Accounting for Decision Making and Control 6th Edition by Jerold Zimmerman

Edition 6ISBN: 9780071283700

Accounting for Decision Making and Control 6th Edition by Jerold Zimmerman

Edition 6ISBN: 9780071283700 Exercise 24

Vangard Inc. manufactures shafts for golf clubs. The shafts are sold to golf club manufacturing companies that attach the heads and grips to complete the club. Vangard makes two types of shafts: steel and beryllium. The beryllium shaft is a steel shaft with small amounts of beryllium alloy added to give the shaft a distinctive (and prestigious) copper color. The steel shaft accounts for 90 percent of unit sales and the beryllium shaft accounts for 10 percent. Vangard faces a very competitive market for steel shafts. There are four other domestic producers, and the Japanese have entered the market and are capturing an ever-increasing market share of steel shafts. The market for shafts is growing at 15 percent per year due to the growing popularity of golf, but Vangard's market share is dropping a percentage point per year and is now down to 23 percent.

Raw tube stock, either steel or beryllium, is purchased from a supplier. Vangard has two production processes: forming and tempering. The forming process takes the raw tube stock, cuts it to the desired lengths, and then crimps the shafts in various places to reduce the tube's diameter from the thicker end where the grip is attached down to the narrower diameter at the club head. Forming is a highly automated, continuous machining process. Once the machinery is adjusted, raw tube stock is fed in, cut, and sized, and crimped shafts emerge from the other end of the machinery.

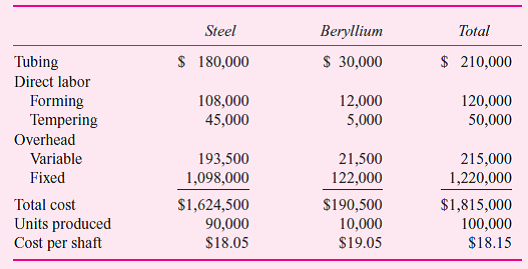

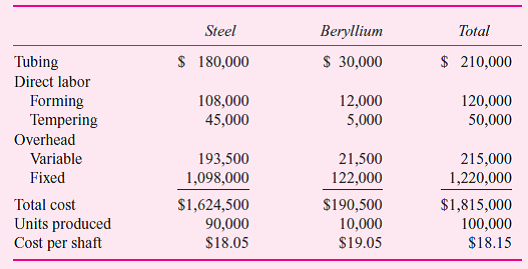

The second and final stage of the process is tempering. Here the cut and crimped shafts are first heated in special ovens and then cooled. This process hardens the steel and gives it the desired whip and flex necessary for the golf swing. Steel tubes are processed in batch sizes of 500 shafts per batch. Because of the higher temperatures needed for beryllium, only 100 beryllium shafts can be processed per batch. Currently, 180 batches of steel shafts and 100 batches of beryllium shafts are tempered per year. Annual capacity of the tempering process is 300 batches per year. Vangard Inc. produces 100,000 shafts per year. Its cost structure is as follows:

Overhead costs are applied to products based on the number of shafts produced. The costs of each type of shaft are as follows:

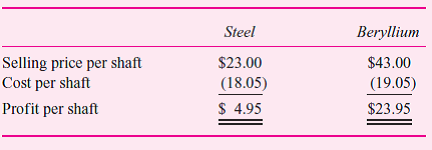

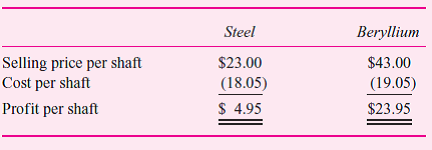

The profit margin on each type of shaft is as follows:

Vangard is one of only two companies currently manufacturing beryllium shafts. While the market for these shafts is small, it is growing. Management feels that it would be wise to become the dominant manufacturer of beryllium shafts and begin shifting more output into the beryllium market.

The Japanese, who make only steel shafts, are starting to put increasing pressure on steel shaft prices, often bidding large orders at less than $20 per shaft. Vangard management sees its niche as being the premier beryllium shaft maker.

Required:

a. Evaluate management's strategy to expand beryllium shaft output and become the dominant firm in beryllium shafts.

b. Evaluate Vangard's current cost accounting system.

Raw tube stock, either steel or beryllium, is purchased from a supplier. Vangard has two production processes: forming and tempering. The forming process takes the raw tube stock, cuts it to the desired lengths, and then crimps the shafts in various places to reduce the tube's diameter from the thicker end where the grip is attached down to the narrower diameter at the club head. Forming is a highly automated, continuous machining process. Once the machinery is adjusted, raw tube stock is fed in, cut, and sized, and crimped shafts emerge from the other end of the machinery.

The second and final stage of the process is tempering. Here the cut and crimped shafts are first heated in special ovens and then cooled. This process hardens the steel and gives it the desired whip and flex necessary for the golf swing. Steel tubes are processed in batch sizes of 500 shafts per batch. Because of the higher temperatures needed for beryllium, only 100 beryllium shafts can be processed per batch. Currently, 180 batches of steel shafts and 100 batches of beryllium shafts are tempered per year. Annual capacity of the tempering process is 300 batches per year. Vangard Inc. produces 100,000 shafts per year. Its cost structure is as follows:

Overhead costs are applied to products based on the number of shafts produced. The costs of each type of shaft are as follows:

The profit margin on each type of shaft is as follows:

Vangard is one of only two companies currently manufacturing beryllium shafts. While the market for these shafts is small, it is growing. Management feels that it would be wise to become the dominant manufacturer of beryllium shafts and begin shifting more output into the beryllium market.

The Japanese, who make only steel shafts, are starting to put increasing pressure on steel shaft prices, often bidding large orders at less than $20 per shaft. Vangard management sees its niche as being the premier beryllium shaft maker.

Required:

a. Evaluate management's strategy to expand beryllium shaft output and become the dominant firm in beryllium shafts.

b. Evaluate Vangard's current cost accounting system.

Explanation

The two widely used method of allocating...

Accounting for Decision Making and Control 6th Edition by Jerold Zimmerman

Why don’t you like this exercise?

Other Minimum 8 character and maximum 255 character

Character 255