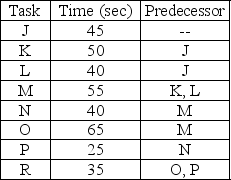

The process design team at a manufacturer has broken an assembly process into eight basic steps,each with a required time,and predecessor as shown in the table.There are 8 productive hours available in a day and the manufacturer wishes to produce 400 units.

-Balance the line according to the longest operation rule and calculate the percent idle time.Using the same arrangement of tasks at work stations,what is the greatest output that can be achieved in an eight-hour day and what is the percent idle time of this design?

Correct Answer:

Verified

View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Q24: What is a cellular layout and what

Q31: _ products involve no customization but _

Q41: What are the four levels of customization

Q49: As the degree of customer contact decreases,more

Q57: Define the term service package and describe

Q57: The _ includes all value-added physical and

Q59: Sketch the product-process matrix and discuss the

Q61: A manufacturer needs to produce 300 coffee

Q63: What is the optimal location for these

Q78: Define the terms front room and back

Unlock this Answer For Free Now!

View this answer and more for free by performing one of the following actions

Scan the QR code to install the App and get 2 free unlocks

Unlock quizzes for free by uploading documents