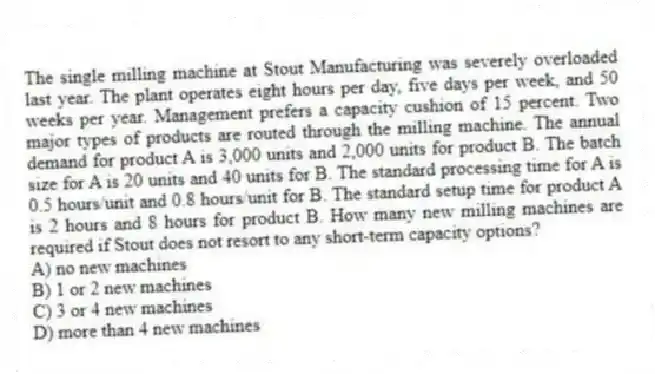

The single milling machine at Stout Manufacturing was severely overloaded last year. The plant operates eight hours per day, five days per week, and 50 weeks per year. Management prefers a capacity cushion of 15 percent. Two major types of products are routed through the milling machine. The annual demand for product A is 3,000 units and 2,000 units for product B. The batch size for A is 20 units and 40 units for B. The standard processing time for A is 0.5 hours/unit and 0.8 hours/unit for B. The standard setup time for product A is 2 hours and 8 hours for product B. How many new milling machines are required if Stout does not resort to any short-term capacity options?

A) no new machines

B) 1 or 2 new machines

C) 3 or 4 new machines

D) more than 4 new machines

Correct Answer:

Verified

Q64: Table 4.1

The Union Manufacturing Company is producing

Q65: A standard work year is 2,000 hours

Q66: The Northern Manufacturing Company is producing products

Q67: A standard work year is 2,000 hours

Q68: A standard work year is 2,080 hours

Q70: Sleep Tight Motel has the opportunity to

Q71: When a firm makes a long-term capacity

Q72: A well-educated operations manager used the capacity

Q73: The lock box department at Bank 21

Q74: A company's production facility, consisting of two

Unlock this Answer For Free Now!

View this answer and more for free by performing one of the following actions

Scan the QR code to install the App and get 2 free unlocks

Unlock quizzes for free by uploading documents