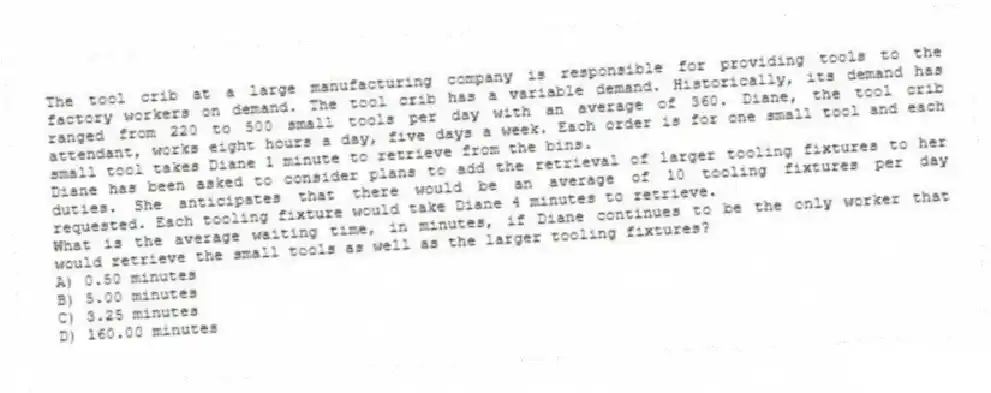

The tool crib at a large manufacturing company is responsible for providing tools to the factory workers on demand. The tool crib has a variable demand. Historically, its demand has ranged from 220 to 500 small tools per day with an average of 360. Diane, the tool crib attendant, works eight hours a day, five days a week. Each order is for one small tool and each small tool takes Diane 1 minute to retrieve from the bins.

Diane has been asked to consider plans to add the retrieval of larger tooling fixtures to her duties. She anticipates that there would be an average of 10 tooling fixtures per day requested. Each tooling fixture would take Diane 4 minutes to retrieve.

What is the average waiting time, in minutes, if Diane continues to be the only worker that would retrieve the small tools as well as the larger tooling fixtures?

A) 0.50 minutes

B) 5.00 minutes

C) 3.25 minutes

D) 160.00 minutes

Correct Answer:

Verified

Q114: The average waiting time is the average

Q115: Customer response time is the time it

Q116: Alex is injured and rushed to Care

Q117: Ventaz Corp manufactures small windows for back

Q118: Manufacturing lead time is the sum of

Q120: Manufacturing Cycle Efficiency (MCE) = Value-added Manufacturing

Q121: One of the ways to increase capacity

Q122: Longer manufacturing cycle times can result in

Q123: Increasing the capacity of a bottleneck resource

Q124: Norton's Convenience store has a variable demand.

Unlock this Answer For Free Now!

View this answer and more for free by performing one of the following actions

Scan the QR code to install the App and get 2 free unlocks

Unlock quizzes for free by uploading documents