Contemporary Engineering Economics 6th Edition by Chan Park

Edition 6ISBN: 978-0134105598

Contemporary Engineering Economics 6th Edition by Chan Park

Edition 6ISBN: 978-0134105598 Exercise 22

Automotive engineers at H. Motor Co. are considering the laser blank welding (LBW) technique to produce a windshield frame rail blank. The engineers believe that, compared with the conventional sheet metal blanks, LBW would result in a significant savings as follows.

1. Scrap reduction through more efficient blank nesting on coil.

2. Scrap reclamation (weld scrap offal into a larger, usable blank).

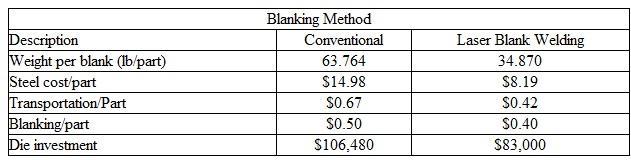

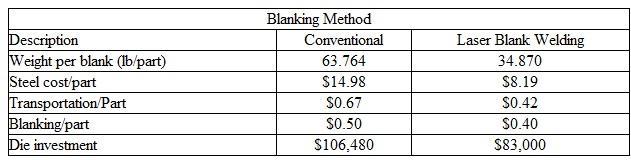

The use of a laser-welded blank provides a reduction in engineered scrap for the production of a window-frame rail blank. On the basis of an annual volume of 3,000 blanks, the engineers have estimated the financial data given in Table 1.

Table 1

The LBW technique appears to achieve significant savings, so the engineers are leaning toward adopting it. Since the engineers have had no previous experience with LBW, they are not sure whether producing the windshield frames in-house at this time is a good strategy. For this windshield frame, it may be cheaper to use the services of a supplier that has both the experience with, and the machinery for, laser blanking. The make-or-buy decision depends on two factors: the amount of new investment that is required in laser welding and whether additional machinery will be required for future products. Assume a lifetime of 10 years and an interest rate of 16% to recommend the best course of action. Assume also that the salvage value at the end of 10 years is estimated to be insignificant for either system. If H. Motor Co. considers the subcontracting option, what would be the acceptable range of contract bid (unit cost per part)

The LBW technique appears to achieve significant savings, so the engineers are leaning toward adopting it. Since the engineers have had no previous experience with LBW, they are not sure whether producing the windshield frames in-house at this time is a good strategy. For this windshield frame, it may be cheaper to use the services of a supplier that has both the experience with, and the machinery for, laser blanking. The make-or-buy decision depends on two factors: the amount of new investment that is required in laser welding and whether additional machinery will be required for future products. Assume a lifetime of 10 years and an interest rate of 16% to recommend the best course of action. Assume also that the salvage value at the end of 10 years is estimated to be insignificant for either system. If H. Motor Co. considers the subcontracting option, what would be the acceptable range of contract bid (unit cost per part)

1. Scrap reduction through more efficient blank nesting on coil.

2. Scrap reclamation (weld scrap offal into a larger, usable blank).

The use of a laser-welded blank provides a reduction in engineered scrap for the production of a window-frame rail blank. On the basis of an annual volume of 3,000 blanks, the engineers have estimated the financial data given in Table 1.

Table 1

The LBW technique appears to achieve significant savings, so the engineers are leaning toward adopting it. Since the engineers have had no previous experience with LBW, they are not sure whether producing the windshield frames in-house at this time is a good strategy. For this windshield frame, it may be cheaper to use the services of a supplier that has both the experience with, and the machinery for, laser blanking. The make-or-buy decision depends on two factors: the amount of new investment that is required in laser welding and whether additional machinery will be required for future products. Assume a lifetime of 10 years and an interest rate of 16% to recommend the best course of action. Assume also that the salvage value at the end of 10 years is estimated to be insignificant for either system. If H. Motor Co. considers the subcontracting option, what would be the acceptable range of contract bid (unit cost per part)

The LBW technique appears to achieve significant savings, so the engineers are leaning toward adopting it. Since the engineers have had no previous experience with LBW, they are not sure whether producing the windshield frames in-house at this time is a good strategy. For this windshield frame, it may be cheaper to use the services of a supplier that has both the experience with, and the machinery for, laser blanking. The make-or-buy decision depends on two factors: the amount of new investment that is required in laser welding and whether additional machinery will be required for future products. Assume a lifetime of 10 years and an interest rate of 16% to recommend the best course of action. Assume also that the salvage value at the end of 10 years is estimated to be insignificant for either system. If H. Motor Co. considers the subcontracting option, what would be the acceptable range of contract bid (unit cost per part)Explanation

This question doesn’t have an expert verified answer yet, let Quizplus AI Copilot help.

Contemporary Engineering Economics 6th Edition by Chan Park

Why don’t you like this exercise?

Other Minimum 8 character and maximum 255 character

Character 255