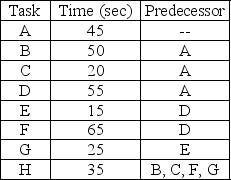

The process design team at a manufacturer has broken an assembly process into eight basic steps,each with a required time,and predecessor as shown in the table.There are 7.5 productive hours available in a day and the manufacturer wishes to produce 400 units.Balance the line by assigning tasks to workstations to fill up as much takt time as possible.Break ties by assigning the longest task first.What task(s) should be assigned at the third workstation?

A) B and E

B) D

C) C,E,and G

D) F

Correct Answer:

Verified

Q7: _ gets its name from the fact

Q15: A(n)_ is a highly automated batch process

Q21: According to the law of variability, the

Q29: _ are products that are customized only

Q30: Why are process decisions important?

Q32: A cellular layout is essentially the opposite

Q41: In a service blueprint,the two layers the

Q44: The maximum allowable cycle time for a

Q48: These three tables show the floor layout

Q58: Service operations compete and position themselves in

Unlock this Answer For Free Now!

View this answer and more for free by performing one of the following actions

Scan the QR code to install the App and get 2 free unlocks

Unlock quizzes for free by uploading documents