Prior to installing a JIT system, Plasticize Company used machine hours to assign maintenance costs to its three products of 3-inch, 5-inch, and 7-inch plastic tubing.

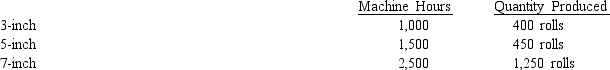

The maintenance costs totaled $120,000 per year. The machine hours used by each product and the quantity produced of each product are as follows:

After installing JIT, three manufacturing cells were created and the cell workers were trained to perform maintenance. Maintenance costs for the three cells still totaled $120,000; however, these costs are now traceable to each cell.

After installing JIT, three manufacturing cells were created and the cell workers were trained to perform maintenance. Maintenance costs for the three cells still totaled $120,000; however, these costs are now traceable to each cell.

Required:

Required:

a. Compute the maintenance cost per roll for each type of tubing before JIT is installed.

b. Compute the maintenance cost per roll for each type of tubing after JIT is installed.

c. Explain why the JIT maintenance cost per roll is more accurate than the cost per roll using the traditional approach.

Correct Answer:

Verified

View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Q138: Eva Rodriguez, chairwoman of Wiccan Industries, had

Q139: Clinton Corp. is a manufacturer of equipment

Q140: Laramie Company has a traditional, unit-based cost

Q141: Fast & Furious Company recently implemented a

Q142: Prior to installing a JIT system, PVCTec

Q143: Loganberry Corporation sells a product for $400

Q144: A firm that has implemented JIT had

Q145: MaximumTec has implemented JIT had the following

Q146: Harmonious Manufacturing Company sells a product for

Q147: Explain the difference between acceptable quality level

Unlock this Answer For Free Now!

View this answer and more for free by performing one of the following actions

Scan the QR code to install the App and get 2 free unlocks

Unlock quizzes for free by uploading documents