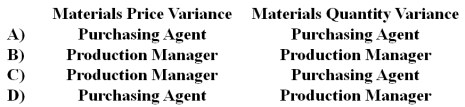

The purchasing agent of the Clampett Company ordered materials of lower quality in an effort to economize on price and in response to the demands of the production manager due to a mistake in production scheduling.The materials were shipped by airfreight at a rate higher than that ordinarily charged for shipment by truck,resulting in an unfavorable materials price variance.The lower quality material proved to be unsuitable on the production line and resulted in excessive waste.In this situation,who should be held responsible for the materials price and quantity variances?

A) Option A

B) Option B

C) Option C

D) Option D

Correct Answer:

Verified

Q11: The general model for calculating a

Q12: Todco planned to produce 3,000 units of

Q13: The standard quantity per unit for direct

Q14: When more hours of labor time are

Q15: Which department should usually be held responsible

Q17: The materials price variance is computed by

Q18: Tower Company planned to produce 3,000 units

Q19: If the labor efficiency variance is unfavorable,then

A)actual

Q20: A labor efficiency variance resulting from the

Q21: The following standards for variable manufacturing overhead

Unlock this Answer For Free Now!

View this answer and more for free by performing one of the following actions

Scan the QR code to install the App and get 2 free unlocks

Unlock quizzes for free by uploading documents