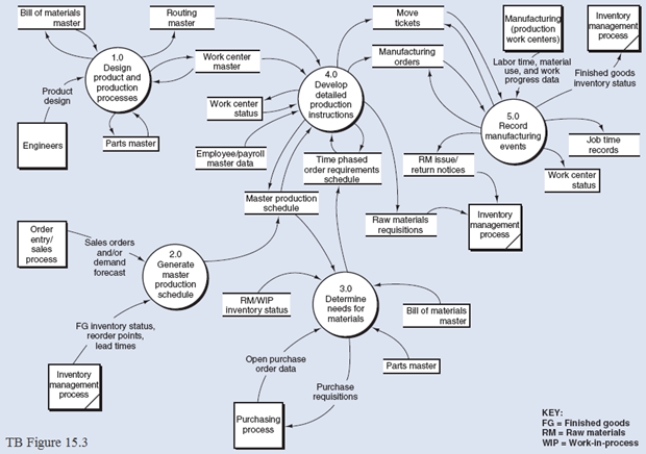

The process within TB Figure 15.3, Bubble 3.0 might be described as follows: After the master production schedule is determined, an important step in completing the production in a timely manner is identifying, ordering, and receiving materials. Materials requirements planning is a process that uses bills of material, raw material and WIP inventory status data, open order data, and the master production schedule to calculate a time-phased order requirements schedule for materials and subassemblies. The schedule shows the time period when a manufacturing order or purchase order should be released so that the subassemblies and raw materials will be available when needed. The process involves working backward from the date production is to begin to determine the timing for manufacturing subassemblies and then moving back further to determine the date that orders for materials must be issued into the purchasing process. In an enterprise system, this process is performed automatically, using a variety of data from the enterprise database including:

*Bills of materials, showing the items and quantites required as developed by engineerng.

*Parts master data, which contains infarmation about part number, description, unit of measure, where used, arder policy. lead tine, and safety stack.

*Raw materials and WIP inventory status data showing the current quantities an hand and quantities already reserved for production for the materials and subassemblies.

*Open purchase order data showring the existing arders for materials. The process begins by exploding the bill of materials to determine the total of each component required to manufacture a given quantity of an upper level assembly or a subassembly specified in the master production schedule. Based on lead time data for producing and ordering materials and subassembly requirements are output in a time-phased order requirements schedule. Based on this schedule, and open PO data, purchase requisitions are generated and sent to purchasing.

Required:

Refer to TB Figure 15.3. Prepare a Level 1 data flow diagram for the materials requirements planning process only.

Correct Answer:

Verified

Q100: The _ process uses the information from

Q101: The process of exploding the BOM results

Q102: _ tags can be attached to inventory

Q103: The _ process is devoted to monitoring

Q104: TB Figure 15.5 displays a Level 0

Q106: A(n) _ is the assigned location where

Q107: The _ specifies the operations necessary to

Q108: _ data marks the end of the

Q109: _ is the process of comparing actual

Q110: The _ describes each work center available

Unlock this Answer For Free Now!

View this answer and more for free by performing one of the following actions

Scan the QR code to install the App and get 2 free unlocks

Unlock quizzes for free by uploading documents