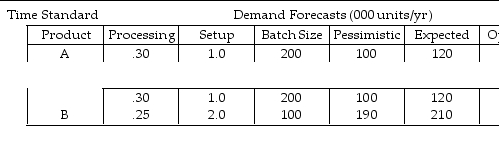

Larry's Wickets, Inc. is producing two types of products: A and B. Both are produced at the same machining operation. Because of demand uncertainties, the operations manager obtained three demand forecasts (pessimistic, expected, and optimistic). The demand forecasts, batch sizes (units/batch), processing times (hr/unit), and setup times (hr/batch) follow.

The machines operate on two 8- hour shifts, 5 days per week, and 50 weeks per year. The manager wants to maintain a 20 percent capacity cushion.

a. What is the minimum number of hours required of the machining equipment for the next year?

b. How many hours of capacity can the company expect from each machine?

c. What is the minimum number of machines needed (assuming no reliance on short- term options)?

d. What is the maximum number of machines needed (assuming no reliance on short- term options)?

Correct Answer:

Verified

Scenarios that can be met wi...

View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Q59: What factors should be considered when selecting

Q133: Identify the three interrelated factors that implicitly

Q134: Explain the relationship between throughput time and

Q135: The base case concept is to do

Q136: What is the capacity cushion and how

Q137: According to the theory of constraints (TOC),

Q138: Aggregate stock is any stock of items

Q139: Explain the distinction between blocked and starved

Q141: Explain the distinction between input and output

Q143: Explain the distinction between effective capacity and

Unlock this Answer For Free Now!

View this answer and more for free by performing one of the following actions

Scan the QR code to install the App and get 2 free unlocks

Unlock quizzes for free by uploading documents