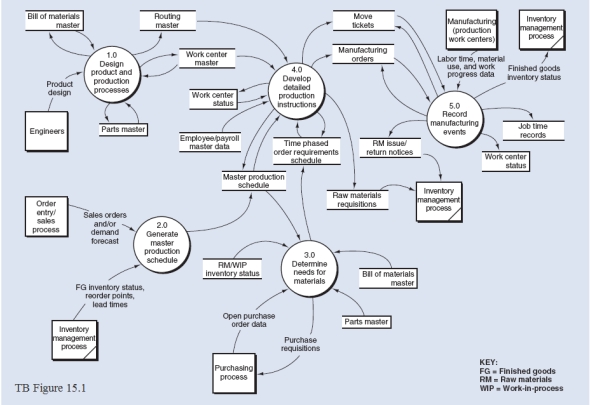

(TB Figure 15.1 Bubble 1.0)  Consistent with the value chain concept, the IPP begins with the design of the product and production processes.Activity based costing can be used to develop estimates of the future cost of producing new products as well as potential cost changes from product or design changes.The entire design process is automated through the use of computer-aided design and computer-aided engineering.With the use of enterprise systems, the electronic designs produced using CAD/CAE become the basis for developing detailed production schedules (step 2.0) as well as the electronic control of production machines.In addition to the detailed product design, the CAD/CAE process results in several data stores of information that are used later in the IPP:

Consistent with the value chain concept, the IPP begins with the design of the product and production processes.Activity based costing can be used to develop estimates of the future cost of producing new products as well as potential cost changes from product or design changes.The entire design process is automated through the use of computer-aided design and computer-aided engineering.With the use of enterprise systems, the electronic designs produced using CAD/CAE become the basis for developing detailed production schedules (step 2.0) as well as the electronic control of production machines.In addition to the detailed product design, the CAD/CAE process results in several data stores of information that are used later in the IPP:

-Bill of materials (BOM): The BOM provides the basis for later orders of raw materials (bubble 3.0) when a finished good is to be produced.-Part master: The parts master or raw materials inventory master lists the detailed specifications of each raw materials item.An engineer must specify the information for the new material in the parts master when a new part is used in product design.Often, existing parts will be used in new products to reduce needed ordering and carrying costs for the inventory.-Routing master: The routing master specifies the operations necessary to complete a subassembly or finished good, and the sequence of these operations.The routing master also includes the machining tolerances; the tools, jigs, and fixtures required and the time allowed for each operation.The routing master is vital to developing detailed production instructions (bubble 4.0 in Figure 15.1).Computer aided process planning (CAPP), is often used in developing the routing master for developing new products.CAPP is an automated decision support system that generates manufacturing operations instructions and routings based on information about machinery requirements and capabilities.-Work center master: The work center master describes each work center available for producing products.A work station is the assigned location where a worker performs their job.A group of similar work stations constitutes a work center.When new products require new machines or production activities, a new record in the work center master must be created.Refer to TB Figure 15.1.Prepare a Level 1 data flow diagram for the product and production process design process only.

Correct Answer:

Verified

Q87: _ is an integrated decision support system

Q89: The process of _ involves determining the

Q96: The _ system is concerned with the

Q98: The _ process uses the information from

Q99: _ is a process that uses bills

Q102: _ tags can be attached to inventory

Q104: TB Figure 15.5 displays a Level 0

Q108: _ data marks the end of the

Q109: _ is the process of comparing actual

Q111: _ is the accumulation of data on

Unlock this Answer For Free Now!

View this answer and more for free by performing one of the following actions

Scan the QR code to install the App and get 2 free unlocks

Unlock quizzes for free by uploading documents