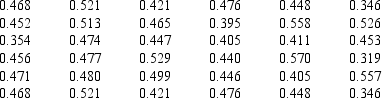

At a certain manufacturing plant, a machine produces ball bearings that should have a diameter of 0.500 mm. If the machine produces ball bearings that are either too small or too large, the ball bearings must be scrapped. Every hour, a quality control manager takes a random sample of 36 ball bearings to test to see if the process is "out of control" (i.e. to test to see if the average diameter differs from 0.500 mm). Assume that the process is maintaining the desired standard deviation of .06 mm. The results from the latest sample follow:

At a .01 level of significance, use Excel to test whether the process is "out of control."

At a .01 level of significance, use Excel to test whether the process is "out of control."

Correct Answer:

Verified

View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Q63: From a population of cans of coffee

Q84: Exhibit 9-6

A random sample of 100 people

Q88: Exhibit 9-6

A random sample of 100 people

Q89: A carpet company advertises that it will

Q90: Exhibit 9-6

A random sample of 100 people

Q91: A sample of 16 cookies is taken

Q92: The average gasoline price of one

Q93: The sponsors of televisions shows targeted at

Q99: Exhibit 9-6

A random sample of 100 people

Q100: Exhibit 9-6

A random sample of 100 people

Unlock this Answer For Free Now!

View this answer and more for free by performing one of the following actions

Scan the QR code to install the App and get 2 free unlocks

Unlock quizzes for free by uploading documents