SCENARIO 19-4

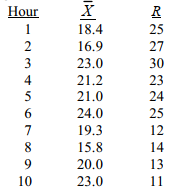

A factory supervisor is concerned that the time it takes workers to complete an important production task (measured in seconds) is too erratic and adversely affects expected profits.The supervisor proceeds by randomly sampling 5 individuals per hour for a period of 10 hours.The sample mean and range for each hour are listed below. She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds,respectively.

She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds,respectively.

-Referring to Scenario 19-4,suppose the supervisor constructs an R chart to see if the variability in collection times is in-control.What is the center line of this R chart?

A) 20.00

B) 20.56

C) 20.40

D) 24.00

Correct Answer:

Verified

Q35: SCENARIO 19-3

A quality control analyst for a

Q36: SCENARIO 19-4

A factory supervisor is concerned that

Q37: The control limits are based on the

Q38: SCENARIO 19-3

A quality control analyst for a

Q39: SCENARIO 19-3

A quality control analyst for a

Q41: Common causes of variation represent variation due

Q42: In the United States,the control limits on

Q43: The cause of variation that can be

Q44: Common causes of variation are correctable without

Q45: SCENARIO 19-5

A manufacturer of computer disks took

Unlock this Answer For Free Now!

View this answer and more for free by performing one of the following actions

Scan the QR code to install the App and get 2 free unlocks

Unlock quizzes for free by uploading documents