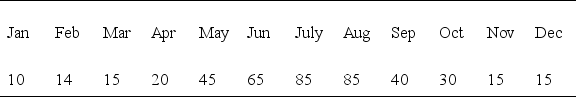

Surfs Up produces high-end surfboards.A challenge faced by Surfs Up is that their demand is highly seasonal.Demand exceeds production capacity during the warm summer months,but is very low in the winter months.To meet the high demand during the summer,Surfs Up typically produces more surfboards than are needed in the winter months and then carries inventory into the summer months.Their production facility can produce at most 50 boards per month using regular labor at a cost of $125 each.Up to 10 additional boards can be produced by utilizing overtime labor at a cost of $135 each.The boards are sold for $200.Because of storage cost and the opportunity cost of capital,each board held in inventory from one month to the next incurs a cost of $5 per board.Since demand is uncertain,Surfs Up would like to maintain an ending inventory (safety stock)of at least 10 boards during the warm months (May-September)and at least 5 boards during the other months (October-April).It is now the start of January and Surfs Up has 5 boards in inventory.The forecast of demand over the next 12 months is shown in the table below.Formulate and solve a linear programming model in a spreadsheet to determine how many surfboards should be produced each month to maximize total profit.

Correct Answer:

Verified

View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Q1: The kitchen manager for Sing Sing Prison

Q2: Comfortable Hands is a company which features

Q3: Dwight and Hattie have run the family

Q4: Back Savers is a company that produces

Q5: The marketing group for a cell phone

Q6: Cool Power produces air conditioning units for

Q7: The Weigelt Corporation has three branch plants

Q9: Slim-Down Manufacturing makes a line of nutritionally

Unlock this Answer For Free Now!

View this answer and more for free by performing one of the following actions

Scan the QR code to install the App and get 2 free unlocks

Unlock quizzes for free by uploading documents