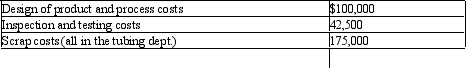

Quality improvement.Trimline Frames makes bicycle frames in two processes,tubing and welding.The tubing process has a capacity of 50,000 units per year;welding has a capacity of 75,000 units per year.Cost information follows:

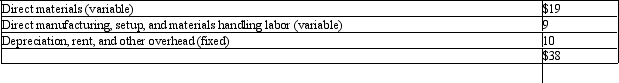

The company enjoys high demand for its products.Trimline Frames can sell whatever output it can produce for the market price of $60 per frame.Trimline Frames can start only 50,000 units into production in the tubing department because of capacity constraints on the tubing machines.The company scraps all defective units produced in the tubing department.Of the 50,000 units started in the tubing operation,5,000 units (10 percent)are scrapped at the end of the production process.Scrap costs,based on total (fixed and variable)manufacturing costs incurred in the tubing operation,equal $38 per unit as follows:

The "$10 fixed cost" is the portion of the total fixed costs of $500,000 allocated to each unit,whether good or defective.The good units from the tubing department are sent to the welding department.Variable manufacturing costs in the welding department are $3.00 per unit.There is no scrap in the welding department.Therefore,Trimline Frames' total sales quantity equals the tubing department's output.Trimline Frames incurs no other variable costs.Trimline Frames' designers have discovered that using a different type of material in the tubing operation would reduce scrap to zero,but it would increase the variable costs per unit in the tubing department by $1.50.Recall that only 50,000 units can be started each year.

Required:

a.What is the additional direct materials cost of implementing the new method?

b.What is the additional benefit to Trimline Frames from using the new material and improving quality?

c.Should Trimline Frames use the new materials?

d.What other nonfinancial and qualitative factors should Trimline Frames consider in making the decision?

(Designer Frames;Quality improvement. )

Correct Answer:

Verified

b.Her...

View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Q136: What are the four quality costing categories?

Q137: How do traditional managerial accounting systems need

Q138: Break-even time.Weldon Company's research and development department

Q139: Distinguish between the traditional view of quality

Q140: Assume Fruit Delight Beverages has discovered a

Q141: Break-even time,working backward.Montana Instruments is considering manufacturing

Q142: Reporting costs of quality.Fallows Corporation manufactures freezers.The

Q143: At Bingham Dry Goods,the strategy for success

Q144: Reporting costs of quality.Nichols Corporation manufactures freezers.The

Q146: Break-even time.Hampton Corporation's research and development department

Unlock this Answer For Free Now!

View this answer and more for free by performing one of the following actions

Scan the QR code to install the App and get 2 free unlocks

Unlock quizzes for free by uploading documents