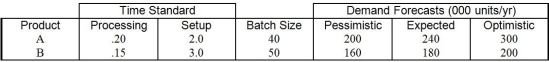

Table 6.2

High Tech,Inc.is producing two types of products: A and B.Both are produced at the same sawing operation.Because of demand uncertainties,the operations manager obtained three demand forecasts (pessimistic,expected,and optimistic) .The demand forecasts,batch sizes (units/batch) ,processing times (hr/unit) ,and setup times (hr/batch) follow.  The sawing machines operate on two 8-hour shifts,5 days per week,and 50 weeks per year.The manager wants to maintain a 10 percent capacity cushion.

The sawing machines operate on two 8-hour shifts,5 days per week,and 50 weeks per year.The manager wants to maintain a 10 percent capacity cushion.

-Using the information from Table 6.2,what is the minimum total number of hours required of sawing equipment for the next year?

A) fewer than 85,000 hours

B) more than 85,000 but fewer than 95,000

C) more than 95,000 but fewer than 105,000

D) more than 105,000 hours

Correct Answer:

Verified

Q48: A wait-and-see capacity strategy does all of

Q52: An expansionist capacity strategy does all of

Q54: Table 6.2

High Tech,Inc.is producing two types of

Q55: Which one of the following statements about

Q56: A wait-and-see capacity strategy:

A) involves small, frequent

Q58: Table 6.1

The Union Manufacturing Company is producing

Q69: The single milling machine at Stout Manufacturing

Q72: A well-educated operations manager used the capacity

Q77: A well-educated operations manager used the capacity

Q78: The time required to change a machine

Unlock this Answer For Free Now!

View this answer and more for free by performing one of the following actions

Scan the QR code to install the App and get 2 free unlocks

Unlock quizzes for free by uploading documents