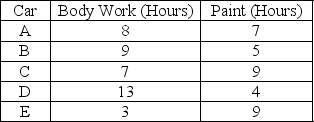

The operations manager of a body and paint shop has five cars to schedule for repair. He would like to minimize the throughput time (makespan) to complete all work on these cars. Each car requires body work prior to painting. The estimates of the times required to do the body and paint work on each are as follows:

(a) Use Johnson's rule to sequence these five jobs for minimum total duration. Show your work in determining the job sequence.

(a) Use Johnson's rule to sequence these five jobs for minimum total duration. Show your work in determining the job sequence.

(b) The optimal sequence is ________.

(c) Chart the progress of the five jobs in this optimal sequence.

(d) After how many hours will all jobs be completed?

Correct Answer:

Verified

View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Q93: Jack's Refrigeration Repair is under contract to

Q94: The time between the release of a

Q95: The following jobs are waiting to be

Q96: At Morgan's Transformer Rebuilding, five jobs are

Q97: What does Johnson's rule do?

Q99: The priority rule that appears fair to

Q100: In retail outlets, customers are usually processed

Q101: A recent advance in short-term scheduling that

Q102: Given the table below, find the sequence

Q103: Finite capacity scheduling provides the user with

Unlock this Answer For Free Now!

View this answer and more for free by performing one of the following actions

Scan the QR code to install the App and get 2 free unlocks

Unlock quizzes for free by uploading documents