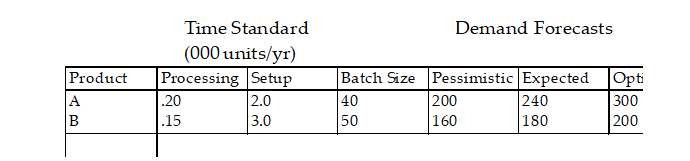

Table 5.2

High Tech, Inc. is producing two types of products: A and B. Both are produced at the same sawing operation. Because of demand uncertainties, the operations manager obtained three demand forecasts (pessimistic, expected, and optimistic) . The demand forecasts, batch sizes (units/batch) , processing times (hr/unit) , and setup times (hr/batch) follow.

The sawing machines operate on two 8-hour shifts, 5 days per week, and 50 weeks per year. The manager wants to maintain a 10 percent capacity cushion.

-Using the information from Table 5.2, what is the maximum number of machines needed (assuming no reliance on short- term option) ?

A) less than or equal to 25

B) more than 25 but less than or equal to 28

C) more than 28 but less than or equal to 31

D) more than 31

Correct Answer:

Verified

Q1: The Northern Manufacturing Company is producing

Q2: Table

Q3: A wait- and- see strategy in regard

Q4: Table 5.2

High Tech, Inc. is producing two

Q5: What information would managers use to choose

Q7: Which of the following is NOT a

Q8: The single milling machine at Stout Manufacturing

Q9: Which one of the following is NOT

Q10: Table 5.2

High Tech, Inc. is producing two

Q11: Up, Up & Away is a producer

Unlock this Answer For Free Now!

View this answer and more for free by performing one of the following actions

Scan the QR code to install the App and get 2 free unlocks

Unlock quizzes for free by uploading documents