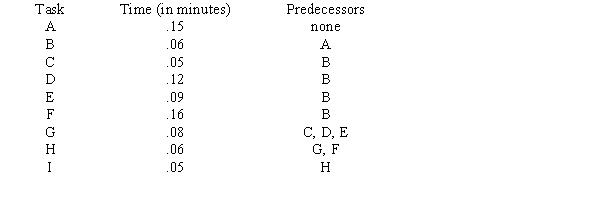

The nine tasks necessary to assemble a vacuum cleaner are listed below. The time to perform each task and the tasks that must immediately precede are also listed. 300 vacuums are needed per hour and 50 minutes per hour are productive.

a.Compute the cycle time per unit in minutes.

b.Compute the minimum number of workstations required.

c.Use the longest-task-time heuristic to balance the production line.

d.Compute the efficiency of the assembly line.

Correct Answer:

Verified

View Answer

Unlock this answer now

Get Access to more Verified Answers free of charge

Q41: _ is vertical expansion of job duties

Q47: Which is not true regarding fixed-position layout?

A)Synonymous

Q62: A small electronics company assembles power supplies

Q63: For the following assembly line data, balance

Q67: Discuss the advantages and disadvantages of utilizing

Q67: A company is setting up an assembly

Q73: An assembly line with 28 operations is

Q75: An assembly line with 28 activities is

Q84: Explain the sociotechnical approach to job design

Q85: Explain the role of ergonomics in job

Unlock this Answer For Free Now!

View this answer and more for free by performing one of the following actions

Scan the QR code to install the App and get 2 free unlocks

Unlock quizzes for free by uploading documents