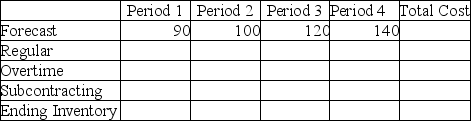

The demand forecast for the next four periods is 90,100,120,and 140 units respectively.The plant has a regular capacity of 100 units per period,an overtime capacity of 10 units per period,and a subcontractor capacity of 5 units per period.There is a $5 per unit charge for regular production,an $8 per unit charge for overtime production,and a $9 per unit charge for subcontracting.The holding cost is $3 per unit per period,no shortages are allowed and the company has 5 units in inventory at the start of the planning period.

a.How many units should be produced using overtime?

b.How many units should be produced using subcontracting?

c.What is the total inventory holding cost?

d.What is the lowest total plan cost?

e.Fill out this table showing the number of units made by period using each type of production and the resulting inventory at the end of each period.

Correct Answer:

Verified

View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Q101: Scheduling involves generating a work schedule for

Q102: Flow time is only the time a

Q104: Jobs processed using the first-come-first-served priority rule

Q106: Job flow time is defined as the:

A)

Q107: The purpose of a rotating schedule is

Q108: A service firm uses a level utilization

Q110: A fixed schedule gives each employee the

Q115: The Gantt chart can be used as

Q116: Table 10.6

Bluebird University provides tutoring services for

Q118: The workforce schedule:

A) determines when employees work.

B)

Unlock this Answer For Free Now!

View this answer and more for free by performing one of the following actions

Scan the QR code to install the App and get 2 free unlocks

Unlock quizzes for free by uploading documents