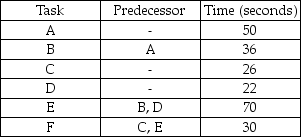

A company is designing a product layout for a new product.It plans to use this production line eight hours a day in order to meet a schedule of 400 units per day.The tasks necessary to produce this product are detailed in the table below.

a.Draw the network described in the table.

a.Draw the network described in the table.

b.Without regard to a production schedule,what is the minimum possible cycle time (in seconds)for this situation; what is the maximum?

c.What is the required cycle time (in seconds)in order to meet the schedule?

d.What is the theoretical minimum number of workstations needed to meet the schedule?

e.Balance this line using longest processing time.

f.What is the efficiency of the balance obtained in part e?

Correct Answer:

Verified

View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Q122: Four hundred and eighty minutes of production

Q135: An assembly line consists of 158 tasks

Q141: Hemo-tech,Inc.,a biomedical technology and research laboratory,produces a

Q283: If a layout problem is solved by

Q296: Which of the following is NOT a

Q301: Explain what the purpose of assembly-line balancing

Q307: Assembly line balancing has just been used

Q308: _ is the maximum time that the

Q315: Identify the formulas for the following terms

Q319: What are the advantages and disadvantages of

Unlock this Answer For Free Now!

View this answer and more for free by performing one of the following actions

Scan the QR code to install the App and get 2 free unlocks

Unlock quizzes for free by uploading documents