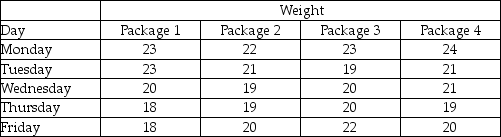

A quality analyst wants to construct a sample mean chart for controlling a packaging process.He knows from past experience that when the process is operating as intended,packaging weight is normally distributed with a mean of twenty ounces,and a process standard deviation of two ounces.Each day last week,he randomly selected four packages and weighed each.The data from that activity appear below.

(a)If he sets an upper control limit of 21 and a lower control limit of 19 around the target value of twenty ounces,the control chart is based on what value of z?

(a)If he sets an upper control limit of 21 and a lower control limit of 19 around the target value of twenty ounces,the control chart is based on what value of z?

(b)With the UCL and LCL of part a,what do you conclude about this process-is it in control?

Correct Answer:

Verified

View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Q64: Examine the Statistical Process Control outputs below.Answer

Q65: The mean and standard deviations for a

Q67: Repeated sampling of a certain process shows

Q68: Larry's boat shop wants to monitor the

Q70: The defect rate for a product has

Q71: McDaniel Shipyards wants to develop a control

Q73: A small,independent amusement park collects data on

Q74: Cartons of Plaster of Paris are supposed

Q192: What is the difference between natural and

Q200: A local manufacturer supplies you with parts,

Unlock this Answer For Free Now!

View this answer and more for free by performing one of the following actions

Scan the QR code to install the App and get 2 free unlocks

Unlock quizzes for free by uploading documents