank above the rear axle, which would cut down on trunk space, or installing a rubber bladder in the gas tank. Ford experimented with the installation of rubber bladders but apparently decided they were not cost-effective. Later, as part of a successful lobby effort against government regulations for mandatory crash tests (crash tests were delayed eight years, until 1977), Ford's cost-benefit analysis came to light in a company study entitled "Fatalities Associated with Crash-Induced Fuel Leakage and Fires." As the details previously outlined show, the costs of installing the rubber bladder vastly exceeded the benefits.

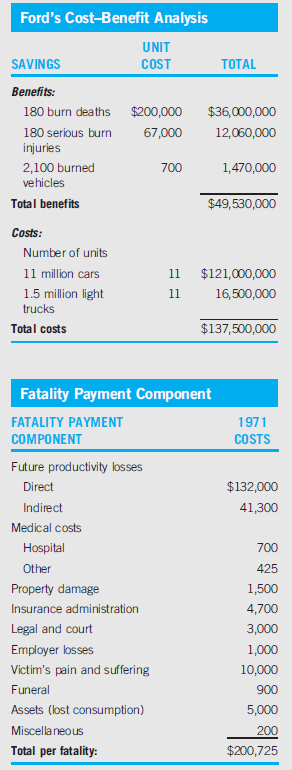

Ford took the $200,000 figure for the cost of a death from a study of the National Highway Traffic Safety Administration, which used the estimates in the table on the previous page.

What faults can you identify in Ford's cost-benefit analysis?

The Pinto project was overseen by Robert Alexander, vice president of car engineering, and was approved by Ford's Product Planning Committee, consisting of Iacocca, Alexander, and Ford's group vice president of car engineering, Harold MacDonald. The engineers throughout Ford who worked on the project "signed off" to their immediate supervisors, who did likewise in turn to their superiors, and so on to Alexander and MacDonald and, finally, Iacocca.

Many reports were passed up the chain of command during the design and approval process, including several outlining the results of crash tests, and a proposal to remedy the tendency for the car to burst into flames when rear-ended at 21 miles per hour. This tendency was caused by the placement of the car's gas tank between the rear axle and the rear bumper such that a rear-end collision was likely to drive the gas tank forward to rupture on a flange and bolts on a rear axle housing for the differential. The ruptured tank would then spew gas into the passenger compartment to be ignited immediately by sparks or a hot exhaust.

The remedies available to Ford included mounting the gas tank above the rear axle, which would cut down on trunk space, or installing a rubber bladder in the gas tank. Ford experimented with the installation of rubber bladders but apparently decided they were not cost-effective. Later, as part of a successful lobby effort against government regulations for mandatory crash tests (crash tests were delayed eight years, until 1977), Ford's cost-benefit analysis came to light in a company study entitled "Fatalities Associated with Crash-Induced Fuel Leakage and Fires." As the details previously outlined show, the costs of installing the rubber bladder vastly exceeded the benefits.

Ford took the $200,000 figure for the cost of a death from a study of the National Highway Traffic Safety Administration, which used the estimates in the table on the previous page.

What faults can you identify in Ford's cost-benefit analysis?

Explanation

There are a number of limitations to the...

Business & Professional Ethics 7th Edition by Leonard Brooks,Paul Dunn

Why don’t you like this exercise?

Other Minimum 8 character and maximum 255 character

Character 255