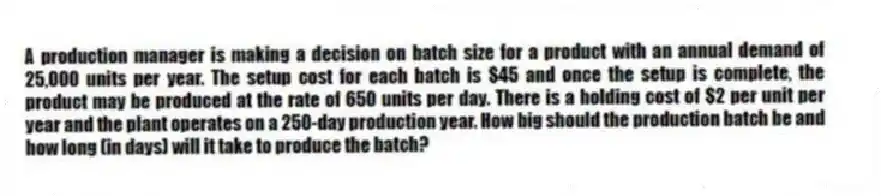

A production manager is making a decision on batch size for a product with an annual demand of 25,000 units per year. The setup cost for each batch is $45 and once the setup is complete, the product may be produced at the rate of 650 units per day. There is a holding cost of $2 per unit per year and the plant operates on a 250-day production year. How big should the production batch be and how long (in days) will it take to produce the batch?

Correct Answer:

Verified

Productio...

View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Q28: Sketch the economic production lot size (ELS)

Q29: In a one-period inventory model, the higher

Q30: Scenario C.2

Egan Schranz sells Klammelhoffer skis out

Q31: If demand exceeds the order quantity in

Q32: The closer the in-season and after season

Q34: When faced with a quantity discount situation,

Q35: In a one-period inventory model, the more

Q36: Use of the single-period model will maximize

Q37: A pencil supplier just introduced quantity discounts.

Q38: As an inventory manager, you must decide

Unlock this Answer For Free Now!

View this answer and more for free by performing one of the following actions

Scan the QR code to install the App and get 2 free unlocks

Unlock quizzes for free by uploading documents